Method for refining metal silicon

A metal silicon, refined technology, applied in the direction of non-metallic elements, chemical instruments and methods, silicon compounds, etc., can solve the problems of large environmental pollution, high heating temperature, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

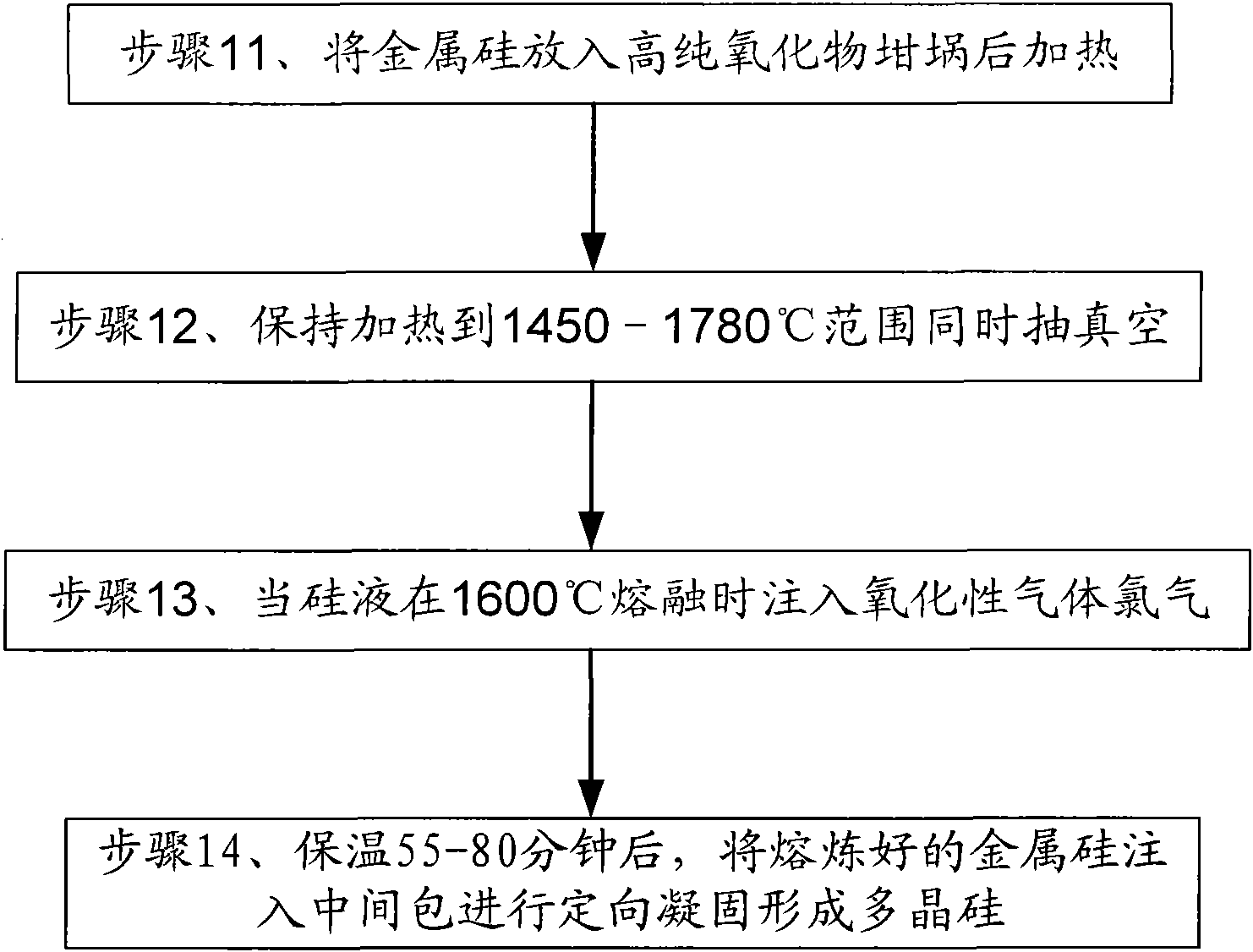

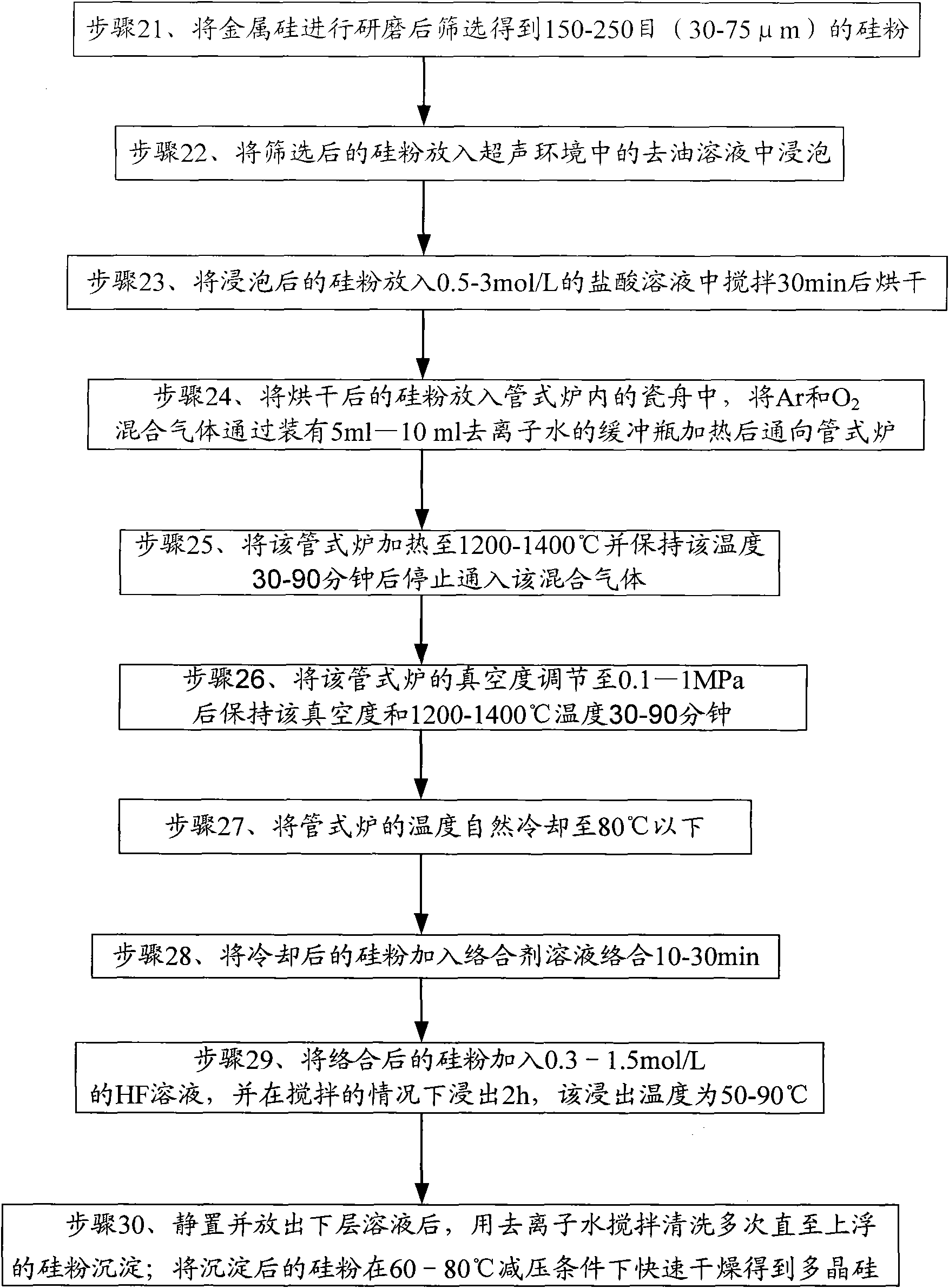

Method used

Image

Examples

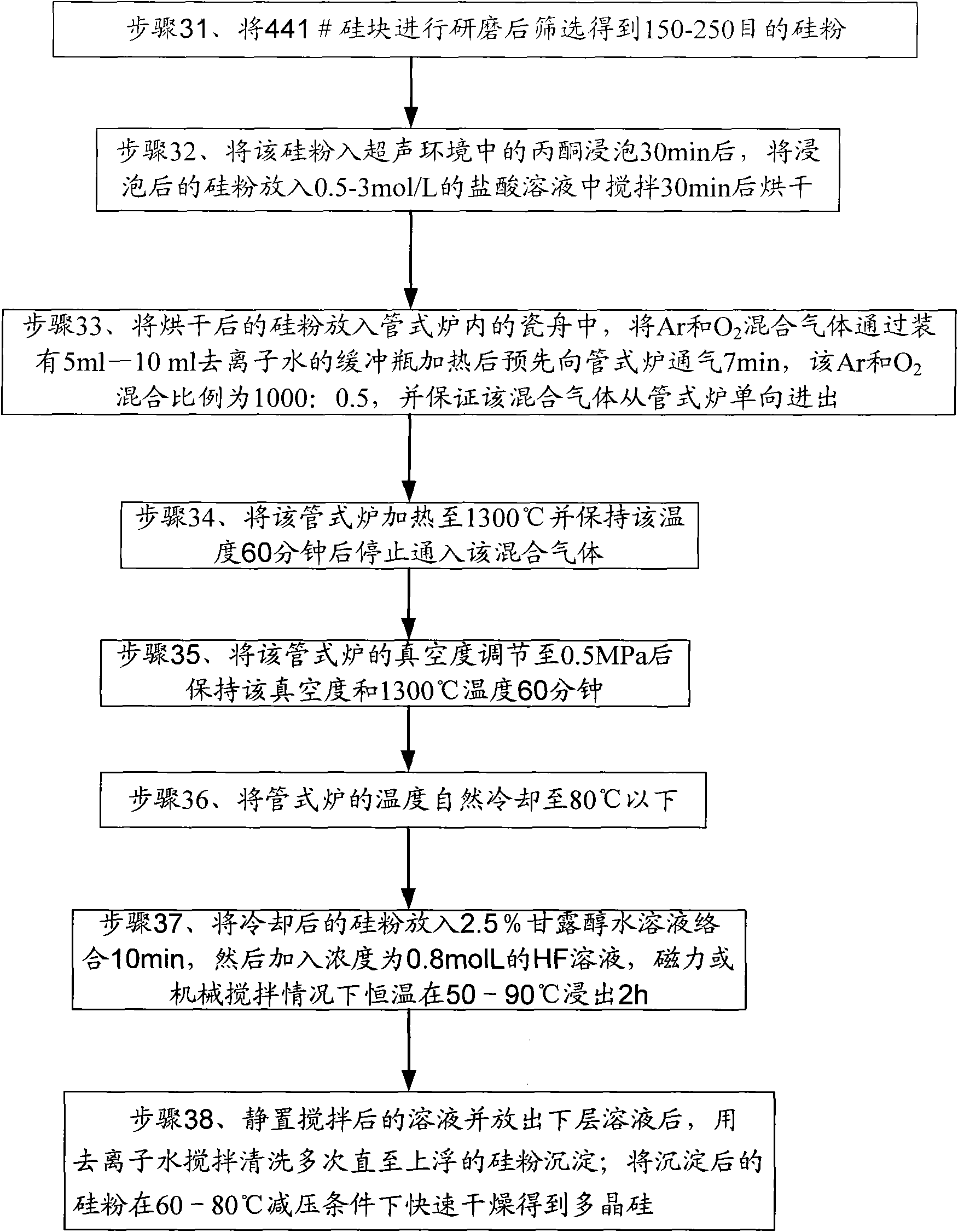

Embodiment 1

[0033] Embodiment 1: The specific embodiment 1 of the present invention provides a refining method for metal silicon. The technical scenario of this embodiment is that the metal silicon used in this embodiment is 441# silicon block. Of course, it can also be selected according to the actual situation Silicon blocks of different types; the degreasing solution selected in this embodiment is acetone, and the complexing agent solution selected is 2.5% mannitol water. The method as image 3 Shown: includes:

[0034] Step 31, grind the 441# silicon block and screen to obtain silicon powder of 150-250 mesh (30-75 μm);

[0035] The method for realizing this step can be as follows: crush the silicon block with a jaw crusher or use a hammer to break it into small pieces of 10-40mm, put it into an agate ball mill for dry grinding; put the silicon powder directly into a ball mill for ball milling. 20-30 large ball milling beads and 30-50 small ball milling beads are used for ball millin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com