Method for preparing carbonyl iron powder in high-pressure circulating way

A technology of carbonyl iron powder and high-pressure circulation, which is applied in the direction of carbonyl iron, etc., can solve the problems of slow gas-solid phase fresh surface contact change, pentacarbonyl iron cannot be discharged in time, and carbonyl iron carries a lot of liquid, so as to improve labor intensity and increase Product added value, effect of increasing carbonylation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

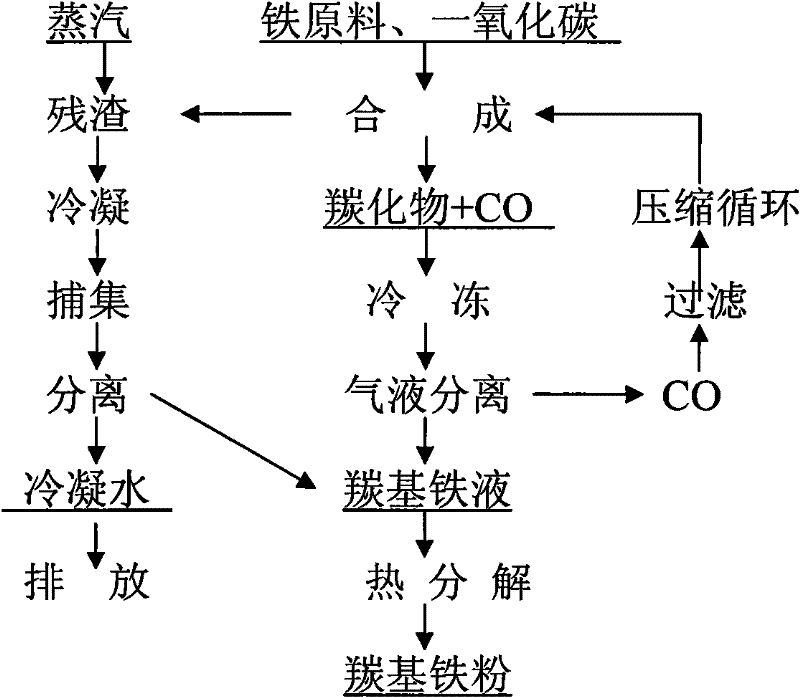

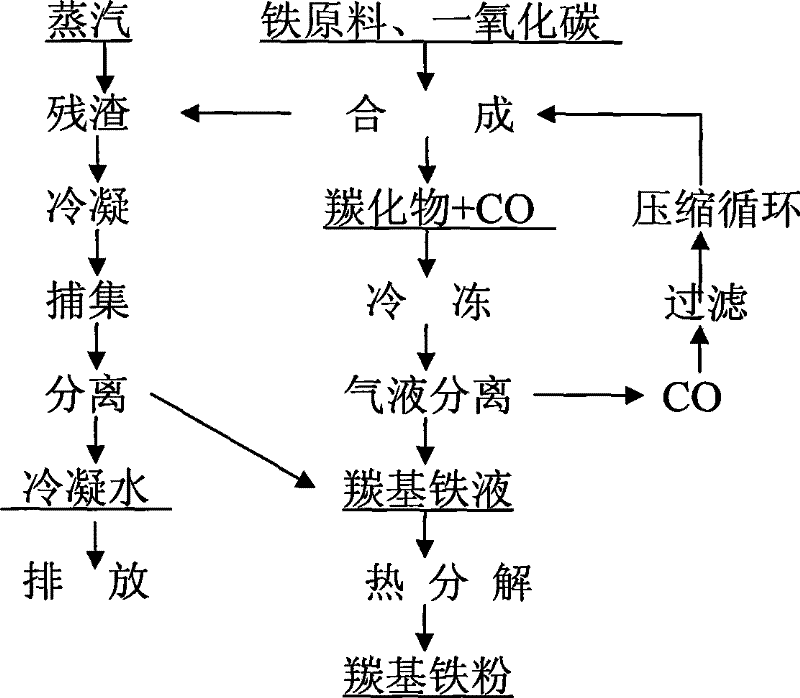

[0016] The porous sponge iron raw material and carbon monoxide are synthesized under the condition of 11.0-30.0MPa to produce iron pentacarbonyl. The frozen iron pentacarbonyl liquid is filtered and purified, and vaporized and thermally decomposed into micron-sized iron carbonyl in a thermal decomposer at a certain temperature. Powder; the reaction gas separated by freezing is cooled by a water chiller and finely filtered, and then sent to the circulating compressor, which is 0.1-0.4m 3 / min pressure to send the reaction gas into the synthesis kettle.

[0017] The above carbon monoxide gas high-pressure cycle synthesis technology is to purify and separate the unreacted gas under high pressure, and then pressurize and return it to the synthesis kettle to participate in the synthesis reaction. The high-pressure gas circulation is based on the working conditions of the synthesis reaction stage. 3 It can be adjusted within the range of / min, and the synthesis effect of 20.0-25.0MP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com