Manufacturing method of bimetal self-lubricating bearing material

A technology of self-lubricating bearing and manufacturing method, applied in the field of bearing materials, can solve the problems of low sliding speed, low bearing capacity, influence on bonding fastness, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

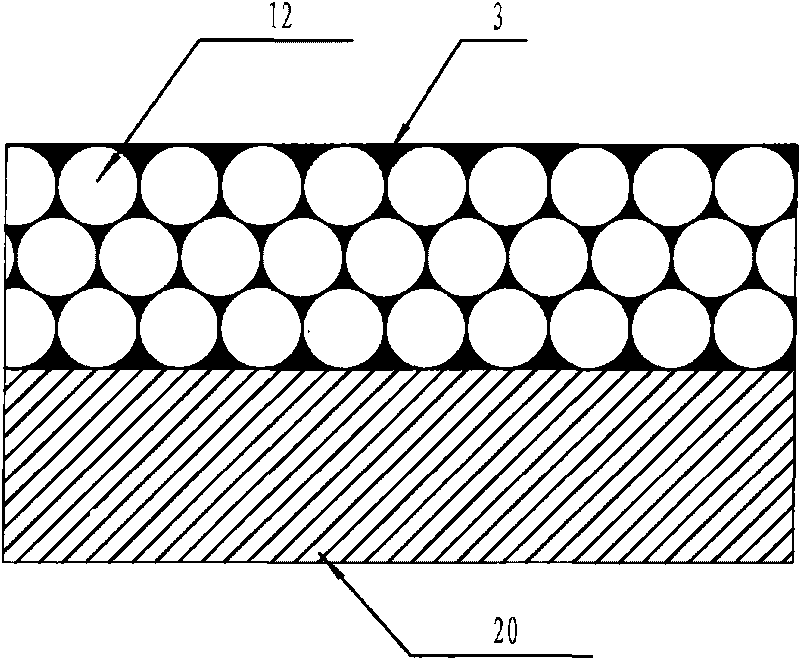

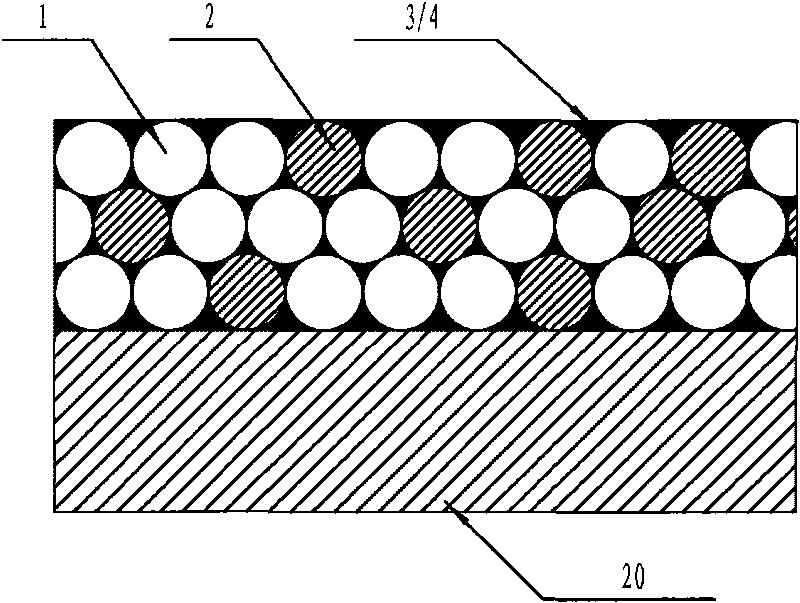

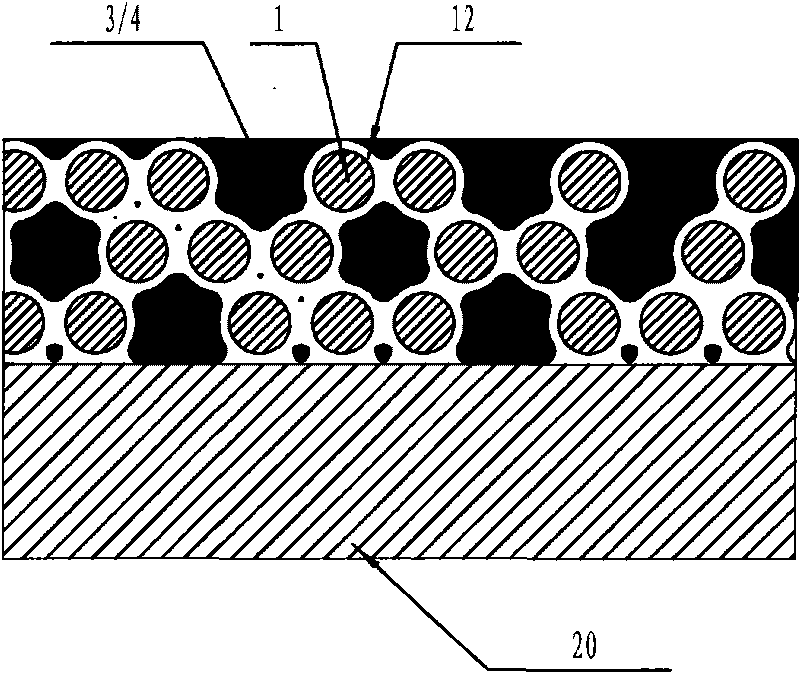

[0021] Using 82% pure copper powder, 5% pure lead powder, 13% pure tin powder and graphite powder accounting for 8% of the total amount of the above metal powders, the particle size is above 200 mesh, and uniformly mixed on a V-shaped mixer , the above percentages are mass percentages; the mixed powder is coated on a steel plate, stainless steel plate or bronze plate for sintering, such as figure 2 As shown, the atmosphere is: vacuum degree ≤ 10Pa, or pure hydrogen with a purity of more than 99.9%, or liquid ammonia decomposition gas (75% hydrogen, 25% nitrogen).

[0022] The sintering is divided into two steps: the first sintering temperature is 300°C to 800°C to achieve limited connection between copper powders. In this process, tin powder and lead powder with low melting point melt into liquid phase, so that sintering is carried out in the presence of liquid phase. Since tin has a certain solubility in copper, the tin in the liquid phase will dissolve into the copper in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com