Direct lead smelting method for processing zinc smelting slag by matching

A technology for zinc smelting slag and lead smelting, which is applied in the direction of improving process efficiency, etc., to achieve the effects of high recovery rate of valuable metals, large equipment processing capacity and strong adaptability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

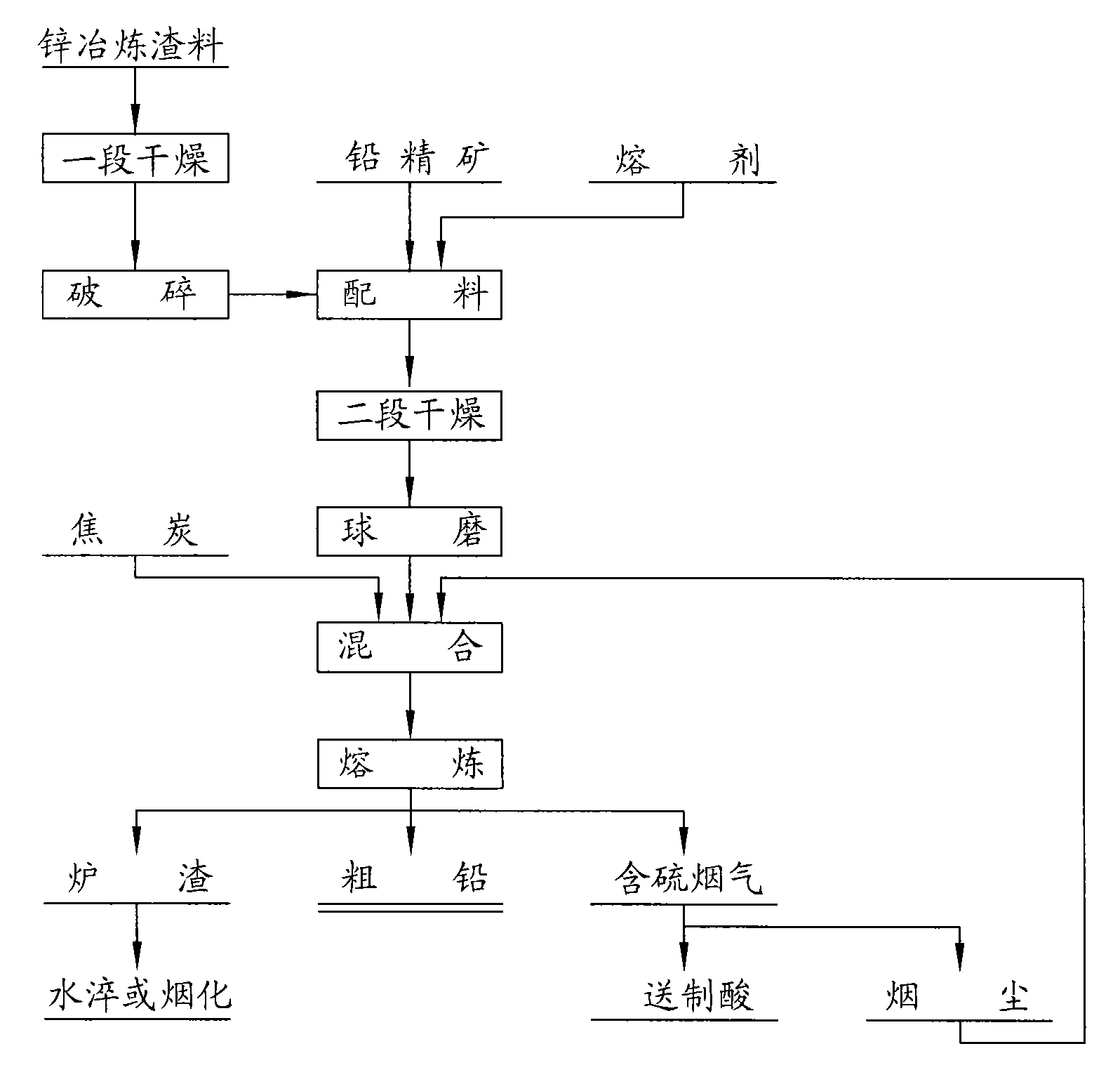

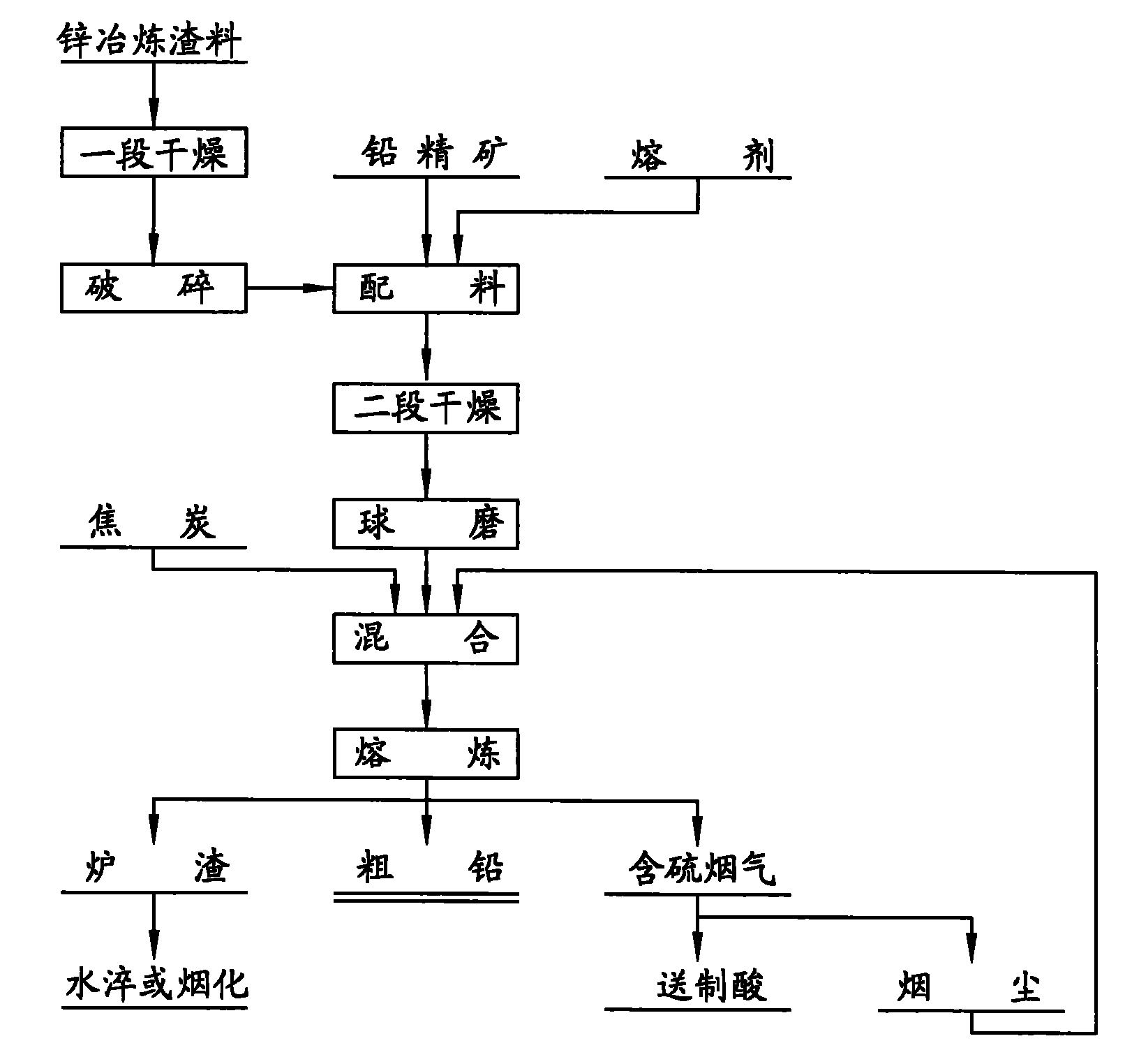

[0013] From figure 1 It can be seen that the present invention is matched with a specific example of the direct lead smelting method for zinc smelting slag. The zinc smelting slag (such as zinc leaching slag) sent from zinc smelting is first dried to a water content of ≤10%, and then mixed with lead concentrate. Batching of ore and flux together (the proportion of zinc smelting slag can be 0-50%, and the proportion of flux is determined according to the content of Fe, Si, and Ca in the charge.) to obtain a lead-containing charge with stable composition, and then carry out secondary drying To water content ≤ 1%, after drying, carry out ball milling to particle size < 1mm, then mix evenly with coke and return fumes from the smelting process, continuously add oxygen material nozzle, and enter the lead smelting furnace together with industrial pure oxygen for flash smelting, and obtain products respectively Crude lead and by-product secondary zinc oxide are quenched in water or s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com