Method for preparing poly(VDF-CTFE-TrFE) or poly(VDF-TrFE) by using poly(VDF-CTFE)

A technology of chlorotrifluoroethylene and vinylidene fluoride, which is applied in the hydrogenation of polymers and the preparation of polyP or polyP from polyP, which can solve the problems of environmental hazards for operators and the high toxicity of tributyltin chloride. Achieve the effect of being friendly to the human body and the environment, low cost, easy to operate and easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

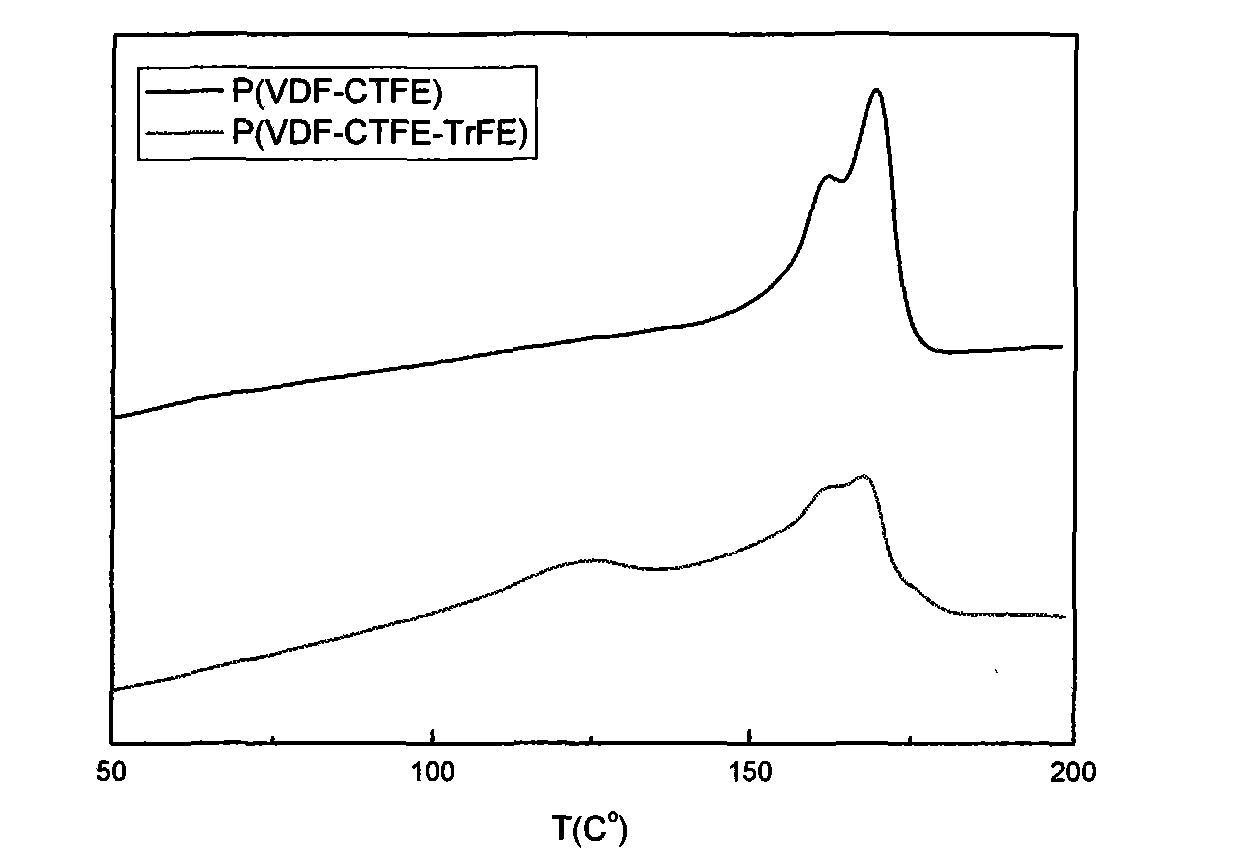

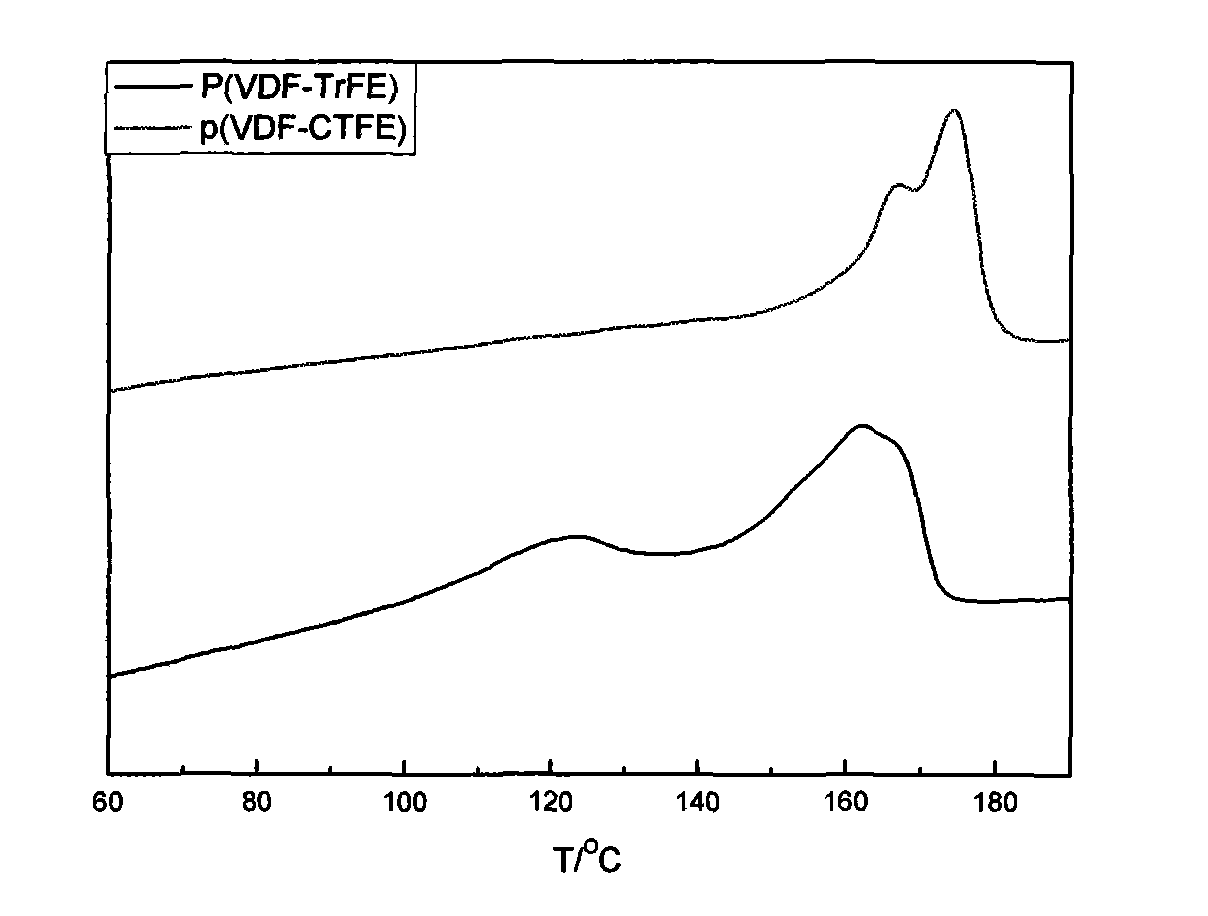

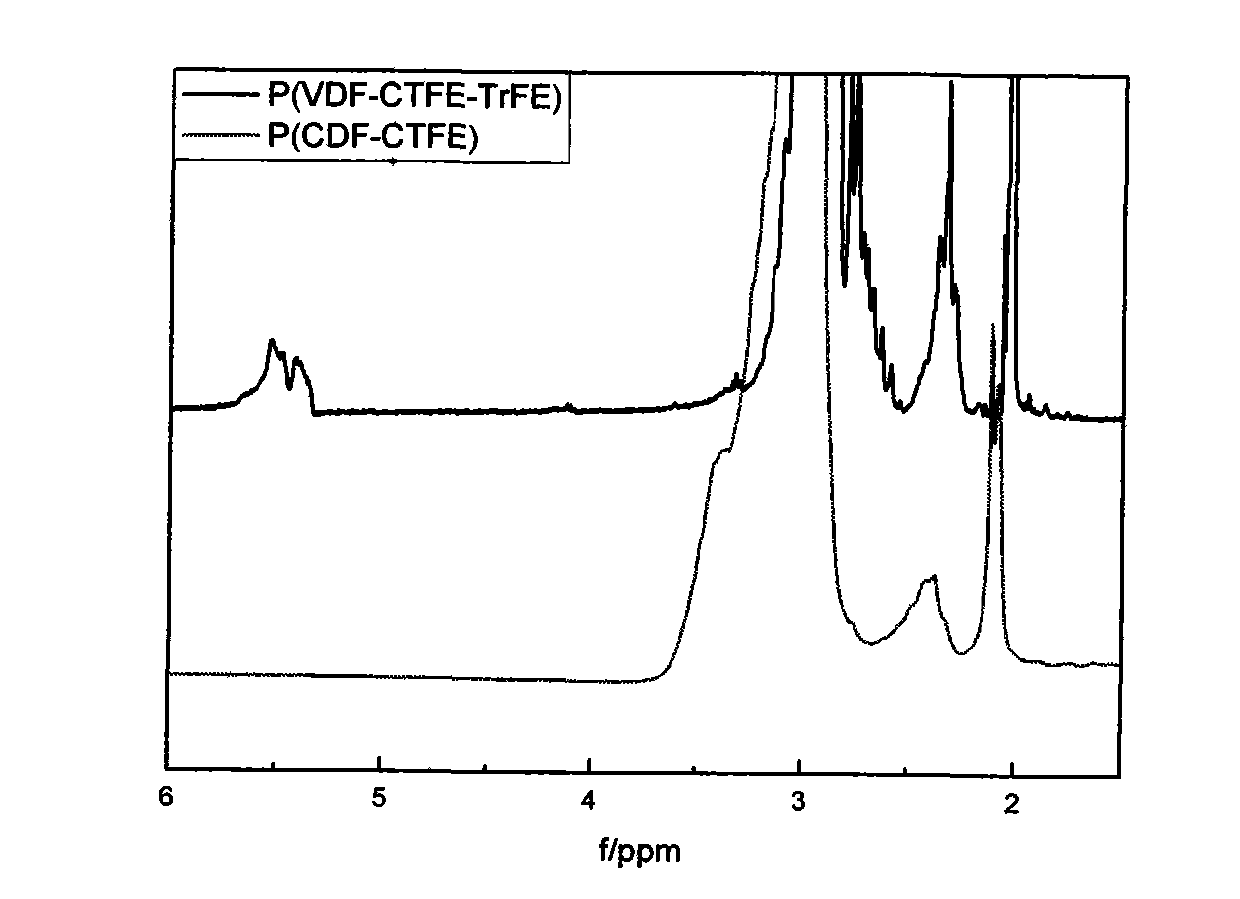

Method used

Image

Examples

Embodiment 1

[0061] The method of the present embodiment comprises the following steps:

[0062] 1. In an anhydrous and oxygen-free three-necked bottle, according to the mass ratio, add 2 parts of raw material poly(vinylidene fluoride-chlorotrifluoroethylene) P(VDF-CTFE), and at the same time add 80 parts of deoxidized N- Methylpyrrolidone, after being fully dissolved, add 0.32 parts of metal halide cuprous chloride CuCl, after the cuprous chloride CuCl is dissolved, in nitrogen N 2 Under protection, add 2-2'bipyridyl which is 2 times the molar number of the metal halide and cumene which is 7 times the molar amount of cuprous chloride CuCl, and react with constant magnetic stirring at a temperature of 100°C for 12 hours;

[0063] 2. Pour the final solution obtained in step 1 into a beaker with methanol and water. The ratio of methanol to water is arbitrary. The ratio of the total volume of methanol and water in the beaker to the volume of the solution in step 1 is 2:1 , after stirring for...

Embodiment 2

[0066] The method of the present embodiment comprises the following steps:

[0067] 1. In an anhydrous and oxygen-free three-necked bottle, according to the mass ratio, add 2 parts of raw material poly(vinylidene fluoride-chlorotrifluoroethylene) P(VDF-CTFE), and at the same time add 80 parts of deoxidized N- Methylpyrrolidone, after being fully dissolved, add 0.36 parts of cuprous chloride CuCl, after the cuprous chloride CuCl is dissolved, in nitrogen N 2 Under protection, add 2-2'bipyridyl which is 2 times the molar amount of cuprous chloride CuCl and cumene which is 7 times the molar amount of cuprous chloride CuCl, and react with constant magnetic stirring at 100°C for 12 hours;

[0068] 2. Pour the final solution obtained in step 1 into a beaker with methanol and water. The ratio of methanol to water is arbitrary. The ratio of the total volume of methanol and water in the beaker to the volume of the solution in step 1 is 2:1 , after stirring for 2 hours, the polymer pre...

Embodiment 3

[0071] The method of the present embodiment comprises the following steps:

[0072] 1. In an anhydrous and oxygen-free three-necked bottle, according to the mass ratio, add 1 part of raw material poly(vinylidene fluoride-chlorotrifluoroethylene) P(VDF-C TFE), and at the same time add 50 parts of deoxidized N -Methylpyrrolidone, after fully dissolving, add 0.24 parts of cuprous bromide CuBr, after cuprous bromide CuBr dissolves, in N 2 Under protection, 2-2' bipyridine with 2 times the molar amount of CuBr and cumene with 7 times molar amount of CuBr were added, and the reaction was carried out under constant magnetic stirring at 110°C for 12 hours.

[0073] 2. Pour the final solution obtained in step 1 into a beaker with methanol and water. The ratio of methanol to water is arbitrary. The ratio of the total volume of methanol and water in the beaker to the volume of the solution in step 1 is 2:1 , after stirring for 2 hours, the polymer precipitated out. The obtained polymer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com