Preparation method of Pr<3+> doped (Yx La (1-x)) 2 O3 luminescent material

A technology of luminescent material and doping amount, which is applied in the field of preparation of Pr3+ doped 2O3-based phosphors and transparent ceramics, can solve the problems such as the great influence of energy level structure, achieve good optical performance, high light output, and improve light output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In the present embodiment, preparation (Y 1x La x ) 2 o 3 :Pr 3+ The specific process of phosphor powder and flashing ceramics is as follows:

[0032] 1. (Y 1-x La x ) 2 o 3 :Pr 3+ Powder Preparation Process

[0033] (a) Solid phase method

[0034] a. Using high-purity Pr 6 o 11 (99.99%), Y 2 o 3 (99.99%) and La 2 o 3 (99.99%) as raw material, with Y 2 o 3 as the matrix material, La 2 o 3 As an adjuvant, Pr 3+ as the active ion. The mass ratio of the three is according to the chemical formula Y 2-2x-2y La 2x PR 2y o 3 Based on, x=0.1 in the formula, y=0.02; La 2 o 3 The doping amount is 10at.% (mole percent), Pr 6 o 11 The doping amount is 2at%;

[0035]b. Mix the prepared powders, ball mill them in ethanol for 20 hours, and dry them at 95°C;

[0036] c. Then place it in a calciner for pretreatment at 1100°C for 5 hours; put it in a ball mill for 20 hours, then dry it at 95°C and granulate it to obtain Y 2-2x-2y La 2x PR 2y o 3 Nano po...

Embodiment 2

[0048] The process step of the present embodiment is basically the same as the above-mentioned embodiment 1, the difference is:

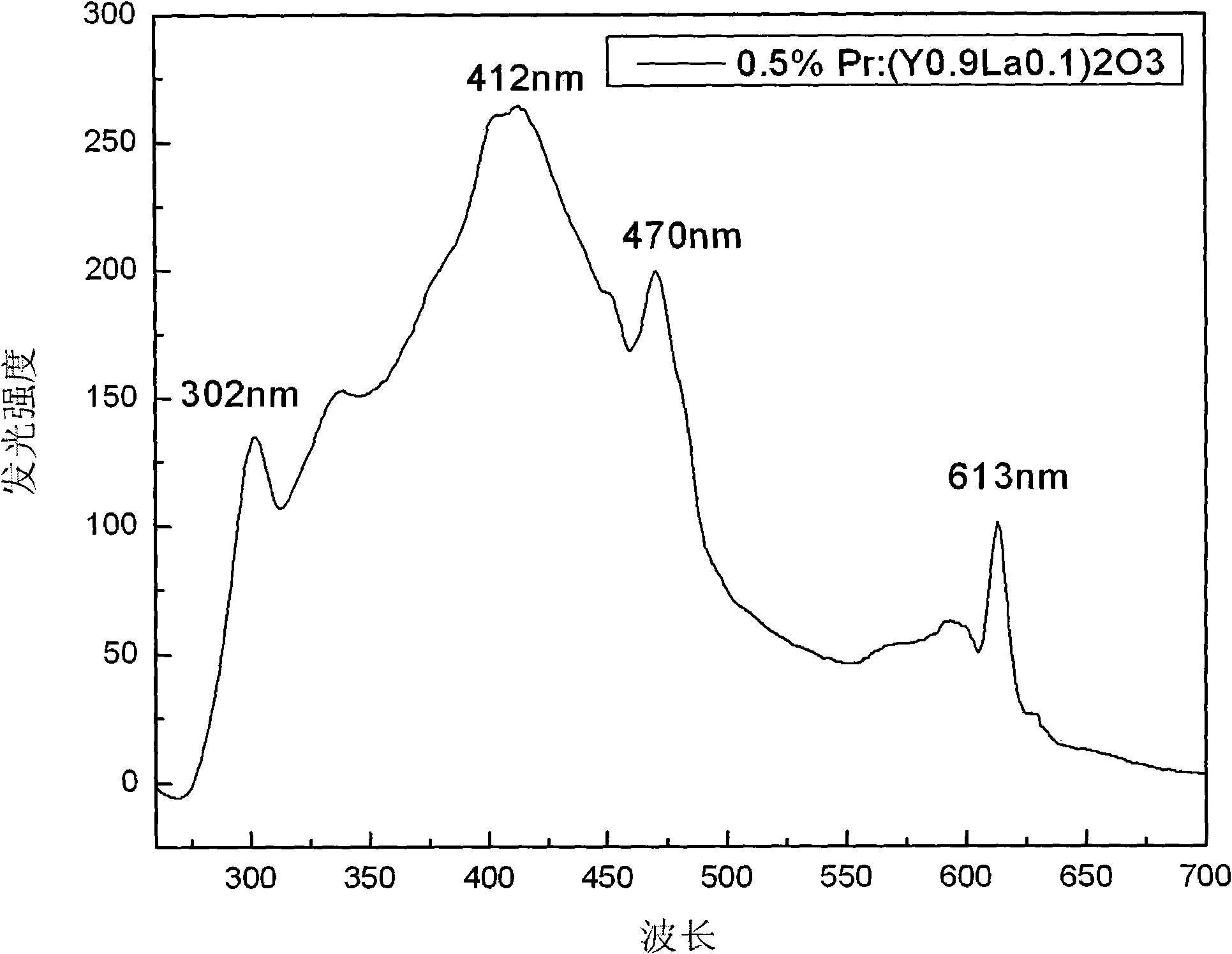

[0049] Y 2-2x-2y La 2x PR 2y o 3 In the formula, x=0.1, y=0.005; La 2 o 3 The doping amount is 10at.% (mole percent), Pr 6 o 11 The doping amount is 0.5at%; the firing temperature of the powder in the muffle furnace is 900°C; the sintering temperature of the ceramic is 1650°C; finally Y 2-2x-2y La 2x PR 2y o 3 Phosphor and ceramic scintillation materials.

Embodiment 3

[0051] The process step of the present embodiment is basically the same as the above-mentioned embodiment 1, the difference is:

[0052] Y 2-2x-2y La 2x PR 2y o 3 In the formula, x=0.1, y=0.05; La 2 o 3 The doping amount is 10at.% (mole percent), Pr 6 o 11 The doping amount is 5at%; the firing temperature of the powder in the muffle furnace is 900°C; the sintering temperature of the ceramic is 1650°C; finally Y 2-2x-2y La 2x PR 2y o 3 Phosphor and ceramic scintillation materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com