Method for packing separation column and nozzle needle integrated capillary column and manufacturing stopper

A technology of capillary column and manufacturing method, which is applied in the fields of chromatography and mass spectrometry, can solve the problems of capillary separation column filler leakage, cumbersome manufacturing steps, and low sample load, and achieve high column efficiency, simple filling process, and low manufacturing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

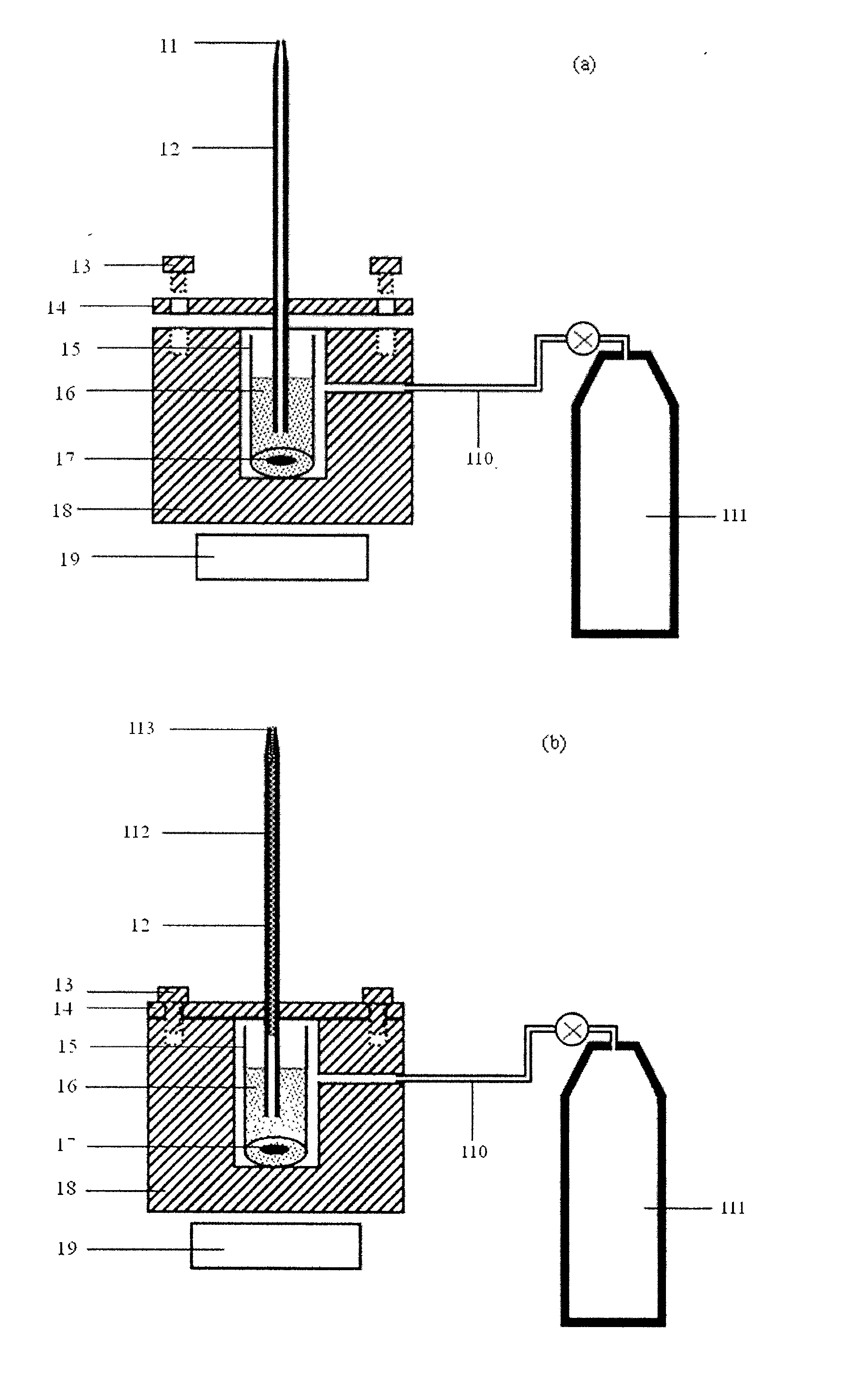

[0022] Packing of the capillary column integrated with the separation column and the electrospray nozzle: use 5mL centrifuge tube 15 to prepare 2mL-5mg / mL-5μm C 18 Reversed-phase filler-methanol homogenate, with magnet 17 placed inside; put the centrifuge tube into the homogenization tank 18, and the homogenization tank is placed on the magnetic stirrer 19, and the speed of 200r / min is maintained; the inner diameter is 75 μm, the tapered 15μm inner diameter, 12cm length capillary column 12 presses figure 1 Insert it into the homogenate solution 16 as shown, and seal the homogenate tank with the sealing screw 13; open the nitrogen pressure reducing valve, and adjust the nitrogen pressure to 0.1MPa; under the nitrogen pressure, the filler slowly moves toward the tapered mouth of the capillary column for 2 hours Finally, the filler is filled with the capillary column. During this process, gradually increase the nitrogen pressure to 1MPa; remove the capillary column from the homog...

Embodiment 2

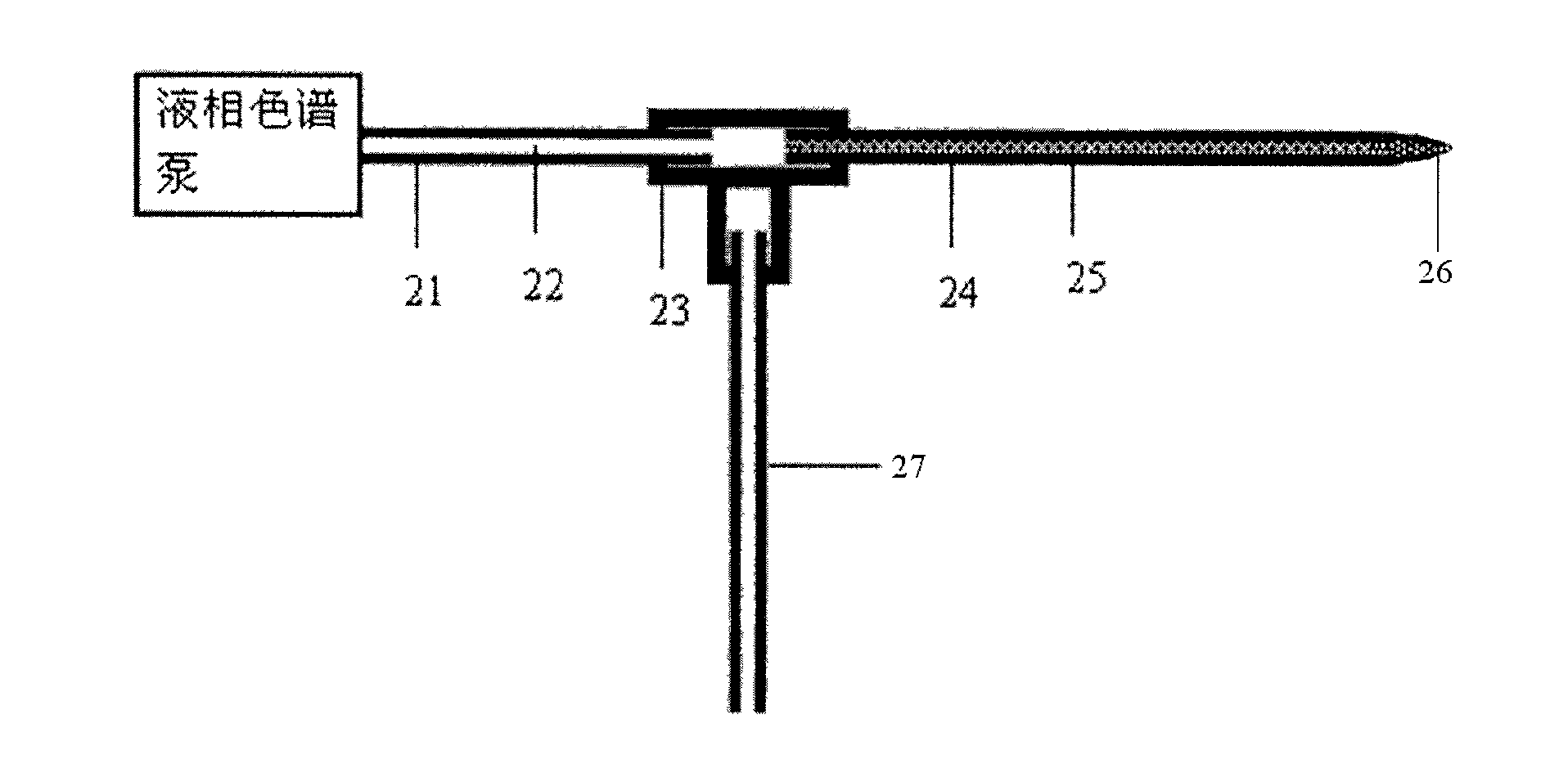

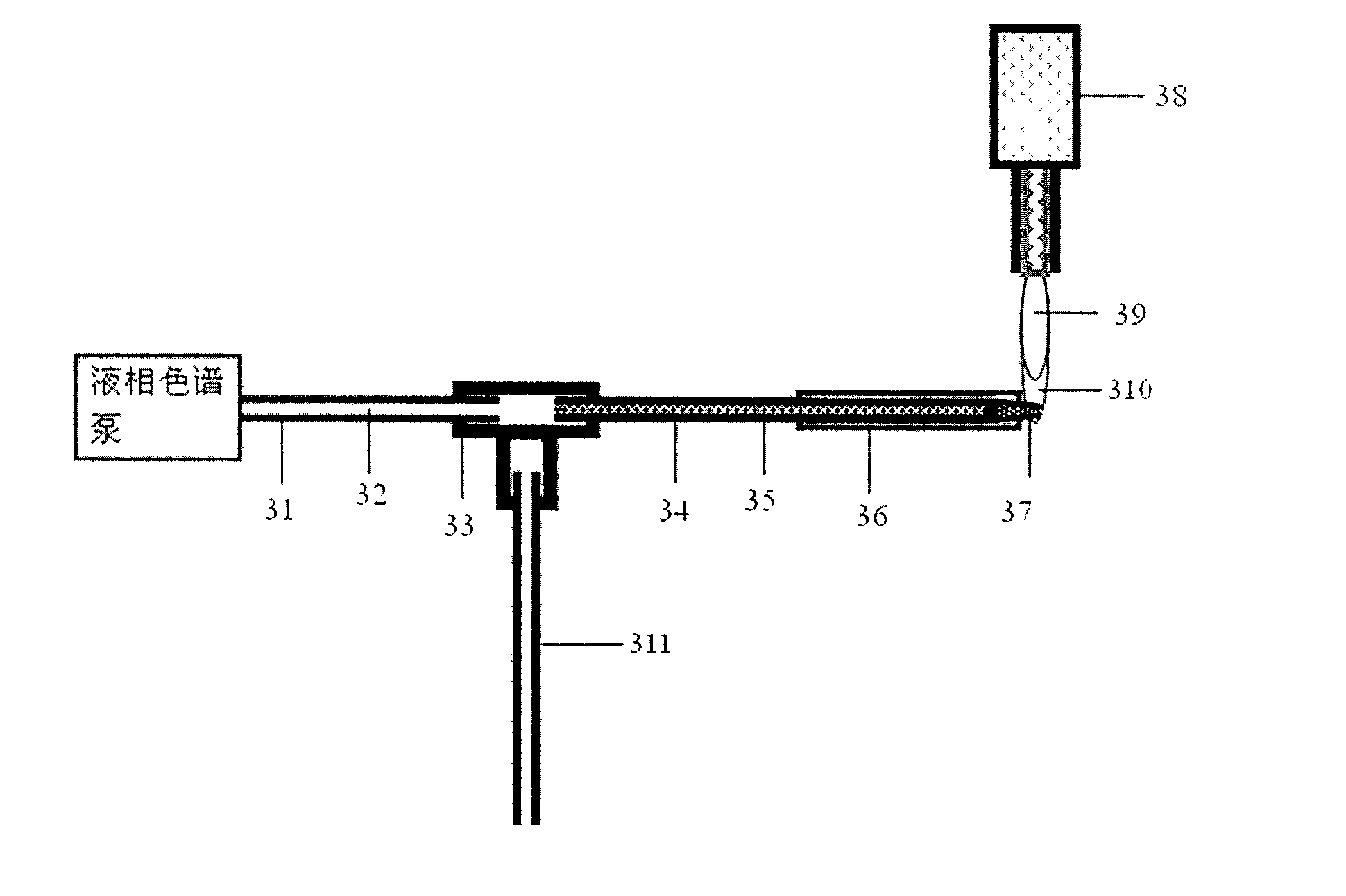

[0024] Production of a capillary plunger integrated with a separation column and a spray needle: Put a stainless steel tube with a length of 3 cm, an inner diameter of 0.5 mm, and an outer diameter of 1.6 mm on the capillary column filled in Example 1, and use a micro tee 33 to seal the capillary column 34 is connected to the liquid chromatography pump, and one end of the micro-tee is connected to a shunt capillary with an inner diameter of 250 μm and 50 cm; the mobile phase of the liquid chromatography pump is kept at 0.01 mL / min; Sinter the packing at the conical port of the capillary to form a sintered plug with a length of 0.25 mm; reduce the flow rate of the mobile phase to zero, and remove the capillary column.

Embodiment 3

[0026]The capillary column and stopper integrated with the separation column and spray needle prepared according to implementation 1 and 2 are used for actual sample analysis, and the results are as follows Figure 5 Show. As a comparison, under the same conditions, the same sample was analyzed using a self-assembled plug capillary column, the results are as follows Figure 6 Show. Comparing the two figures, it can be seen that the sintered plug capillary column with integrated separation column and injection needle prepared by the present invention has better separation effect.

[0027] Chromatographic conditions: mobile phase A, 0.1% formic acid-2% acetonitrile, mobile phase B, 0.1% formic acid-80% acetonitrile; within 90min, mobile phase B increases linearly from 5% to 50%, and within 10min, mobile phase B increases linearly by 100% %, flow rate 200nL / min. Mass spectrometry conditions: m / z=400-1600 full scan, select 6 strongest peaks for secondary scan after a full scan ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com