Polyurethane resin with intelligent moisture permeating function for synthetic leather surface coating and preparation method thereof

A polyurethane resin and surface coating technology, applied in the field of polyurethane resin, can solve the problems of low strength, low price, high price, etc., and achieve the effect of good moisture permeability and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 60g of polyethylene glycol with a number-average molecular mass of 6000 and 20g of polyethylene adipate with a number-average molecular mass of 2000 into a 1000mL three-necked flask with a stirrer, raise the temperature to 110°C, and start Stir and dehydrate under vacuum for 3 hours, then cool to 60°C, blow in nitrogen to release the vacuum, add 40g of dimethylformamide, and stir evenly. Then add 5g of 4,4'-diphenylmethane diisocyanate, react at 60°C for 4h, and add 80g of dimethylformamide according to the viscosity of the reactant. After the prepolymerization was completed, 4.5g of 1,4-butanediol and 12.5g of 4,4'-diphenylmethane diisocyanate were added successively, and after reacting for 3 hours at 70°C, 118g of dimethylformamide was added to obtain a solid content of 30% polyurethane solution.

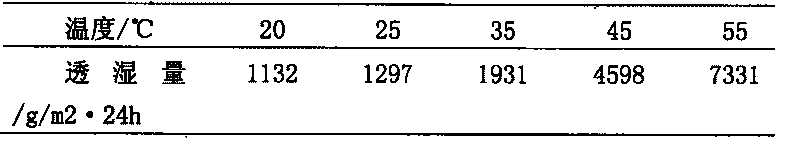

[0023] The obtained polyurethane solution was coated on the synthetic leather base, and the moisture permeability at various temperatures was tested as shown in Table ...

Embodiment 2

[0027] Add 60g of polyethylene glycol with a number-average molecular mass of 6000 and 20g of polybutylene adipate with a number-average molecular mass of 2000 into a 1000mL three-necked flask with a stirrer, raise the temperature to 110°C, and start Stir and dehydrate under vacuum for 3 hours, then cool to 80°C, blow in nitrogen to release the vacuum, add 30g of dimethylacetamide, and stir well. Then add 5g of 4,4'-diphenylmethane diisocyanate, react at 80°C for 2h, and add 100g of dimethylacetamide according to the viscosity of the reactant. After the prepolymerization was completed, 4.9g of 1,4-butanediol and 13.5g of 4,4'-diphenylmethane diisocyanate were added successively, and after reacting for 2 hours at 80°C, 62g of dimethylacetamide was added to obtain a solid content of 35% polyurethane solution.

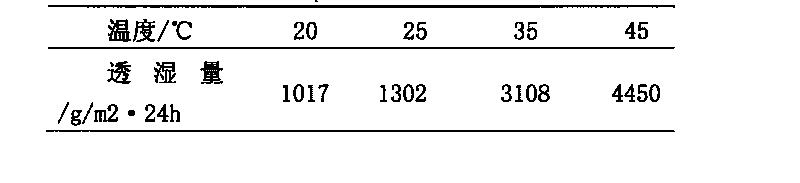

[0028] The obtained polyurethane solution was coated on the synthetic leather base, and the moisture permeability at various temperatures was tested as shown in Table 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com