Material prepared from purely natural material and used for wounds

A biomedical material and wound technology, applied in the field of medical devices, can solve the problems of skin and wound irritation, easy to produce allergic reactions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

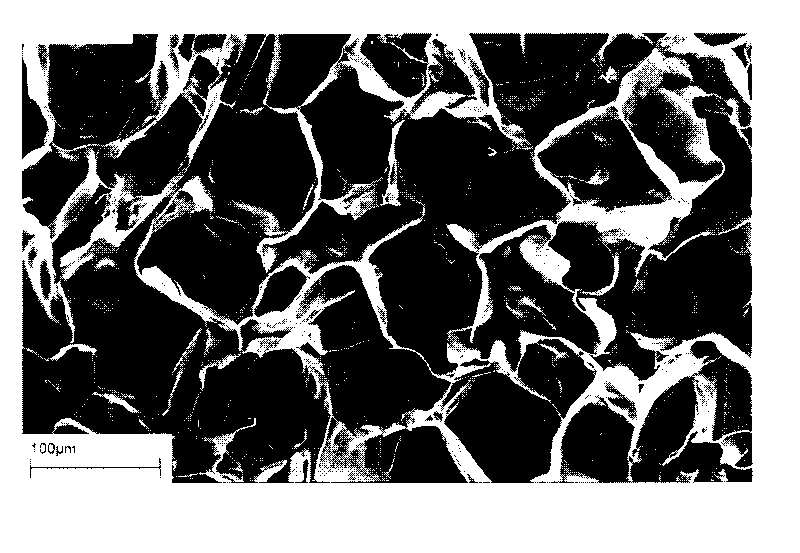

Image

Examples

Embodiment 1

[0037] Embodiment 1: Silk fibroin removes sericin

[0038] (1) Remove sericin. 20g Na 2 CO 3 Dissolve in 4L of water, heat to 100°C, add 75g silkworm reeled silk, keep the solution slightly boiling, and keep stirring. Pour off the solution after 1 hour, cool the boiled silk fibroin naturally, rinse it with deionized water, put it in an oven for 24 hours, and dry it at 50°C for later use.

[0039] (2). Dissolving silk fibroin. Take 44.4g CaCl 2 , 46mL ethanol, 57.6mL deionized water to make a mixed solution, put 15g dried silk fibroin in this solution. After fully immersing the silk fibroin in the solution, heat it in a water bath at 80°C and stir to dissolve it. After 1 hour, the silk fibroin is completely dissolved, stop heating and stirring, and naturally cool the silk fibroin solution to room temperature.

[0040] (3). Dialysis of silk fibroin solution. Pour the cooled silk fibroin solution into a dialysis bag (8000-10000Da), dialyze with tap water at room temperatu...

Embodiment 2

[0046] Embodiment 2 prepares absorbent pad or hemostatic sponge by silk fibroin and chitosan:

[0047] (1). Prepare 0.2M acetic acid solution. Dissolve 1.2 g of acetic acid in deionized water and titrate to 100 mL to obtain a 0.2 M acetic acid solution.

[0048] (2). Prepare 3% chitosan solution. Take 40mL of acetic acid solution and dissolve 1.2g of chitosan to obtain a light yellow viscous solution.

[0049](3). Prepare silk fibroin / chitosan mixed solution. Prepare a silk fibroin / chitosan mixed solution, the ratio of the two is 1:1, and stir for 15 minutes.

[0050] (4). Mold molding, freeze-drying. The silk fibroin / chitosan mixed solution was poured into different polytetrafluoroethylene molds, the samples were frozen at -20°C for 24h, and then freeze-dried for 48h (-54°C, 80Pa).

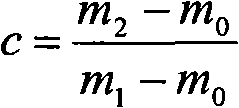

[0051] (5). Methanol treatment. The freeze-dried sample was taken out from the mold, soaked in methanol for 2-6 hours, poured off the methanol, and freeze-dried for 48 hours to remove resid...

Embodiment 3

[0053] Embodiment 3: Absorbent pad or hemostatic sponge prepared by silk fibroin and dextran.

[0054] (1). Prepare 1% silk fibroin solution. Take 0.4g silk fibroin and dissolve it in 40ml deionized water to obtain a viscous solution.

[0055] (2). Prepare 1% dextran solution. Take 40mL of deionized water and dissolve 0.4g of dextran to obtain a viscous solution.

[0056] (3). Prepare silk fibroin / dextran mixed solution. The above two solutions were mixed according to the volume ratio of 1:1, and stirred evenly.

[0057] (4). Freeze-dried molding. The silk fibroin / dextran solution was poured into the mold, and the mold containing the samples was frozen at -20°C for 24 hours, and then freeze-dried for 48 hours.

[0058] (5). Methanol treatment. The freeze-dried sample was taken out from the mold, soaked in methanol for 2-6 hours, poured off the methanol, and freeze-dried for 48 hours to remove residual methanol. Finally get the silk fibroin / glucan medical material we nee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com