Preparation method of liquid cellulase

A cellulase and liquid technology, applied in the field of liquid cellulase production, can solve the problems of large power consumption, large consumption of raw material microcrystalline cellulose and lactose, low equipment utilization rate, etc., so as to reduce costs and improve equipment utilization rate. , the effect of high-yield preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

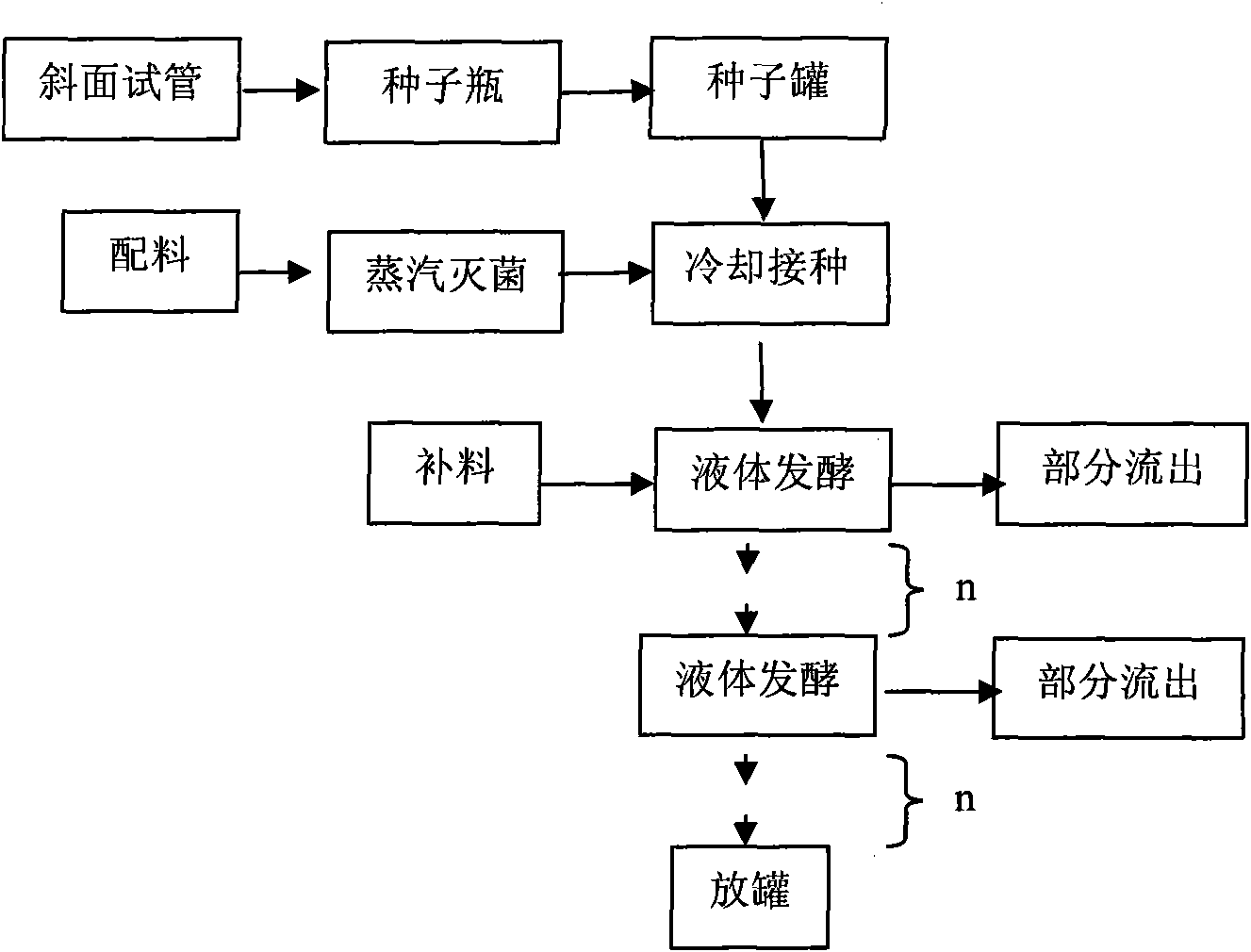

Method used

Image

Examples

Embodiment 1

[0029] Trichoderma viride (China Industrial Microorganism Culture Management and Preservation Center, CICC 40635) was used to produce cellulase by semi-continuous fermentation of microcrystalline cellulose in a 250mL Erlenmeyer flask with a liquid volume of 50mL, cyclic fermentation 10 times, and a fermentation temperature of 30 ℃, and the rotation speed is 250 rpm.

[0030] Wherein the fermentation medium contains 3% microcrystalline cellulose, 3% corn steep liquor, 3% urea, 4% ammonium sulfate and 4% dipotassium hydrogen phosphate.

[0031] Release 50% of the culture medium after the first fermentation for 96 hours, and then add an equal amount of fresh culture medium. Release 50% of the culture medium every 24 hours thereafter, and then add an equal amount of fresh culture medium, and stop the fermentation after a total of 10 cycles of fermentation. The ingredients in the supplemented medium are 3% microcrystalline cellulose, 2% corn steep liquor, 1% urea, 2% ammonium sulf...

Embodiment 2

[0034] Use Trichoderma viride (China Industrial Microorganism Culture Collection Center, CICC 41495) in a 50L stainless steel standard fermenter with a liquid volume of 30L. Microcrystalline cellulose is used for semi-continuous fermentation to produce cellulase, and the fermentation cycle is 10 times, the fermentation temperature is 30°C, the stirring speed is 300 rpm, the ventilation is 0.8vvm, and the tank pressure is 0.05Mpa.

[0035] Wherein the fermentation medium contains 2% microcrystalline cellulose, 2% corn steep liquor, 3% urea, 5% ammonium sulfate, 2% dipotassium hydrogen phosphate and 0.001% foam enemy in the fermentation medium.

[0036] After 85 hours of first fermentation, release 30% of the culture medium, and then add an equal amount of fresh medium. Release 20%, 30%, ... 80% of the culture solution every 24 hours, add an equal amount of fresh medium, cycle fermentation for 7 times, then release 60% of the culture solution every 24 hours, and at the same time...

Embodiment 3

[0039] Use Trichoderma viride (China Industrial Microorganism Culture Collection Center, CICC 40492) in a 1T stainless steel standard fermenter with a liquid volume of 750L. The cellulase is produced by semi-continuous fermentation of microcrystalline cellulose, the fermentation cycle is 10 times, the fermentation temperature is 30°C, the stirring speed is 200 rpm, the ventilation is 0.7vvm, and the tank pressure is 0.05Mpa.

[0040] The fermentation medium contains 2% microcrystalline cellulose, 2% corn steep liquor, 12% urea, 2.5% ammonium sulfate, 2.5% dipotassium hydrogen phosphate, and 0.001% foam enemy.

[0041] After 75 hours of first fermentation, release 40% of the culture medium, and then add an equal amount of fresh culture medium. After that, release 40% of the culture medium every 24 hours, and then add an equal amount of fresh culture medium, and finish the fermentation after a total of 12 cycles of fermentation. The ingredients in the supplemented medium are 2%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com