A kind of method using anthracite as raw material to prepare graphene

A technology of anthracite and graphene, applied in the direction of graphene, single-layer graphene, nano-carbon, etc., can solve the problem of high cost of graphene preparation, achieve the effect of complete sheet structure, improve compatibility, and increase yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

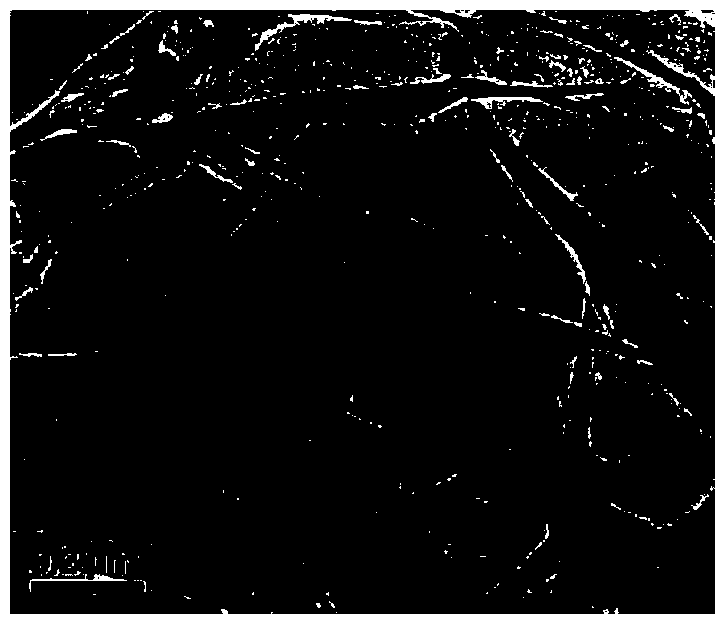

Image

Examples

Embodiment 1

[0036] Put Taixi anthracite into a graphitization furnace, remove the oxygen in the furnace, and calcinate at 2900°C for 6 hours to obtain coal-based graphite. Nitrogen (N 2 ) as a protective gas, the gas flow rate is 1-1.5L / min.

[0037] Add an appropriate amount of 10mol / L concentrated phosphoric acid to a 250mL reaction flask, place the reaction flask in an ice bath, add a solid mixture of coal-based graphite and sodium acetate, the mass ratio of coal-based graphite and sodium acetate is 2.5:1, and then Add potassium permanganate, the mass ratio of potassium permanganate to coal-based graphite is 2:1, then add maleic anhydride, the mass ratio of maleic anhydride to coal-based graphite is 2:1.

[0038] Control the reaction temperature to ≤40°C, stir for 1 hour, raise the temperature to about 60°C, continue to stir for 30 minutes, then slowly add a certain amount of deionized water into the container, stir and then let it stand for 20 minutes, then add an appropriate amount o...

Embodiment 2

[0043] Put Taixi anthracite into a graphitization furnace, remove the oxygen in the furnace, and calcinate at 3150°C for 4.5 hours to obtain coal-based graphite. Nitrogen (N 2 ) as a protective gas, the gas flow rate is 1-1.5L / min.

[0044] Add an appropriate amount of concentrated phosphoric acid to a 250mL reaction bottle, place the reaction bottle in an ice bath, add a solid mixture of coal-based graphite and sodium acetate, the mass ratio of coal-based graphite and sodium carbonate is 2:1, and then add permanganate Potassium, the mass ratio of potassium permanganate to coal-based graphite is 2.5:1, and then EDTA is added, and the mass ratio of EDTA to coal-based graphite is 2.5:1.

[0045] Control the reaction temperature to ≤40°C, stir for 1.5 hours, raise the temperature to about 75°C, continue to stir for 40 minutes, then slowly add a certain amount of deionized water into the container, stir and then let it stand for 25 minutes, then add an appropriate amount of hydrog...

Embodiment 3

[0050] Put the Taixi anthracite into the graphitization furnace, remove the oxygen in the furnace, and calcinate at 3200°C for 3 hours to obtain coal-based graphite. Nitrogen (N 2 ) as a protective gas, the gas flow rate is 1-1.5L / min.

[0051] Add an appropriate amount of concentrated phosphoric acid to a 250mL reaction bottle, place the reaction bottle in an ice bath, add a solid mixture of coal-based graphite and sodium acetate, the mass ratio of coal-based graphite and potassium phosphate is 1.5:1, and then add permanganate Potassium, the mass ratio of potassium permanganate and coal-based graphite is 3:1, and then dodecylbenzenesulfonic acid is added, and the mass ratio of dodecylbenzenesulfonic acid and coal-based graphite is 3:1.

[0052] Control the reaction temperature to ≤40°C, stir for 2 hours, raise the temperature to about 90°C, continue to stir for 50 minutes, then slowly add a certain amount of deionized water into the container, stir and then let it stand for 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com