Preparation method of ultra-high maltose syrup

A maltose syrup and ultra-high technology, applied in the field of preparation of ultra-high maltose syrup, can solve problems such as low utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

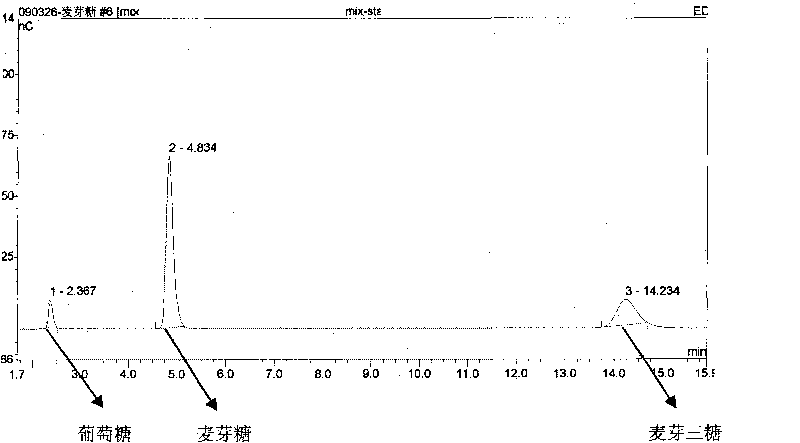

Image

Examples

Embodiment Construction

[0009] (1) Preparation of rice starch slurry

[0010] Take the broken rice (about 10% of the broken rice produced in the rice processing process) and wash it and soak it with lye to remove the soluble protein in the rice. The concentration of lye is 0.05-0.15mol / LNaOH, the ratio of solid to liquid is 1:6-8, the temperature is 45-50°C, soak for 2-3 hours. After soaking, rinse with water until the rice milk is neutral, and refine the pulp.

[0011] (2) Preparation of ultra-high maltose syrup

[0012] 1. Sizing: Add rice starch slurry to the batching kettle, add rice starch under stirring, the specific gravity of the slurry is 15°Bé, first use HCl and Na 2 CO 3 Slurry to pH5.6~5.8, then add CaCl 2 Stir well with high temperature resistant α-amylase, CaCl 2 The metering is added at 0.4g / kg, and the high temperature resistant α-amylase is metered at 0.15g / kg.

[0013] 2. Liquefaction: After the jet liquefaction equipment is fully preheated, the material is pumped into the jet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com