Structural steel for bridge and method for manufacturing same

A manufacturing method and technology for structural steel, applied in the field of metallurgy, can solve the problems of high energy consumption in the production process, low impact toughness at low temperature, reduced steel toughness, etc., and achieve the effects of economical design, good corrosion resistance, and good weldability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

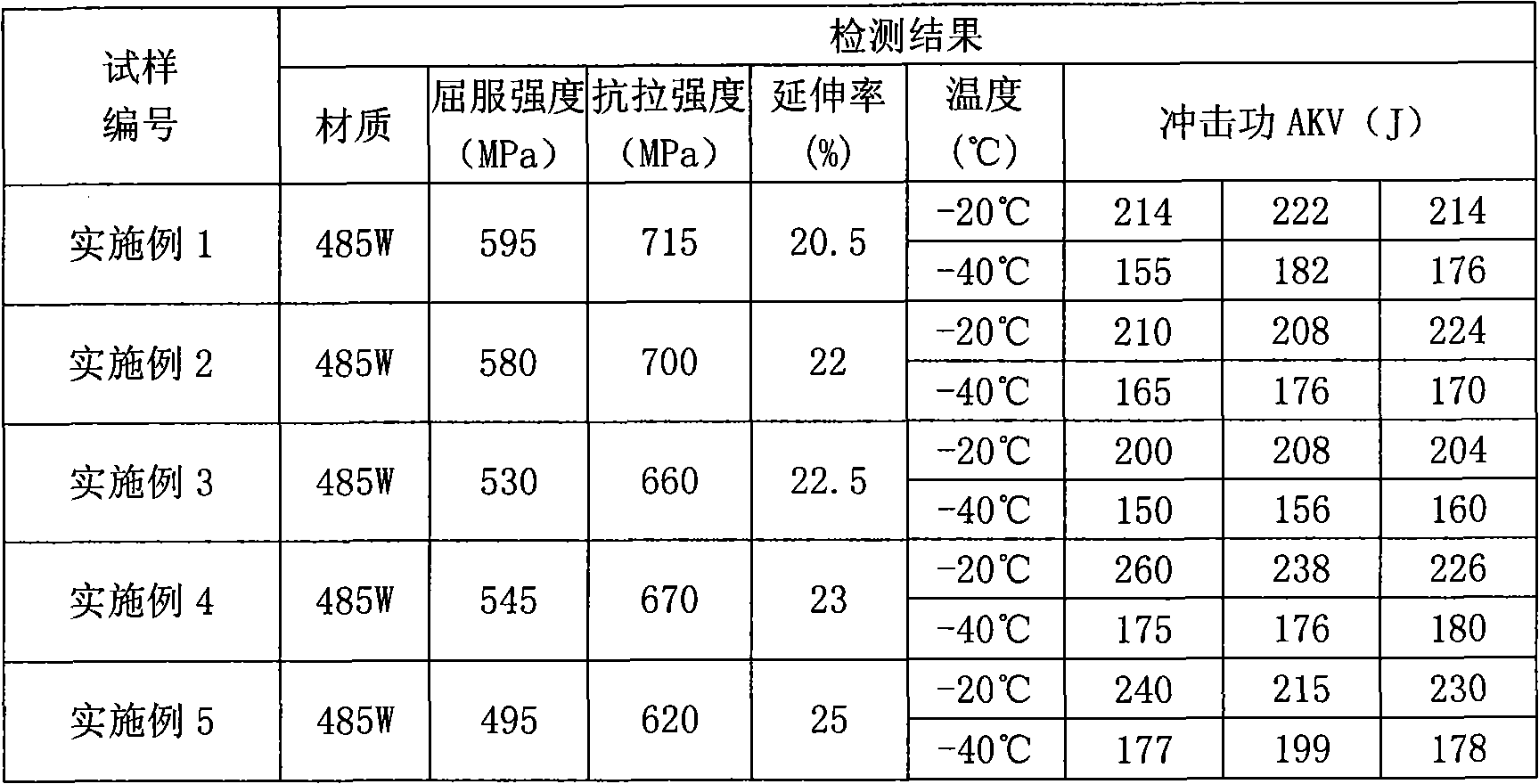

Examples

specific Embodiment approach

[0031] The main feature of the composition of the present invention is that the content of C is relatively low, and precious elements such as Nb and Ti are not added, and the content of its specific chemical composition is as follows (by weight): C0. %, Mn1.20%~1.35%, Cu0.30%~0.45%, Ni0.20%~0.35%, Cr0.30%~0.55%, Mo0.04%~0.07%, V0.02%~0.07%, Al0.02%~0.045%, the rest is Fe and unavoidable impurities.

[0032] The production process of the invention is: converter smelting→LF / VD refining→continuous casting→slab heating→rolling→laminar cooling→stacking and slow cooling→flaw detection→inspection and testing→storage.

[0033] Technological characteristics of the present invention are:

[0034] Steelmaking process: Converter smelting, deep decarburization through top blowing or top-bottom composite blowing, RH or VD vacuum furnace treatment and LF treatment to reduce the harmful effects of harmful gases O, H, N, etc. and S; Micro-alloying, adding iron vanadium before tapping, the am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com