Method for preparing hollow spherical ferroferric oxide nano material

A technology of ferric tetroxide and nanomaterials, which is applied in nanostructure manufacturing, iron oxide/ferric hydroxide, nanotechnology and other directions, can solve the problems of limiting the application research of magnetic hollow ferric tetroxide and the cumbersome preparation method, and achieves good results. Stable and reproducible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1. Preparation of hollow spherical ferric oxide nanomaterial

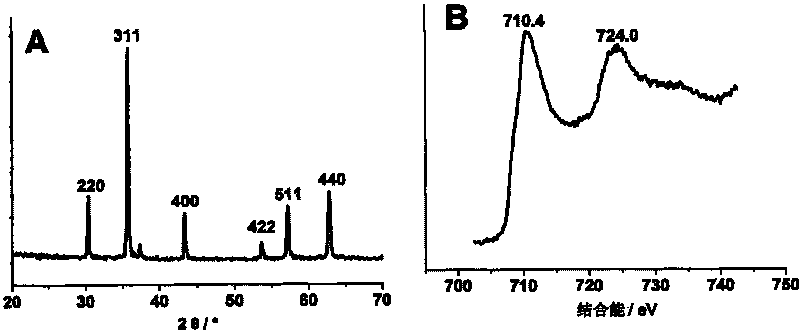

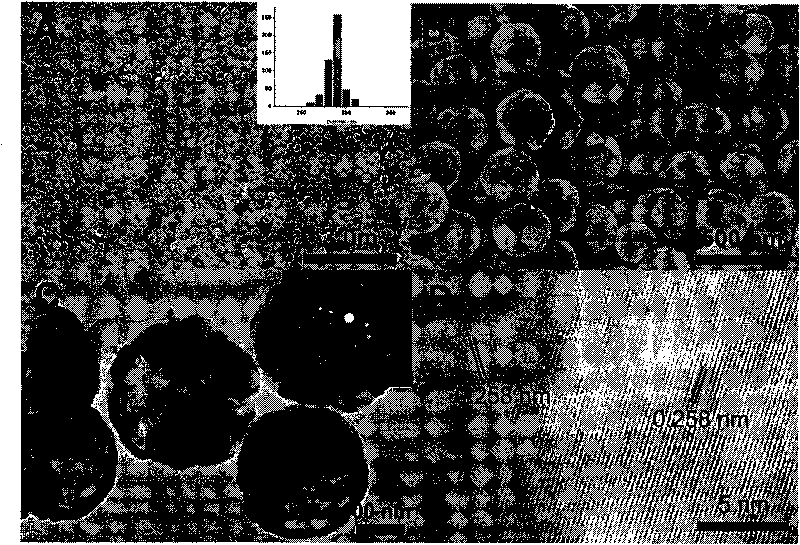

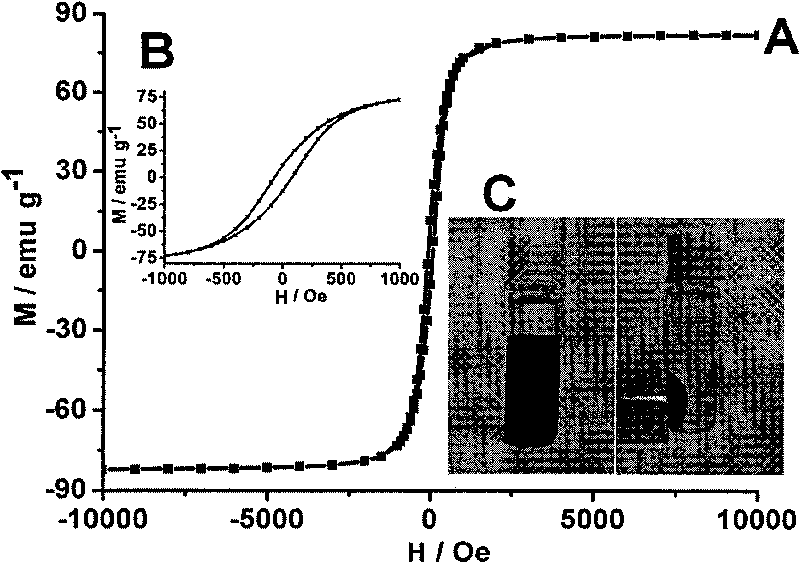

[0016] First weigh 20mmol of ferric chloride hexahydrate, dissolve it in 40ml of ethylene glycol, stir to obtain a uniform reddish-brown solution, add 40mmol of anhydrous sodium acetate to the solution, ultrasonicate and stir to obtain a uniform yellow-brown solution. Transfer the above solution to a hydrothermal kettle liner with a total volume of 50ml (made of polytetrafluoroethylene), cover the reaction kettle, react in a constant temperature oven at 200°C for ten hours, cool to room temperature naturally, take out the sample, wash with water, The product was obtained after washing several times with ethanol. Characterized by X-ray powder diffraction (XRD) and X-ray photoelectron spectroscopy (XPS), the results show that the prepared sample is ferric oxide (see figure 1 A and figure 1 B). Scanning electron microscope (SEM) and transmission electron microscope (TEM) characterize, the result s...

Embodiment 2

[0017] Embodiment 2. Preparation of hollow spherical ferric oxide nanomaterials

[0018] Change "40ml ethylene glycol" in Example 1 to "80ml diethylene glycol", and other preparation conditions are the same as in Example 1, to obtain a product similar to Example 1 in appearance and properties.

Embodiment 3

[0019] Embodiment 3. Preparation of hollow spherical ferric oxide nanomaterials

[0020] "20mmol ferric chloride hexahydrate" of embodiment 1 is changed into "10mmol ferric chloride hexahydrate", 40mmol anhydrous sodium acetate is changed into "20mmol anhydrous sodium acetate", and "40ml ethylene glycol" is changed into "20ml ethylene glycol". Diol", the other conditions of preparation are the same as in Example 1, and the product whose appearance and properties are similar to Example 1 is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com