Waste heat boiler of shot-cleaning type glass kiln

A waste heat boiler and glass kiln technology, applied in the field of boilers, can solve the problems of boiler cold and heat damage, boiler corrosion, large energy consumption, etc., and achieve the effects of strong intermolecular adsorption, ultra-fine ash particles, and strong electrostatic adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

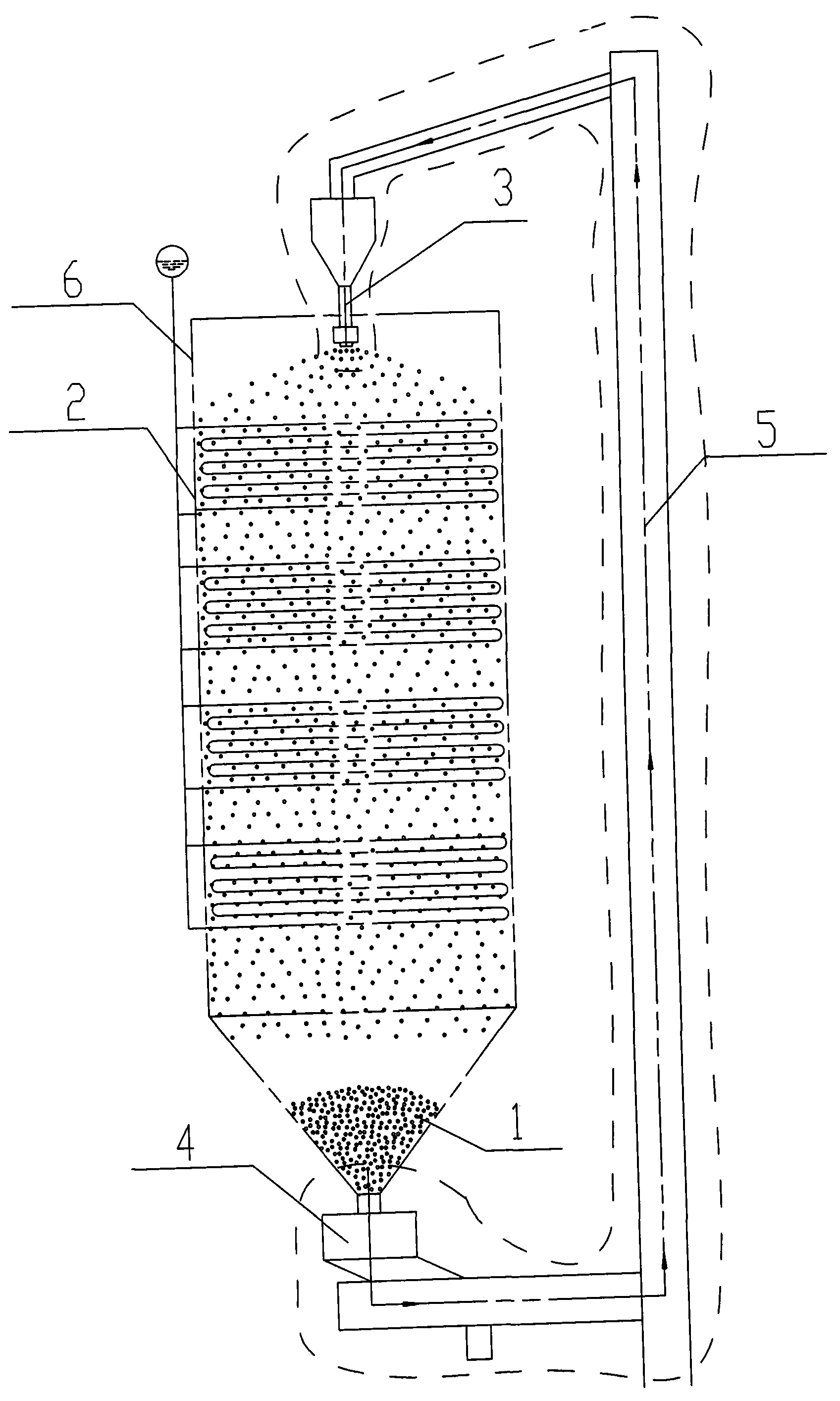

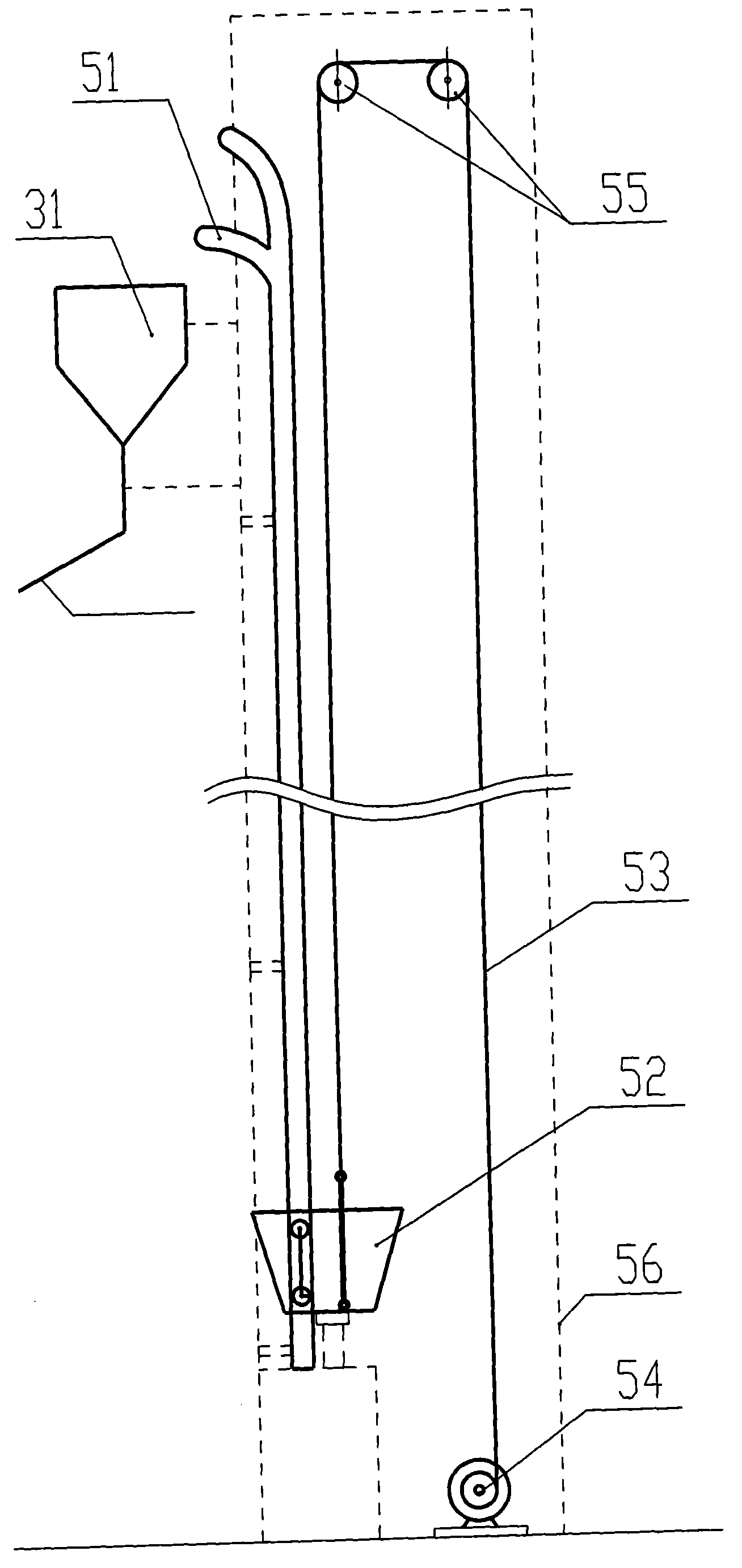

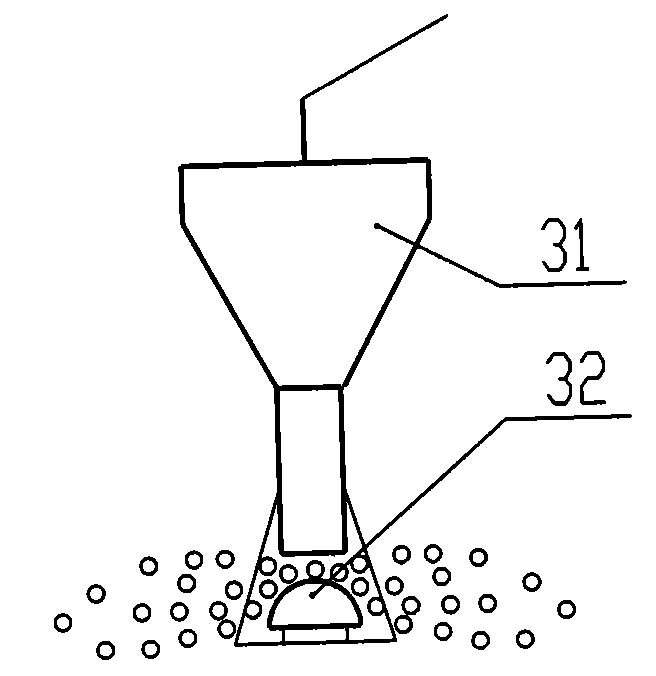

[0029] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, the present invention mainly consists of a boiler heating surface 2, a boiler flue gas channel 6, and a boiler dust removal device.

[0030] Boiler heating surface 2: It is composed of serpentine tube group. The heated water or steam flows inside the tube, and the high-temperature ash-containing flue gas flows out of the tube. The function is to efficiently transfer the high-temperature physical heat on the flue gas side to the water or steam inside the tube. The thermal energy or potential energy that makes the water or steam in the pipe have a certain utilization value.

[0031] Boiler flue gas channel 6: A sealed channel is formed around the heating surface of the boiler, forcing the flue gas to pass through the heating surfaces of the boiler at all levels one by one, and form a furnace top and bottom at the top and bottom of the boiler that can meet t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com