Polymer microsphere as well as preparation method and application thereof

A polymer and microsphere technology, applied in dyeing, textile and papermaking, etc., can solve the problems of poor light fastness and water immersion fastness, structural damage, etc., and achieve good brightness, improved anti-aging performance, light fastness and water fastness. The effect of increasing the degree of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

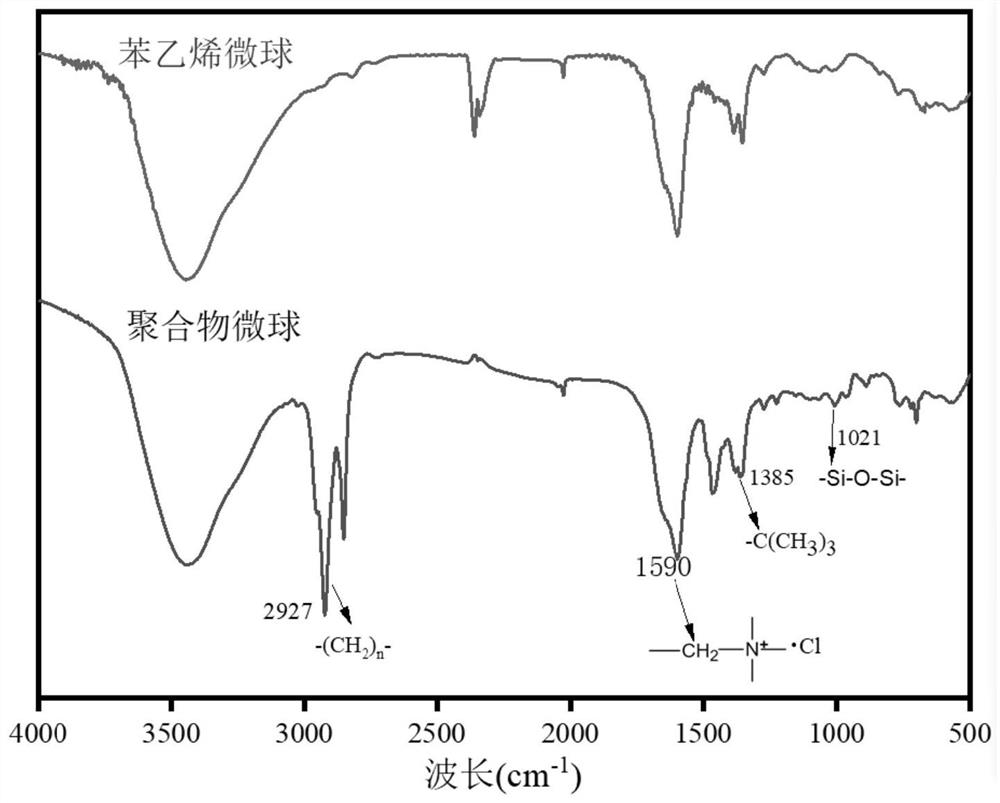

[0034] One aspect of the present invention provides a method for preparing polymer microspheres, the method comprising the following steps:

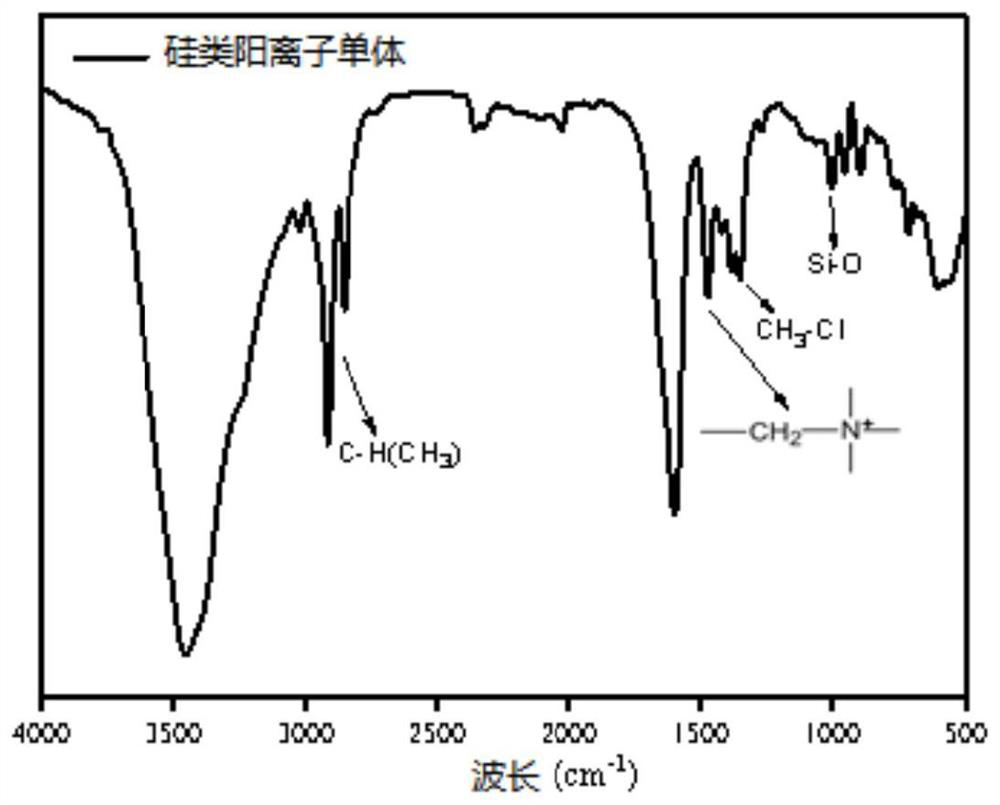

[0035] (1) Stir and mix silicon-containing methylamine, chloropropene and absolute ethanol, then heat to 40-55°C under nitrogen atmosphere for 24-30h, and then perform vacuum rotary evaporation to remove small molecular low-boiling substances to obtain yellow transparent liquid, then cooled to obtain a white solid, which was washed, recrystallized, vacuum filtered and vacuum dried in sequence to obtain a silicon cationic monomer;

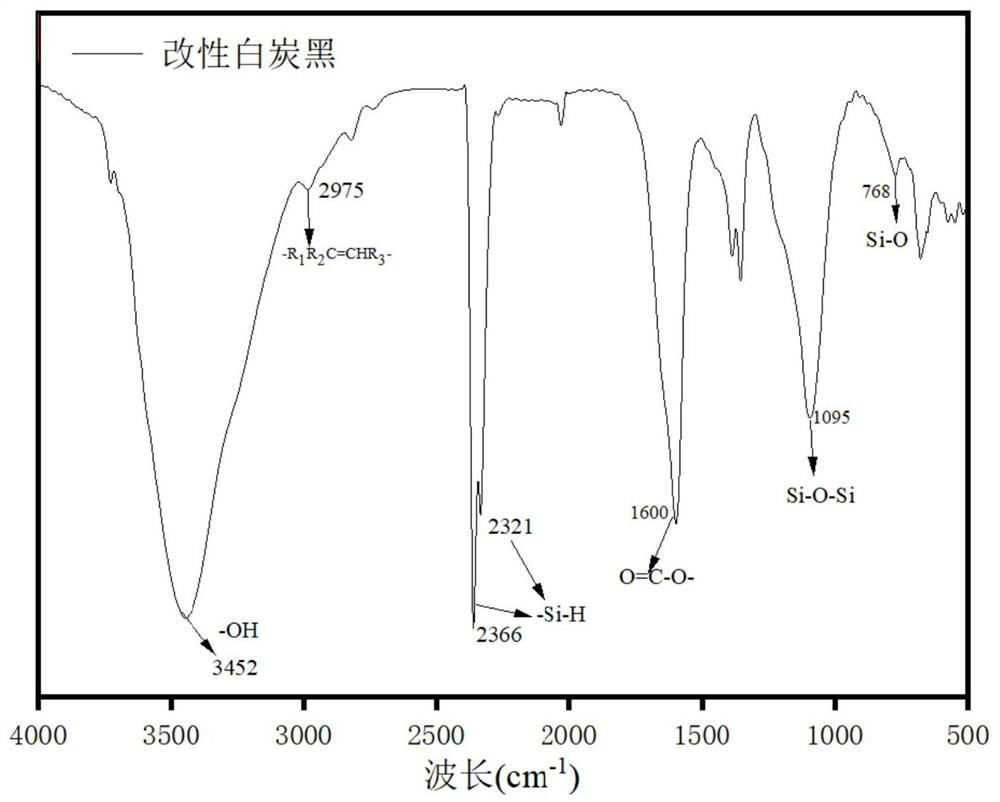

[0036] (2) Add hydrophilic white carbon black to the ethanol aqueous solution, the weight ratio of the hydrophilic white carbon black to the ethanol aqueous solution is 1: (20-50), stir and disperse, and then add silane The coupling agent is heated to 100-120°C for condensing and reflux. The time for condensing and reflux is 2.5-4 hours. After the condensing and reflux is completed, cool to room temperature, s...

Embodiment 1

[0080] (1) When equipped with a stirrer, a thermometer, a reflux condenser (the upper end is equipped with a calcium chloride drying tube) and N 2 Add 11.727g N-(trimethylsilyl) dimethylamine and 22.956g chloropropene in the drying four-necked flask of protective device (the mol ratio of N-(trimethylsilyl) dimethylamine and chloropropene is 1: 3), then add 37.4576g of absolute ethanol, and mix evenly under electric stirring (the ratio of the weight of absolute ethanol to the weight of N-(trimethylsilyl)dimethylamine and chloropropene is 1.08:1) , then feed nitrogen and heat to 45°C for 24 hours under a nitrogen atmosphere, then use a rotary evaporator to carry out rotary evaporation under reduced pressure (the pressure of rotary evaporation is 0.11mPa, the temperature of rotary evaporation is 72°C, and the time of rotary evaporation is 5h) Remove small molecules and low boilers to obtain a yellow transparent liquid, then place it in a freezer to cool to obtain a white solid, w...

Embodiment 2

[0084] (1) When equipped with a stirrer, a thermometer, a reflux condenser (the upper end is equipped with a calcium chloride drying tube) and N 2 Add 11.727g N-(trimethylsilyl) dimethylamine and 20.660g chloropropene in the drying four-necked flask of protective device (the mol ratio of N-(trimethylsilyl) dimethylamine and chloropropene is 1: 2.7), then add 34.0064g of absolute ethanol, and mix evenly under electric stirring (the ratio of the weight of absolute ethanol to the weight of N-(trimethylsilyl)dimethylamine and chloropropene is 1.05:1) , then feed nitrogen and heat to 40°C for 30h under a nitrogen atmosphere, then use a rotary evaporator to carry out rotary evaporation under reduced pressure (the pressure of rotary evaporation is 0.14mpa, the temperature of rotary evaporation is 65°C, and the time of rotary evaporation is 3.5h ) to remove small molecule low boilers to obtain a yellow transparent liquid, then place it in a freezer to cool to obtain a white solid, was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com