Method for preparing all cotton stalk cellulose by adopting mechanical-active oxygen method

A technology of active oxygen and oxidation, which is used in fiber raw material processing, inorganic compound addition, cellulose raw material pulping, etc. Spots and rot spots are not easy to separate and other problems, to achieve the effect of low cost, good whiteness, and elimination of stiff spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

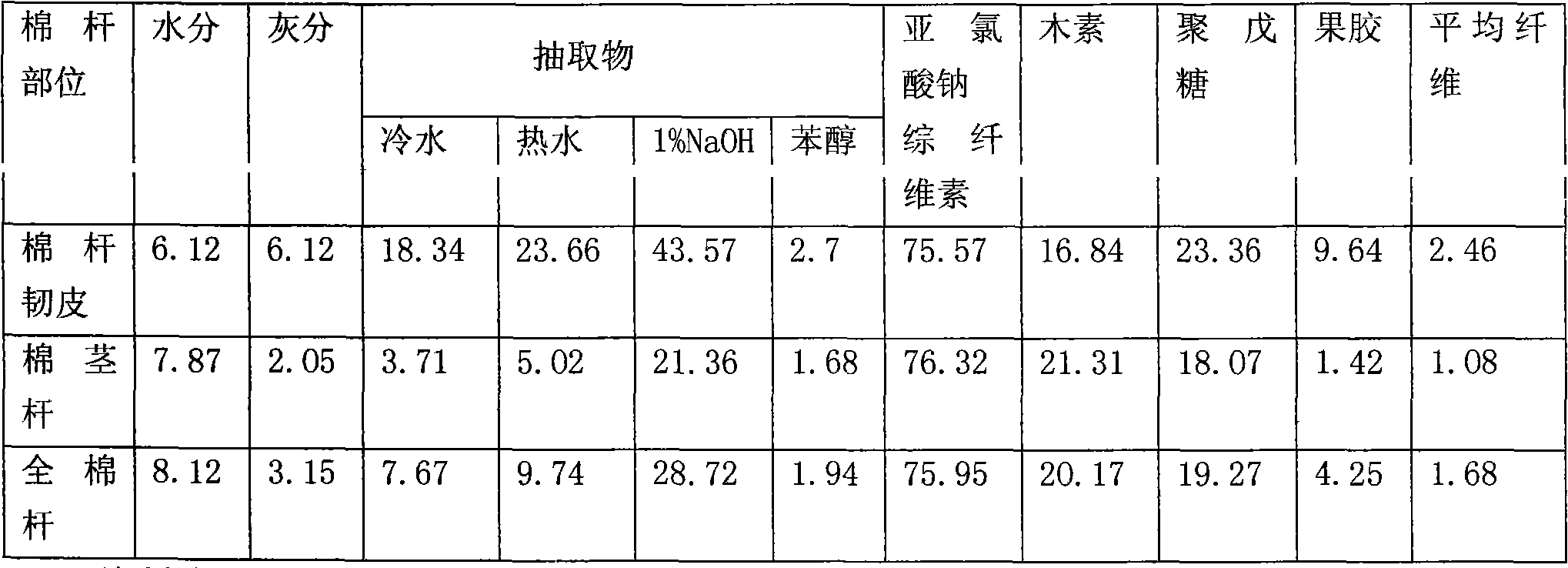

Image

Examples

Embodiment

[0029] 1. Raw material preparation:

[0030] Arranging the cotton stalks, removing debris, tearing and crushing the cotton stalks with a tearing machine, and kneading them into velvet-like materials with a kneading machine.

[0031] 2. Preparation of fiber:

[0032] 2.1 Pre-oxidation treatment: Put the velvet material into the pre-oxidation reactor equipped with a mechanical deconcentrator, add the prepared impregnating solution for pre-oxidation reaction, and start the mechanical decomposer to stir and decompose the material; the pre-oxidation reaction temperature The temperature is 70-80°C, and the pre-oxidation reaction time is controlled at 40-80 minutes. The present embodiment is 50~60 minutes.

[0033] The composition of the impregnation solution is based on the weight ratio of dry cotton stalks: the content of active oxygen A is 3-10%, the content of active oxygen B is ≥2.5 μmol / L, the content of active oxygen C is ≥3 μmol / L, and the content of active oxygen D The co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com