Novel loaded transition metal composite membrane and preparation method thereof

A transition metal and transition metal ion technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as difficult industrialization and chemical instability, and achieve the effect of easy operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

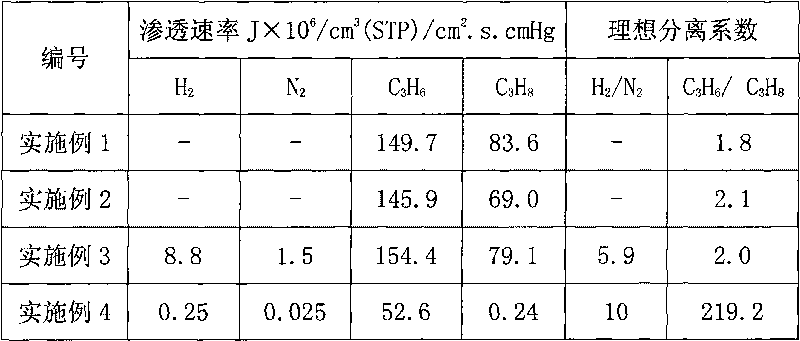

Embodiment 1

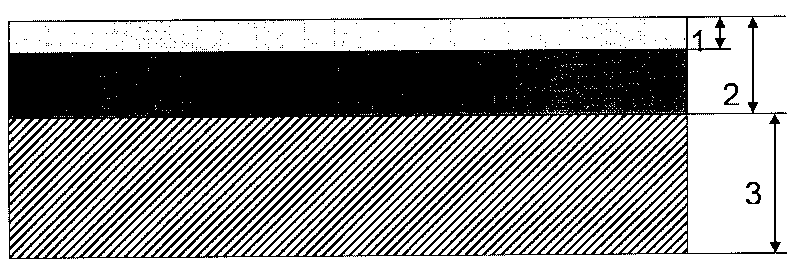

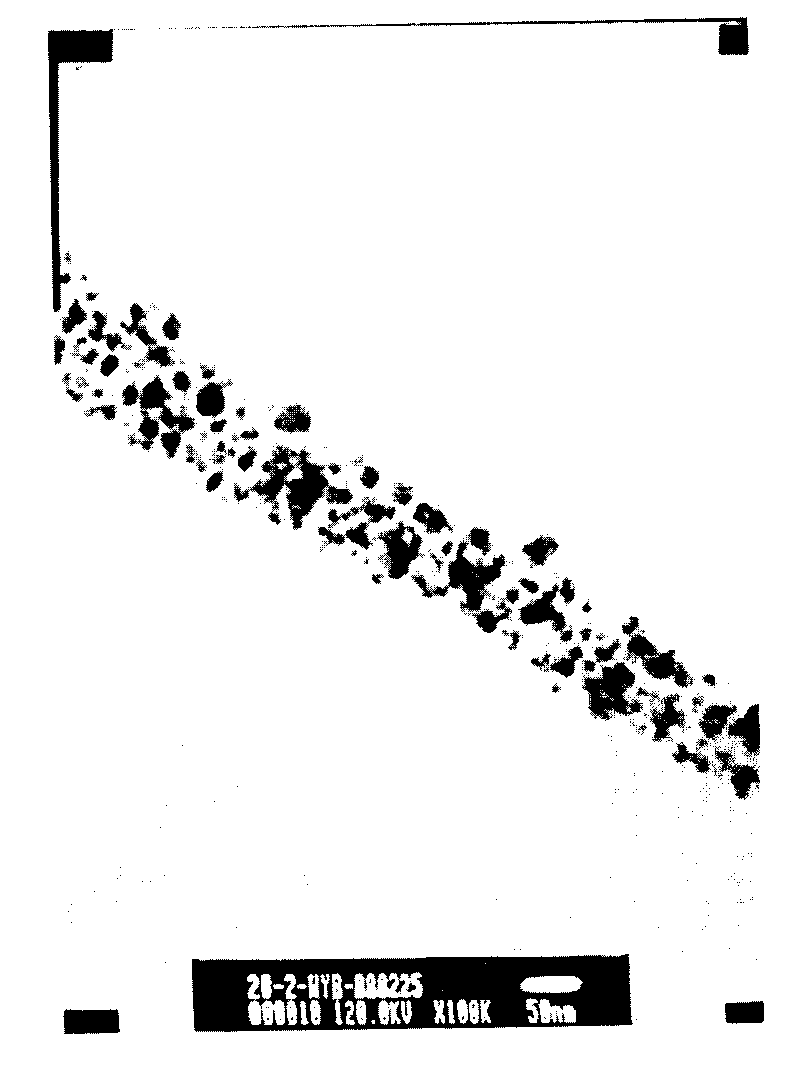

[0022] On the support membrane 1 porous polyetherimide ultrafiltration membrane, the mass concentration of 6% PEBA2533 was coated by dip coating method, the solvent was butanol, the coating temperature was 50 ° C, and the drying time was 4 hours. The prepared composite membrane was vacuum-coated. Dry in an oven at 30° C. for 24 h to remove the remaining solvent to form a separation layer 2 . Then using the one-sided ligand solution exchange method, with 1.0M AgNO 3 The solution introduces transition metal ions into the separation layer of the composite membrane on one side, pours out the transition metal soluble salt solution after 2 hours, rinses the surface with deionized water, and puts it in the dark for 24 hours. The surface of the separation layer has a transition metal infiltration layer. 3. Then conduct a gas permeation test.

Embodiment 2

[0024] On the support membrane porous polyetherimide ultrafiltration membrane, use the dipping coating method to coat the mass concentration of 6%PEBA2533, the solvent is butanol, the coating temperature is 50°C, and the drying time is 4h. The prepared composite membrane is dried in a vacuum oven. Dry at 30° C. for 24 h to remove the remaining solvent to form the separation layer 2 . Using the one-sided ligand solution exchange method, with 5.0M AgNO 3 The solution introduces transition metal ions into the separation layer of the composite membrane on one side, pours out the transition metal soluble salt solution after 2 hours, rinses the surface with deionized water, and puts it in the dark for 24 hours. The surface of the separation layer has a transition metal infiltration layer. 3. Then conduct a gas permeation test.

Embodiment 3

[0026] 6% PEBA2533 was coated on the support membrane porous polyetherimide ultrafiltration membrane by dip coating method, the solvent was butanol, the coating temperature was 50° C., and the drying time was 4 hours. The prepared composite membrane was dried in a vacuum oven at 30° C. for 24 hours to remove the remaining solvent to form the separation layer 2 . Using the one-sided ligand solution exchange method, use 1.0M AgBF 4The solution introduces transition metal ions into the separation layer of the composite membrane on one side, pours out the transition metal soluble salt solution after 2 hours, rinses the surface with deionized water, and puts it in the dark for 24 hours. The surface of the separation layer has a transition metal infiltration layer. 3. Then conduct a gas permeation test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com