Composite guided wave structure formed by coupling metal nano lines, nano optical fiber and optical nano line

A technology of metal nanowires and nanofibers, applied in the direction of optical waveguide light guide, light guide, optics, etc., can solve the problems of unfavorable high-density integration, signal attenuation, heat generation, etc., and achieve easy control and adjustment, reduce device loss, and high coupling efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the purpose and effect of the present invention will become more obvious.

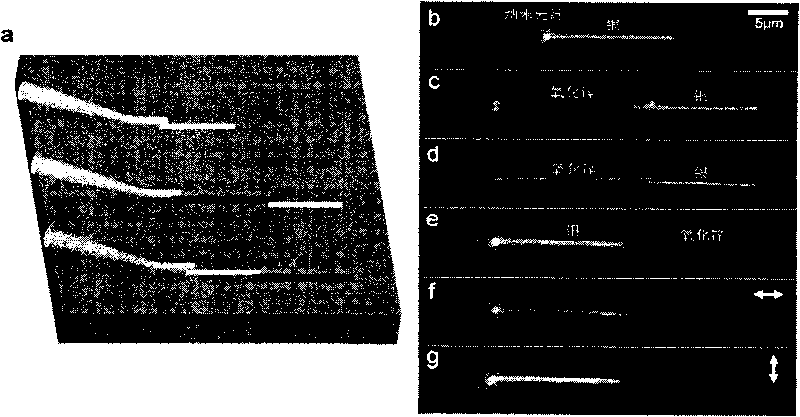

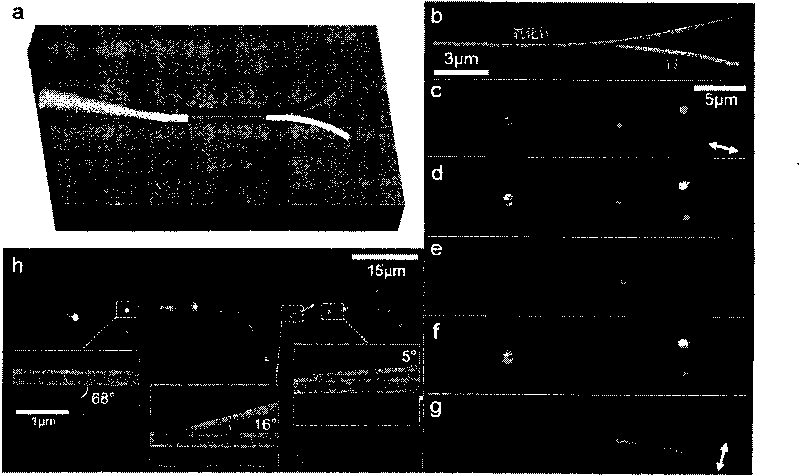

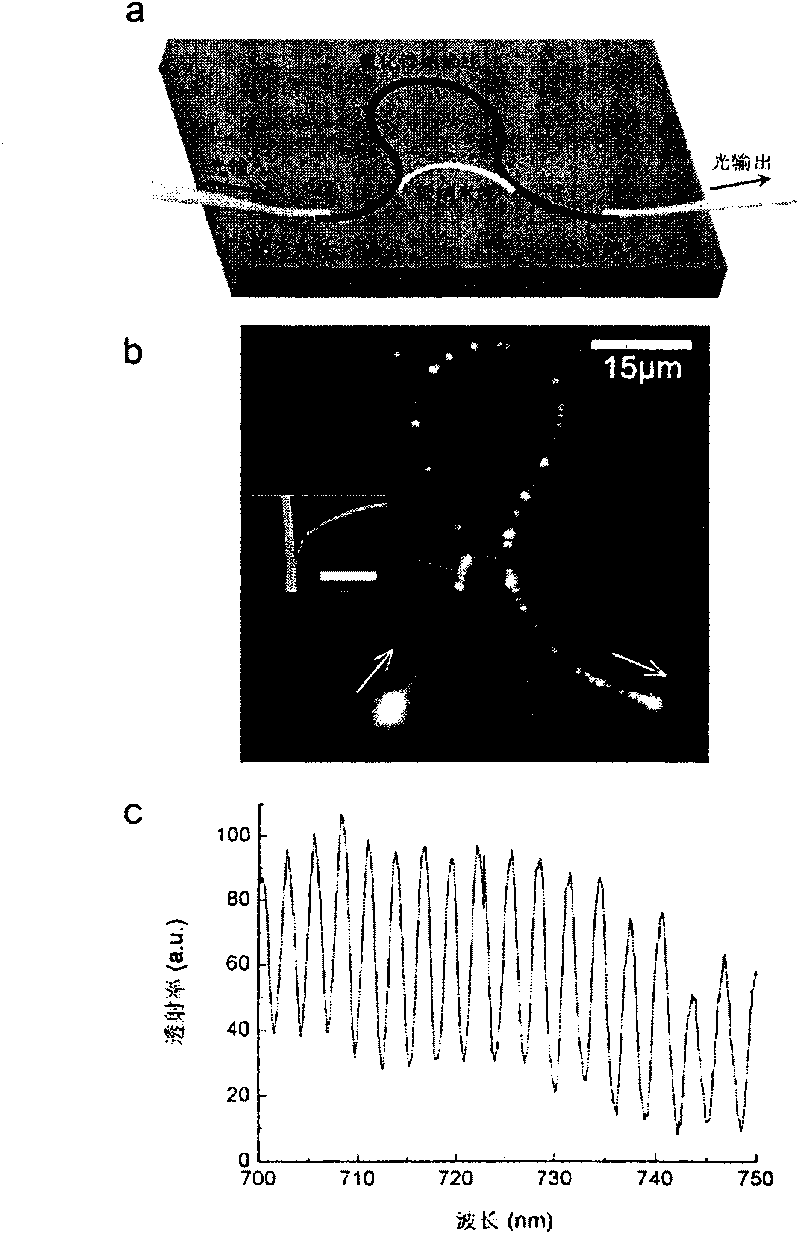

[0012] Such as figure 1 , 2 As shown, the present invention directly couples the nanofiber to the metal nanowire on the substrate to excite the surface plasmon resonance signal of the metal nanowire, or first couples the nanofiber to the optical nanowire and then passes the optical nanowire parallel or at a certain Angle-coupled excitation of metal nanowires. The signal output from the metal nanowire can be coupled out through the optical nanowire, and the output light has good polarization characteristics.

[0013] The diameters of the metal nanowires, nanofibers and optical nanowires are all 50-2000nm. In the composite structure, the coupling efficiency is determined by the overlapping length of the nanowires or the angle between the nanowires. The coupling angle varies ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com