Method for preparing lithium carbonate by using high boric bittern saturated solution

A lithium carbonate solution technology, applied in the field of salt chemical industry, can solve the problems of high production cost, difficult production process, large equipment investment, etc., and achieve the effect of small equipment investment, high recovery rate, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

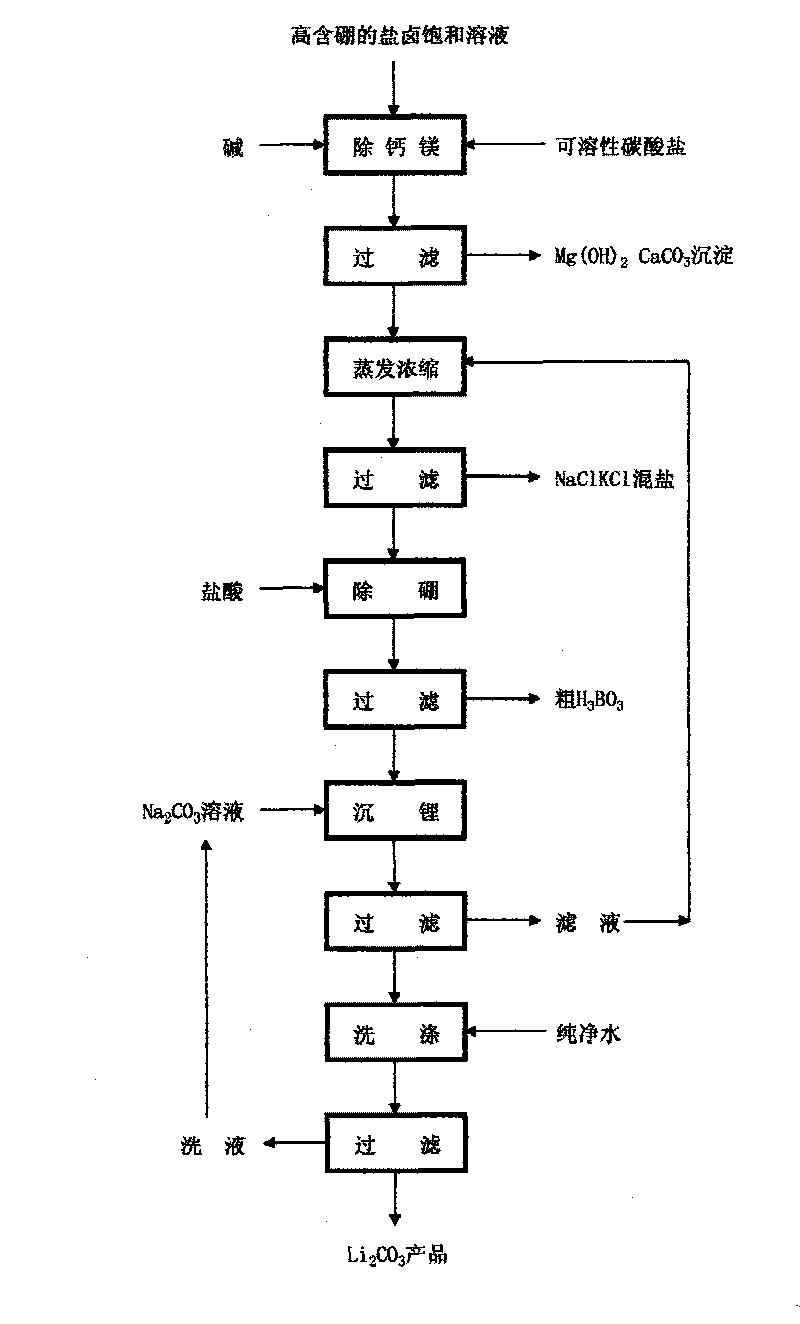

Method used

Image

Examples

Embodiment 1

[0019] Add appropriate amount of Ca(OH) to the saturated brine solution with high boron content 2 And Na 2 CO 3 , Make a small amount of magnesium and calcium in the solution form Mg(OH) respectively 2 , CaCO 3 Precipitation, solid-liquid separation to remove the precipitate. The solution after the removal of calcium and magnesium is concentrated by evaporation until the Li content is about 15g / L, a large amount of potassium chloride and sodium chloride mixed salt is precipitated, and potassium and sodium mixed salt are separated. Hydrochloric acid is added to the solution after separation of the potassium and sodium mixed salt to adjust the pH of the solution to 5-6. The boron in the solution is precipitated in the form of boric acid and borate, and the boric acid and borate are removed by solid-liquid separation. The boron-containing lithium solution is heated to 90° C., the lithium is precipitated with the sodium carbonate hot solution, and the solid-liquid separation is used...

Embodiment 2

[0021] Add appropriate amount of NaOH and K to the saturated brine solution with high boron content 2 CO 3 , Make a small amount of magnesium and calcium in the solution form Mg(OH) respectively 2 , CaCO 3 Precipitation, solid-liquid separation to remove the precipitate. After removing calcium and magnesium, the solution is evaporated and concentrated to a Li content of 9g / L, a large amount of potassium chloride and sodium chloride mixed salt is precipitated, and the potassium and sodium mixed salt is separated. Add hydrochloric acid to the solution after separating the potassium and sodium mixed salt to adjust the pH of the solution to 2 to 3. The boron in the solution is precipitated as boric acid, and the boric acid is removed by solid-liquid separation. The boron-containing lithium solution is heated to 60° C., the lithium is precipitated with the sodium carbonate hot solution, and the solid-liquid separation is used to obtain crude lithium carbonate. The obtained filtrate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com