Purification system of anhydrous hydrogen fluoride gas

An anhydrous hydrogen fluoride, purification system technology, applied in fluorine/hydrogen fluoride, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of difficult to control the production process, unsatisfactory purification effect, high price and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

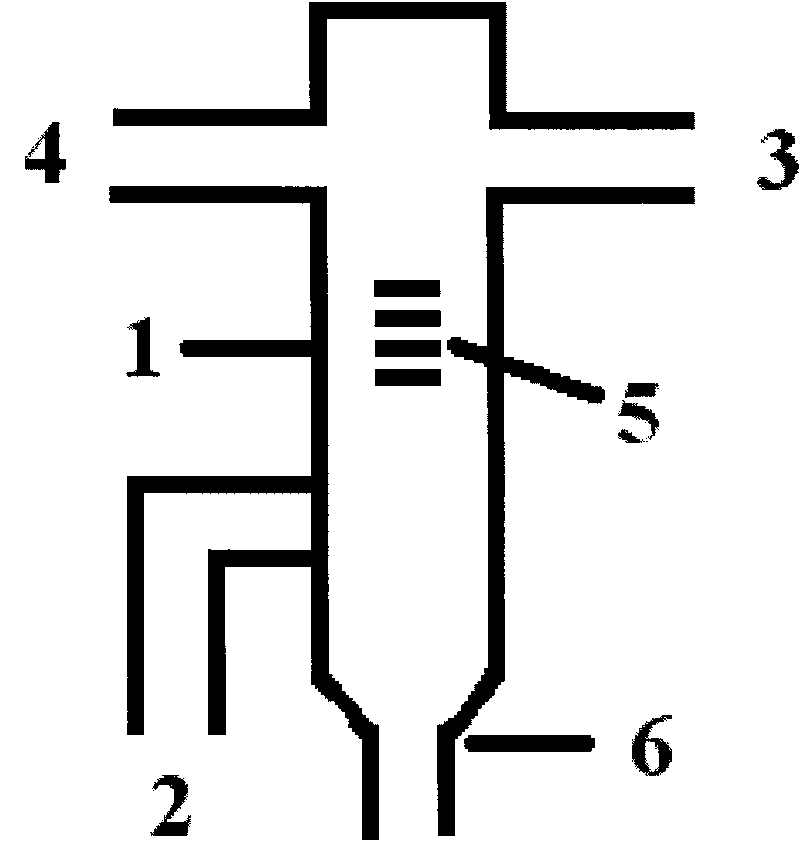

[0011] The purification system includes an air inlet pipe, an air outlet pipe, a purification tower, a dust collection device and a back blowing device. The inlet pipe is located in the lower half of the purification tower, and one end is connected to the purification tower through an elbow. When in use, the other end is connected to the reactor for preparing hydrogen fluoride gas; the outlet pipe is located in the upper half of the purification tower, and one end passes through the purification tower. When using, the other end is connected to the subsequent use system; a membrane material that can withstand temperature: 20-100°C and negative pressure: 1000-3000MPa is placed in the purification tower. At the same time, the membrane material is resistant to hydrofluoric acid corrosion. And its pore diameter is less than 1μm, and the specific surface area is greater than 180m 2 / g, preferably tetrafluoroethylene, polyvinylidene fluoride, polysulfone, polycarbonate, polyethersulfon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com