Preparation method of PYP

A technology of pyridine alkynyl butanesulfonate and betaine, which is applied in the field of preparation of pyridine betaine alkynyl butanesulfonate, can solve the problems such as no public reports on the preparation method of pyridine alkynyl butanesulfonate, and achieve leveling Wide range, high product yield and good brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

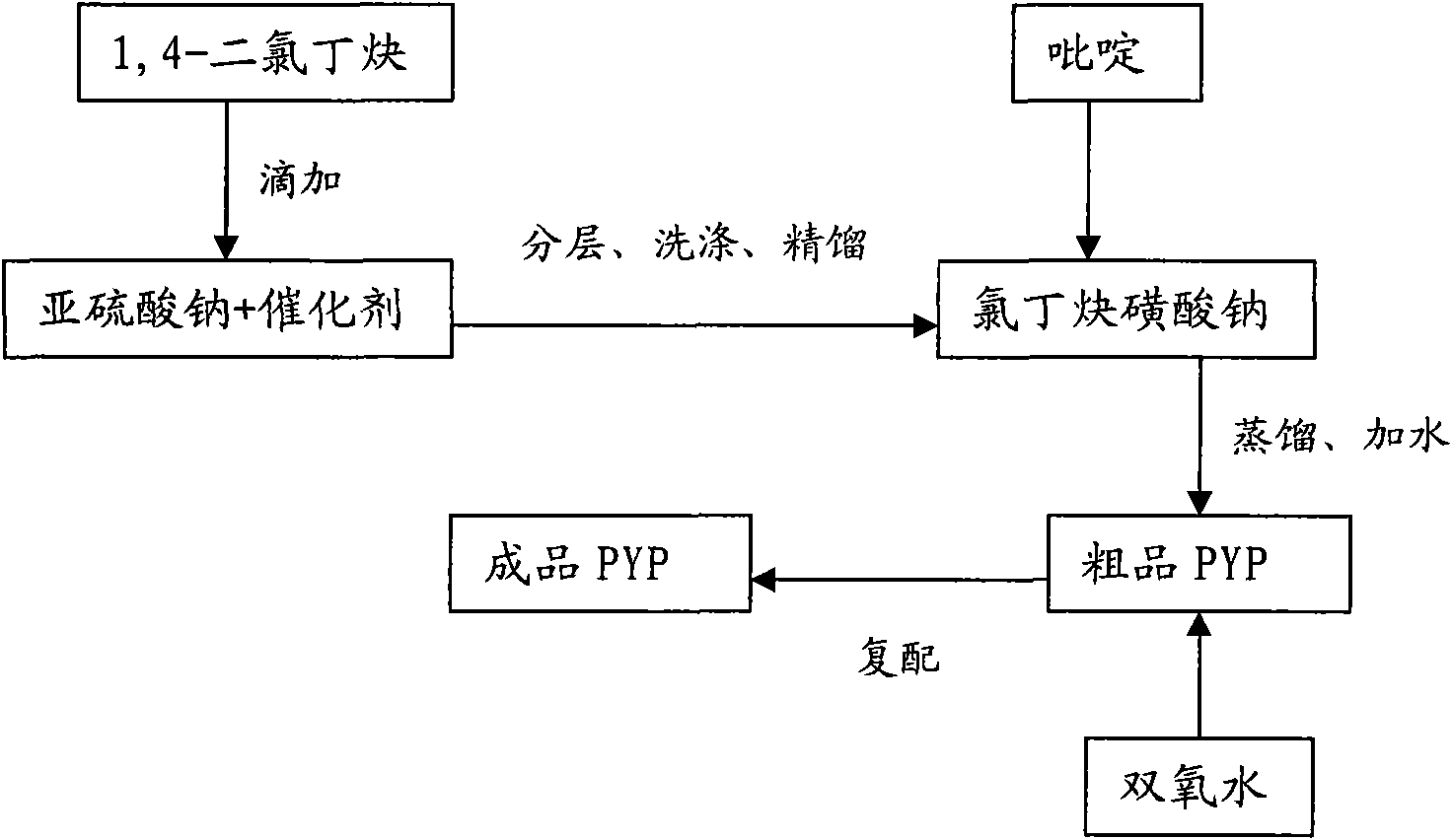

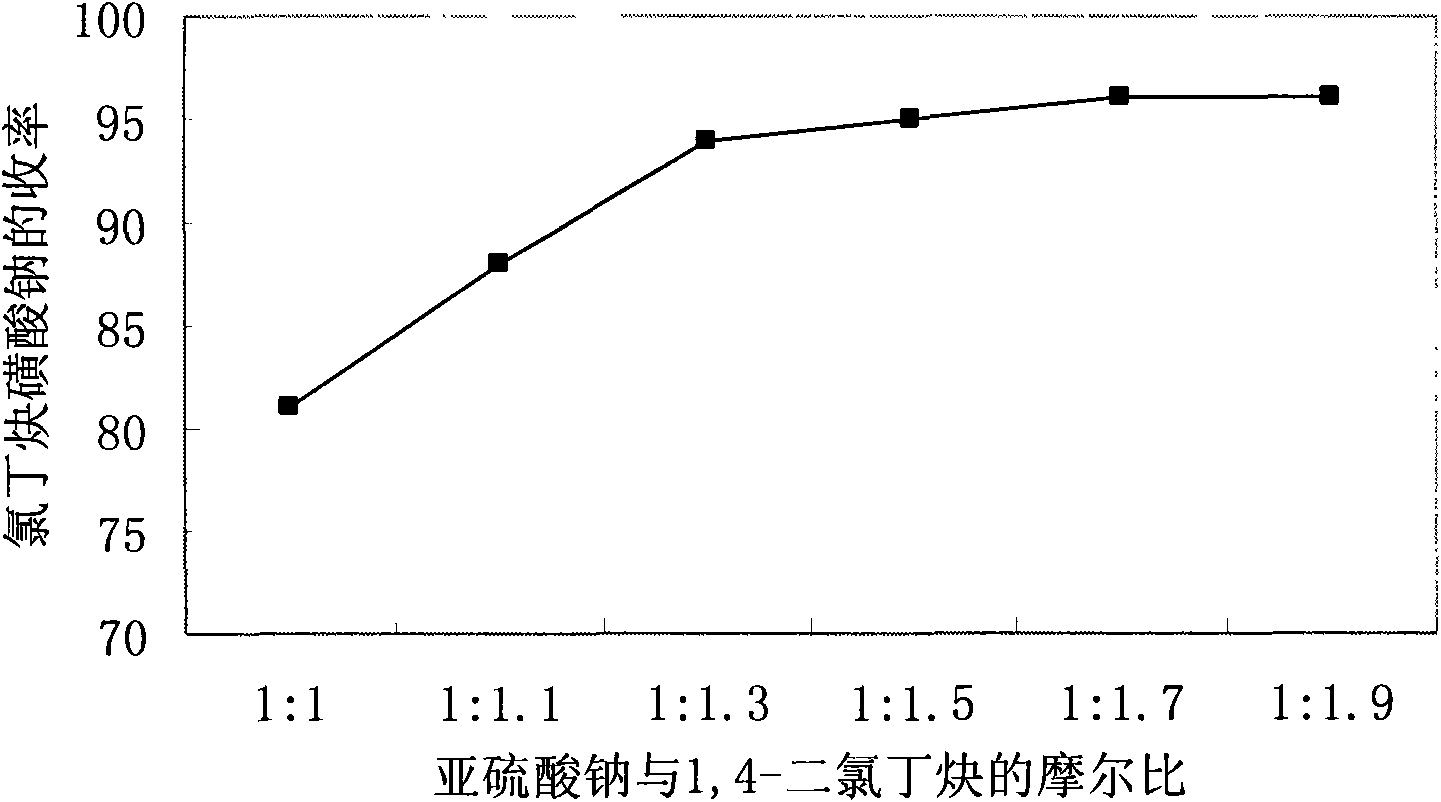

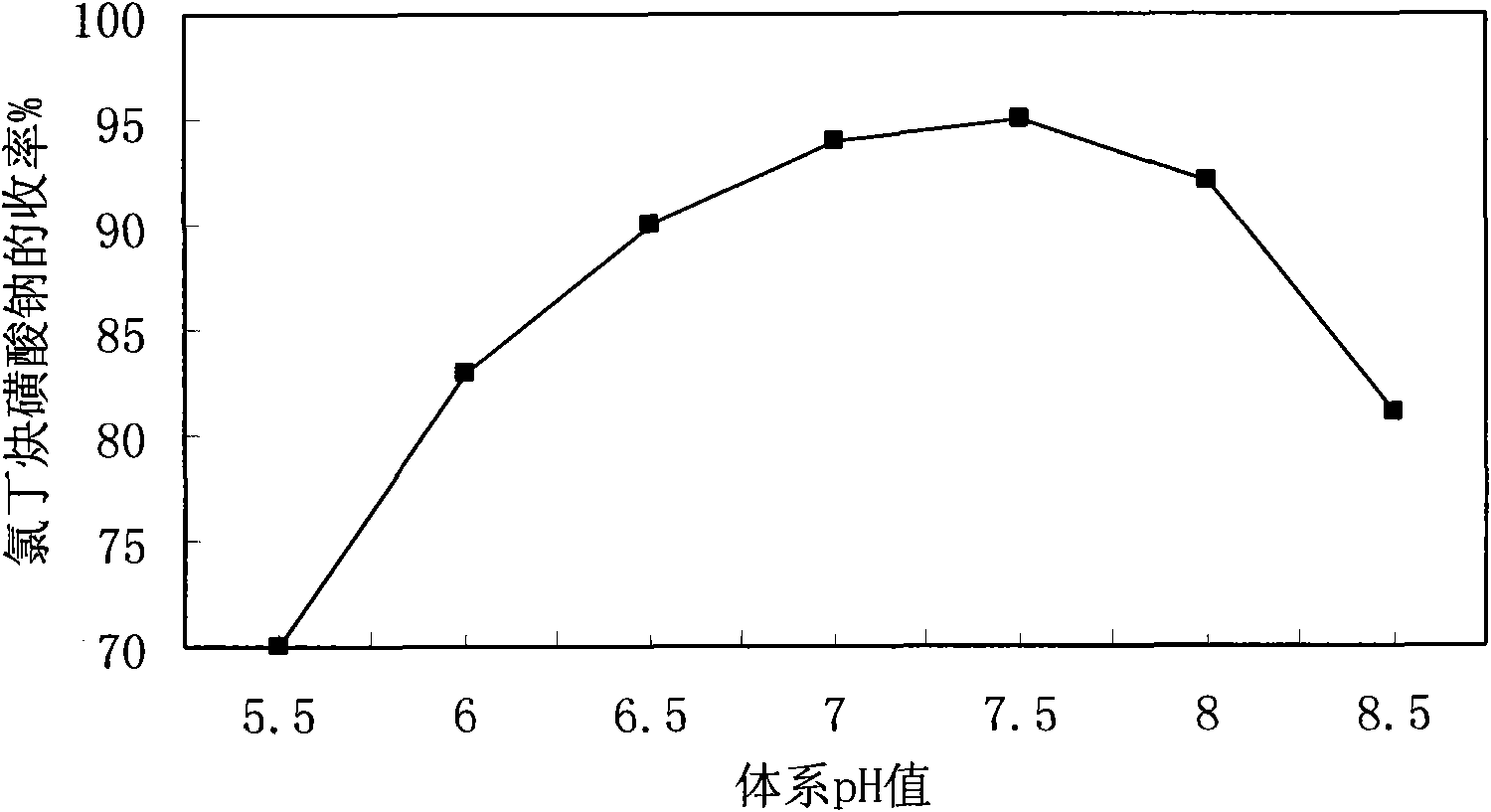

[0037]The preparation method of pyridine betaine (PYP) of alkyne butyl sulfonate of the present invention, comprises the following steps successively, 1., preparation of sodium chlorobutyn sulfonate: get sodium sulfite to be dissolved in water, be made into the solution that concentration is 10%, slowly drop Hydrochloric acid, adjust the pH to 6.5-8, add the catalyst disodium edetate, slowly raise the temperature to 40-70°C, add 1,4-dichlorobutyne dropwise; add alkali to keep the pH at 6.5-8, pass Add an inert gas as a protective gas; after the dropwise addition, keep it warm at 40-70°C for 4-10 hours; after the reaction, let it stand for stratification, separate the upper liquid and recover it for later use; take the lower liquid, vacuum dehydrate, and remove the water The mass accounts for 80% of the total solution; after the dehydration finishes, add methanol to the mixture, stir at 55°C for 30 minutes, filter to obtain filter cake and filtrate; at 55°C, wash the filter cake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com