Method for repairing and etching polysilicon

A technology of polysilicon and plasma, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of lower yield, unevenness, and substrate damage of source and drain, so as to improve yield and ensure reliability , the effect of good etching uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

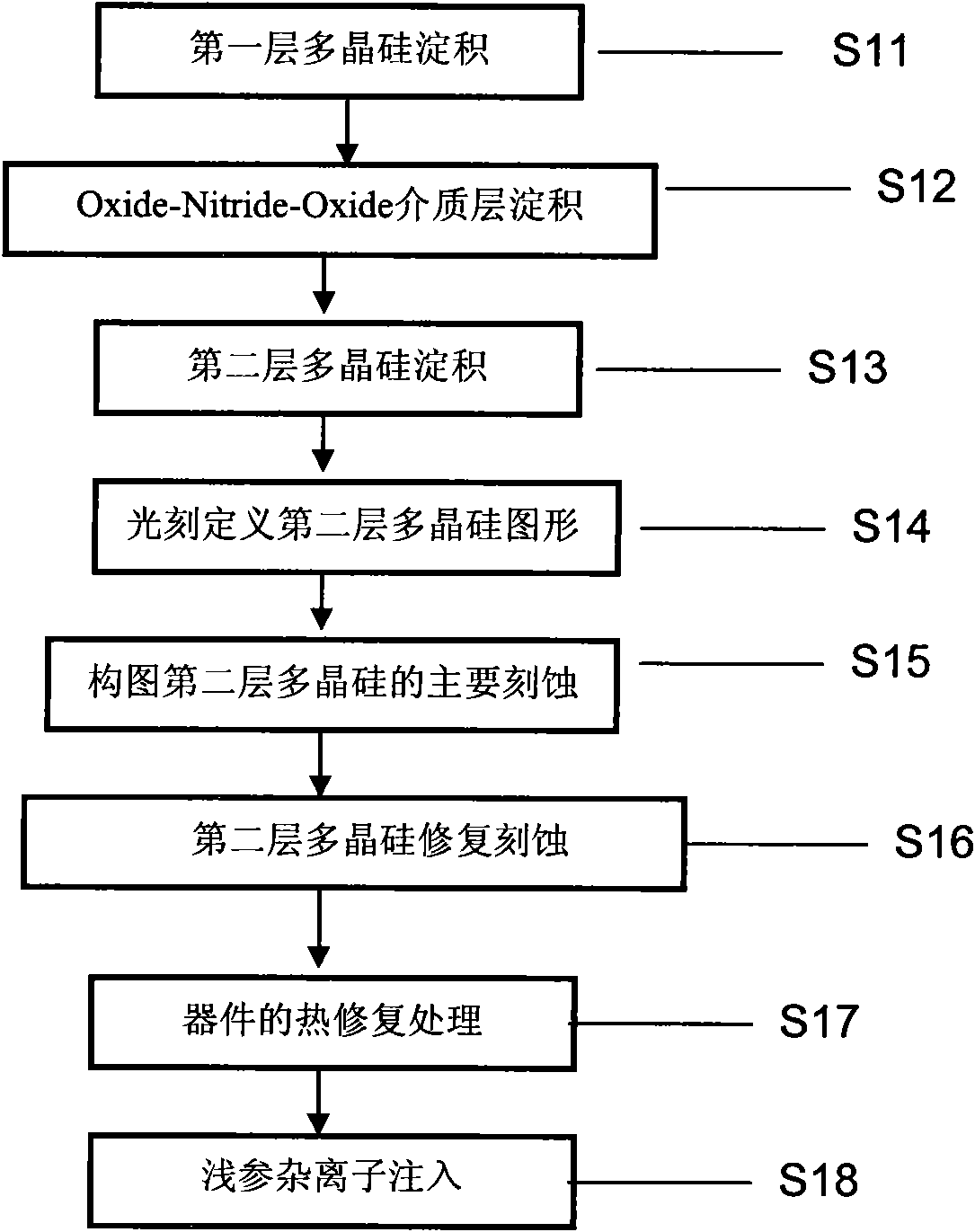

[0011] This embodiment describes the repair etching method of the control gate polysilicon of EEPROM under the 0.35um process technology generation, according to figure 1 The manufacturing process of the gate of the shown EEPROM, in the manufacturing process of the EEPROM, the main etching step of S16 is mainly to pattern and etch the second layer of polysilicon and the Oxide-Nitride-Oxide dielectric layer under the second layer of polysilicon, wherein The substrate silicon is used as the etching stop layer, and the second layer of polysilicon is repaired and etched after step S16, and the second layer of polysilicon is used to form the control gate of the EEPROM.

[0012] The polysilicon etching method of this embodiment is completed in a kind of plasma dry etching equipment. During the etching process, oxygen O2 flows into the equipment chamber simultaneously. 2 and tetrafluoromethane CF 4 Two gases, O 2 with CF 4 The flow ratio scope of gas is 4: 1-6: 1, preferred O in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com