Method for manufacturing high efficient two-sided N-shaped crystalline silicon solar cell based on silk-screen printing technique

A technology of screen printing and solar cells, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of complex process and high cost, and achieve the effect of simple manufacturing process, high production efficiency and high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

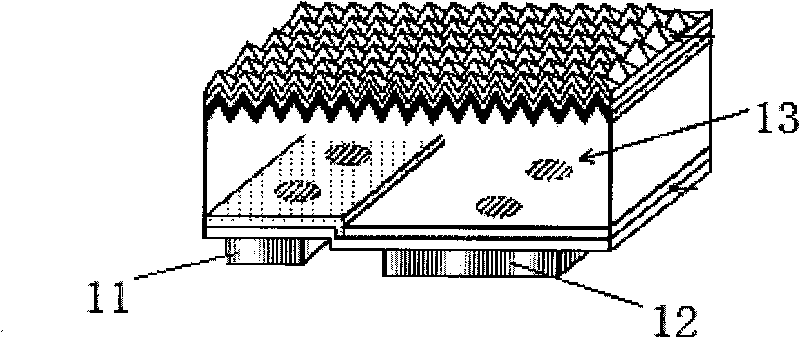

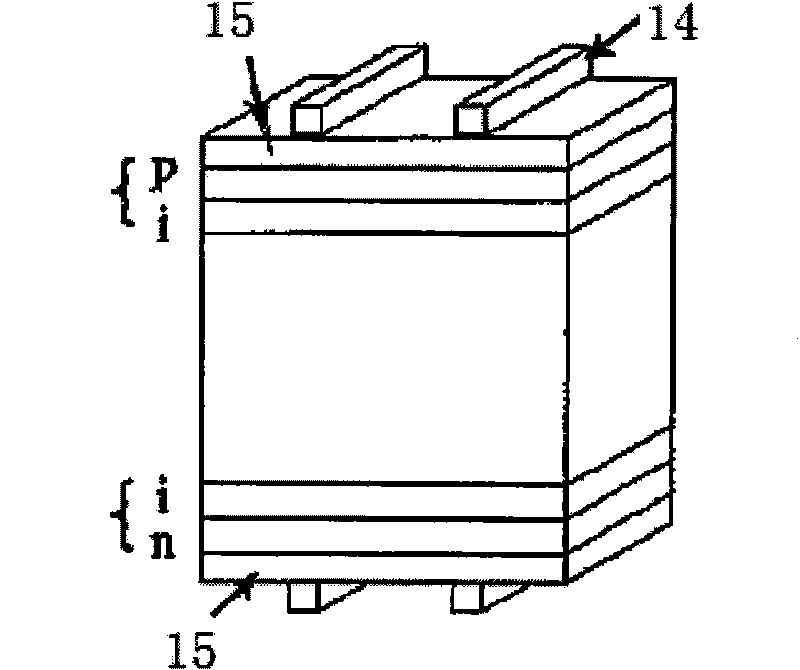

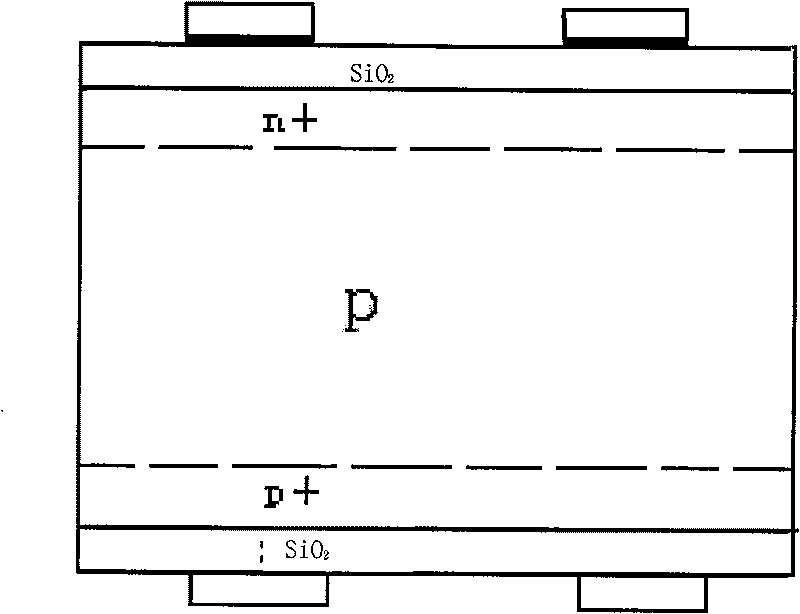

[0019] 1) Remove the damaged layer of the silicon wafer, make texture,

[0020] 2) Boron diffusion, remove the front and edge boron diffusion layer, grow the back diffusion barrier layer,

[0021] 3) Phosphorus diffusion, removal of barrier layer, growth of silicon oxide or aluminum oxide passivation layer on the back, deposition of silicon nitride anti-reflection layer on both sides,

[0022] 4) Sintering of printed front and back electrodes.

Embodiment 2

[0024] 1) Remove the damaged layer of the silicon wafer, make texture, and grow the front diffusion barrier layer,

[0025] 2) Boron diffusion, removal of the barrier layer, growth of the back diffusion barrier layer,

[0026] 3) Phosphorus diffusion, removal of barrier layer, growth of silicon oxide or aluminum oxide passivation layer on the back, deposition of silicon nitride anti-reflection layer on both sides,

[0027] 4) Sintering of printed front and back electrodes.

Embodiment 3

[0029] 1) Remove the damaged layer of the silicon wafer, make texture,

[0030] 2) Phosphorus diffusion, remove the back and edge phosphorus diffusion layer, grow the front diffusion barrier layer,

[0031] 3) Boron diffusion, removal of barrier layer, growth of silicon oxide or aluminum oxide passivation layer on the back, deposition of silicon nitride anti-reflection layer on both sides,

[0032] 4) Sintering of printed front and back electrodes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com