Liquid diary products containing lutein ester and cryptoxanthin and production method thereof

A technology of zeaxanthin and lutein ester, which is applied in the direction of dairy products, milk preparations, food preparation, etc., can solve the problems of difficult application of liquid dairy products, no products on the market, and low purity of raw materials, so as to prevent aging Eye macular disease, eye health care, eye fatigue relief effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1, low-fat milk containing lutein ester and zeaxanthin and production method thereof:

[0040] The raw material formula of the low-fat milk containing lutein ester and zeaxanthin of the present embodiment is (parts by weight):

[0041] Low-fat milk 99.825

[0042] Lutein ester + zeaxanthin raw material 0.02

[0043] Vitamin E 0.002

[0044] Single and double glycerides 0.040

[0045] Monoglycerides of fatty acids 0.100

[0046] Sodium stearoyl lactylate 0.015

[0047] Carrageenan 0.012

[0048] The production method of the low-fat liquid milk containing lutein ester and zeaxanthin of the present embodiment mainly comprises:

[0049] 1) Pasteurize low-fat milk (fresh raw milk can be centrifuged and standardized according to conventional operations to prepare low-fat milk): pasteurize at 80-90°C for 15 seconds; cool to 1-25°C, spare;

[0050] 2) Ingredients: heat 30% to 35% of the total formula milk to 60-75°C, add emulsifier, functional ingredients (lu...

Embodiment 2

[0055] Embodiment 2, full-fat flavored milk containing lutein ester and zeaxanthin and production method thereof:

[0056] The raw material formula of the full-fat flavored milk of the present embodiment is (percentage by weight):

[0057] milk 80.0

[0058] Lutein ester + zeaxanthin raw material 0.03

[0059] Vitamin C 0.0015

[0060] Monoglycerides of fatty acids 0.120

[0061] Sodium stearoyl lactylate 0.015

[0062] Soy lecithin 0.010

[0063] Carrageenan 0.010

[0064] Food flavor 0.090

[0065] water balance.

[0066] The production method of the full-fat flavored milk of lutein ester and zeaxanthin in this embodiment is basically the same as that in Example 1, and the whole-fat flavored milk containing lutein ester and zeaxanthin is obtained.

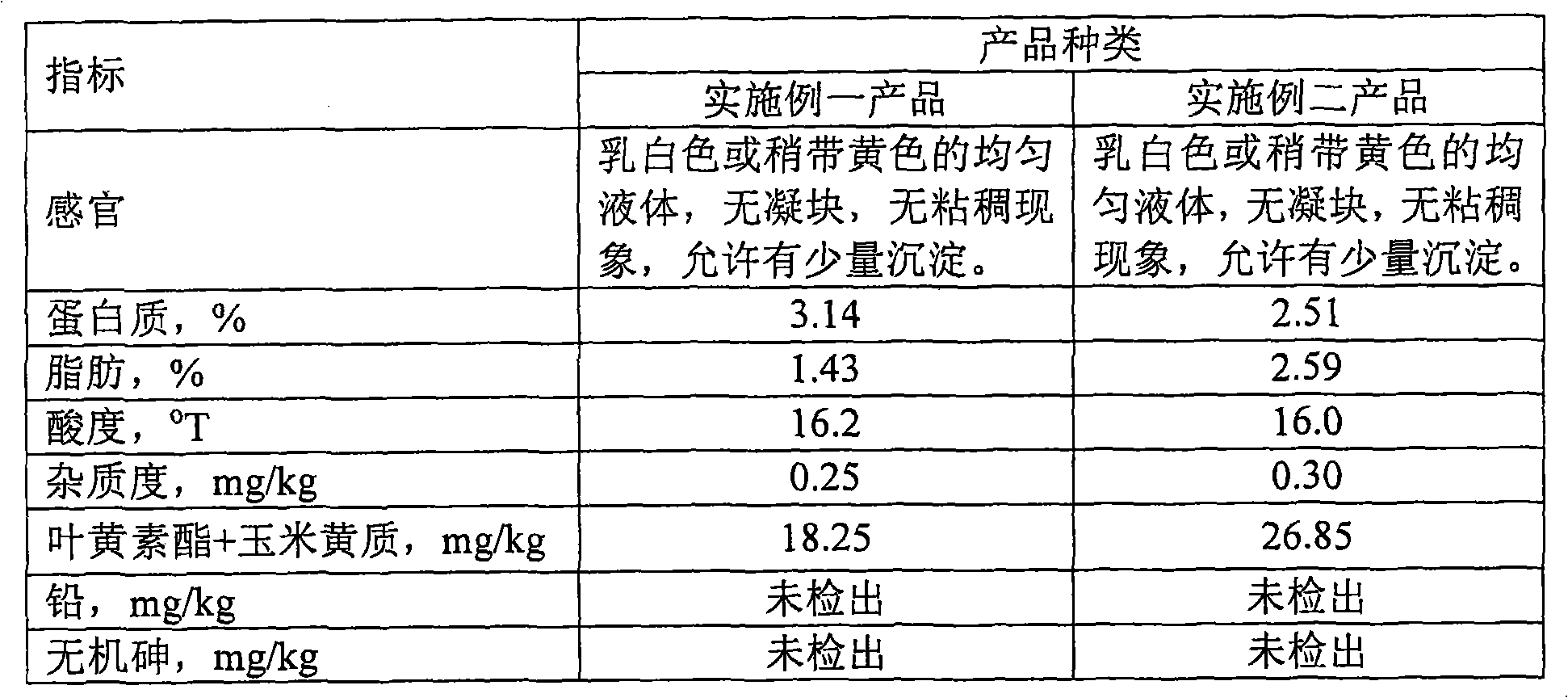

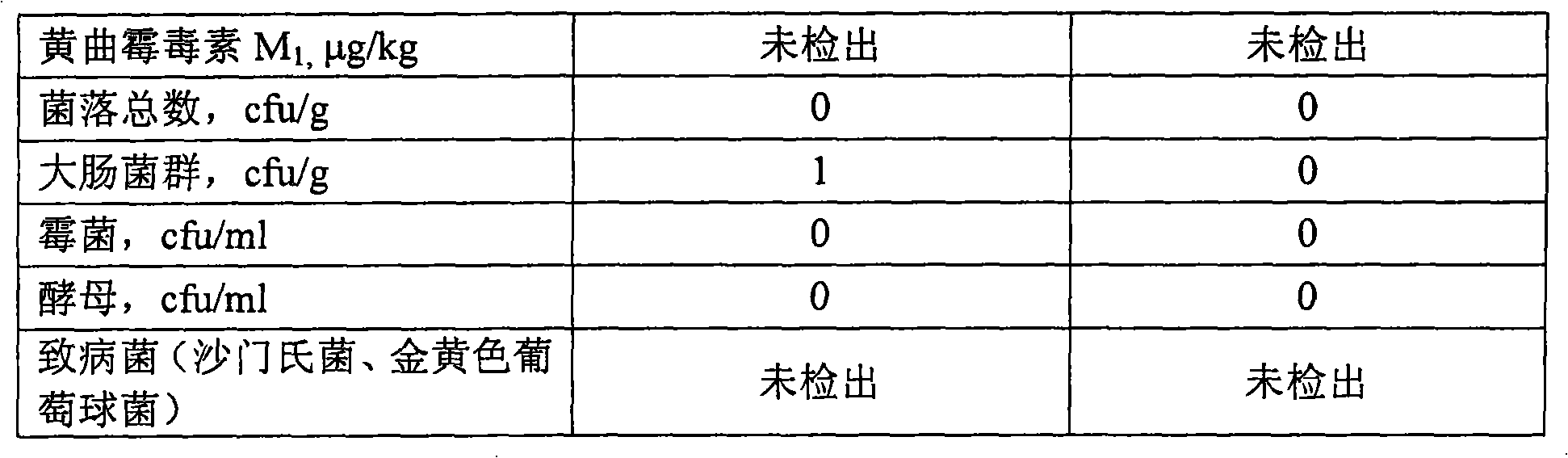

[0067] The product of embodiment one, two is tested, and result is as follows:

[0068]

[0069]

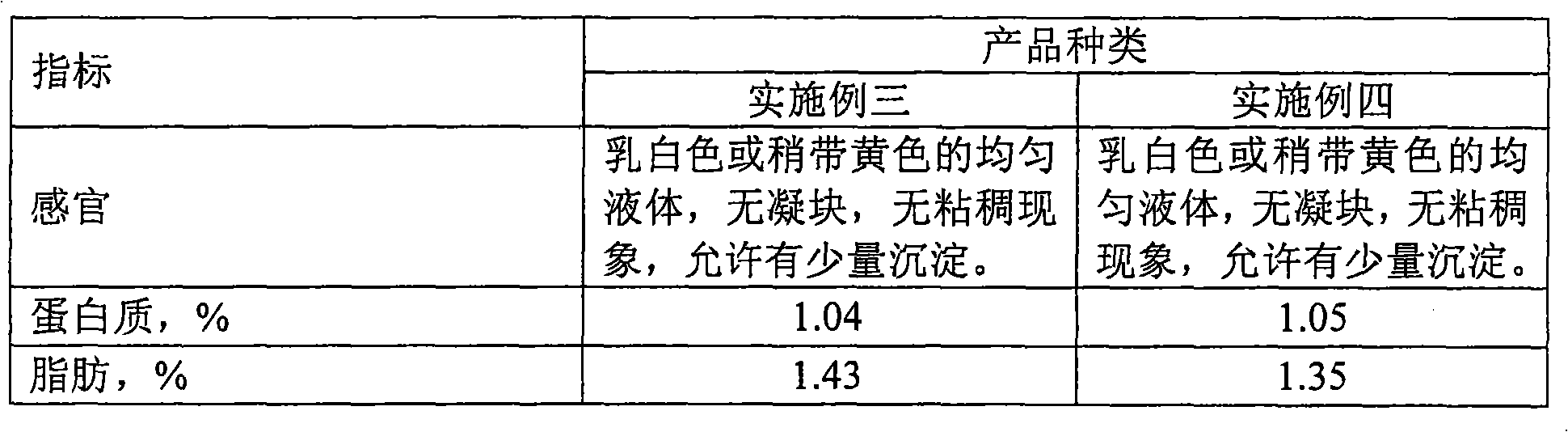

Embodiment 3

[0070] Embodiment 3, the neutral milk beverage containing lutein ester and zeaxanthin and its production method:

[0071] The raw material formula of the neutral milk drink of the present embodiment is (weight percentage composition):

[0072] milk 35.0

[0073] White sugar 8.50

[0074] Lutein ester + zeaxanthin raw material 0.04

[0075] Vitamin E 0.001

[0076] Single and double glycerides 0.040

[0077] Propylene glycol alginate 0.050

[0078] Sodium stearoyl lactylate 0.018

[0079] Sodium caseinate 0.008

[0080] Carrageenan 0.011

[0081] Complex nutrients 0.040

[0082] FOS 0.150

[0083] Inulin 0.250

[0084] Casein phosphopeptide 0.0030

[0085] Food flavor 0.080

[0086] water balance.

[0087] The production method of the neutral milk drink of lutein ester and zeaxanthin of the present embodiment is basically the same as that of embodiment 1, wherein compound nutrients, fructooligosaccharides, inulin, and casein phosphopeptide are added in the batching s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com