Curable composition for color filter, method for producing curable composition for color filter, colored curable resin composition, method for forming colored pattern, colored pattern, method for prod

A curable composition and compound technology, applied in the direction of optical filters, optical elements, nonlinear optics, etc., to achieve the effect of good pattern formation and superior process suitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

[0372]

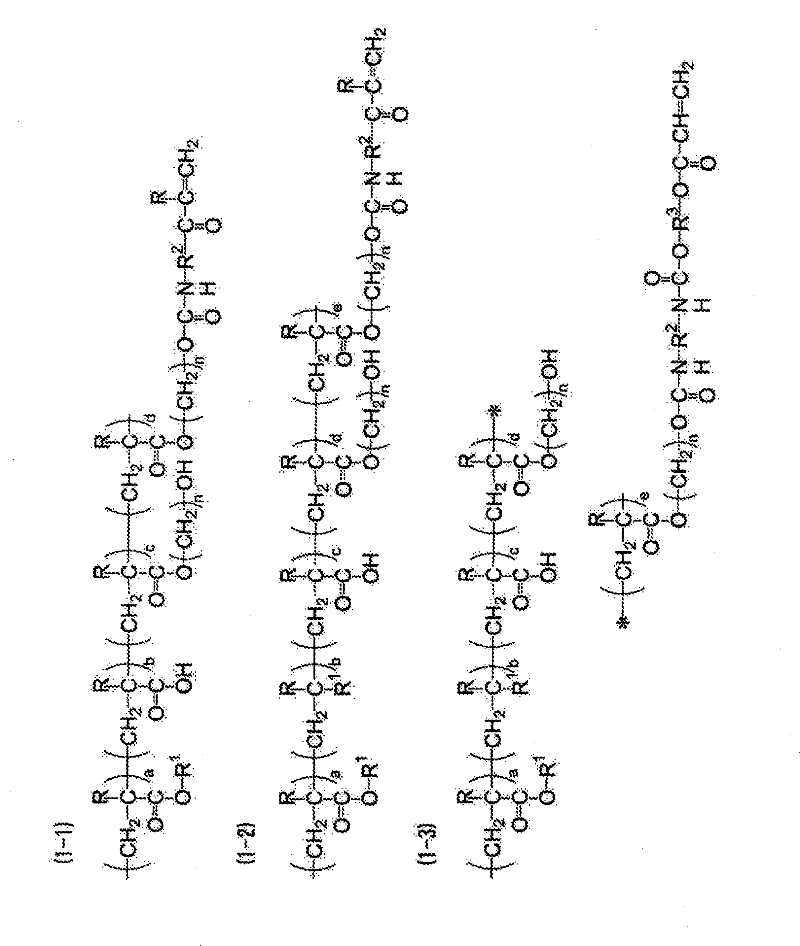

[0373] The colored curable resin composition of the second embodiment is characterized in that it contains: (a) a color material, (b) a compound having at least one ethylenically unsaturated double bond, (c) a compound having an alicyclic formula in the side chain The binder resin of (meth)acrylic acid copolymer of (meth)acryloyl group, (d) photopolymerization initiator, and (e) has at least one ethylenically unsaturated double bond, has in the molecule selected from urethane , amides, and partial structures of urea.

[0374] In addition to the above-mentioned essential components, other optional components may be added to the colored curable resin composition.

[0375] The concentration of the total solid content in the colored curable resin composition and the total colored curable resin composition is preferably 2 to 50% by mass, more preferably 10 to 30% by mass, and particularly preferably 15 to 25% by mass. .

[0376] Hereinafter, the constituent components ...

Embodiment 1

[0776] [1. Preparation of colored curable composition A-1]

[0777] 1-1. Preparation of pigment dispersion (P1)

[0778] 40 parts by mass of a 30 / 70 (mass ratio) mixture of C.I. Pigment Green 36 and C.I. Pigment Yellow 219 as a pigment, BYK 2001 (Disperbyk: manufactured by BYK) as a dispersant, solid content concentration 45.1 % by mass) 10 parts by mass (about 4.51 parts by mass in terms of solid content) and 150 parts by mass of ethyl 3-ethoxypropionate as a solvent were mixed and dispersed for 15 hours using a bead mill to prepare a pigment dispersion (P1).

[0779] As a result of measuring the average particle diameter of the pigment by the dynamic light scattering method about the obtained pigment dispersion liquid (P1), it was 200 nm.

[0780] 1-2. Preparation of colored curable composition A-1 (coating liquid)

[0781] The components of the following composition A-1 were mixed and dissolved to prepare colored curable composition A-1.

[0782]

[0783] ·Pigment dis...

Embodiment 2~6、 comparative example 1、2

[0832] In Example 1, the composition in the composition A-1 used in the preparation of the colored curable composition A-1 was replaced with the substances shown in the following Table 1, and it was the same as in Example 1 except that , Colored curable compositions A-2 to A-8 were prepared, and a color filter having a colored pattern using the same was obtained. Furthermore, the same evaluation as in Example 1 was performed. The results are shown in Table 1.

[0833] [Table 1]

[0834]

[0835] (3) Components shown in Table 1, that is, M-1 to M-6 are compounds synthesized as follows.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com