Off-line cleaning method of filter press nylon filtration fabric based on iron ore concentrate slurry dehydration blocking invalidation

A technology of nylon filter cloth and filter press, which is applied in separation methods, filtration separation, chemical instruments and methods, etc. It can solve the problems of difficult site layout, uneven washing, and large number of filter plates, and reduce the consumption of filter cloth and product cost, reduced chemical consumption, and simple cleaning methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1) Select the used filter cloth blocked by iron concentrate powder for the first time, shake off and collect the iron sticky ore powder on the surface of the filter cloth, remove the damaged or severely worn filter cloth, and clean the filter cloth to be cleaned Classify, determine whether it is the "upper filtrate" or "lower filtrate" filter cloth, and make a clear mark.

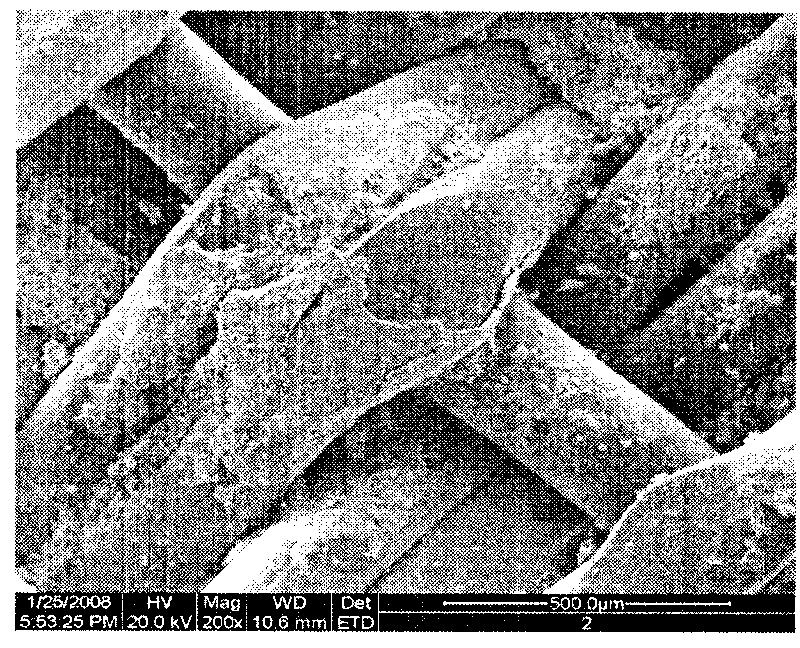

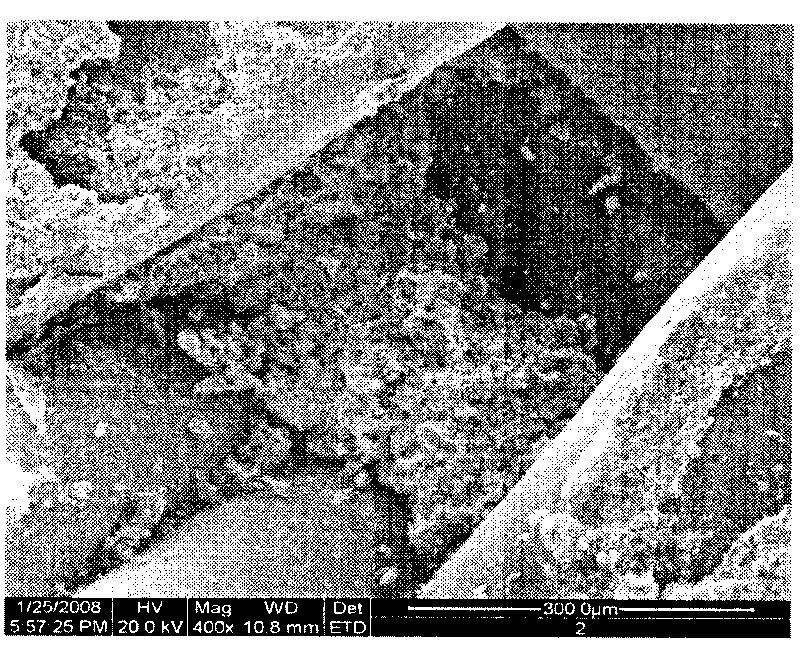

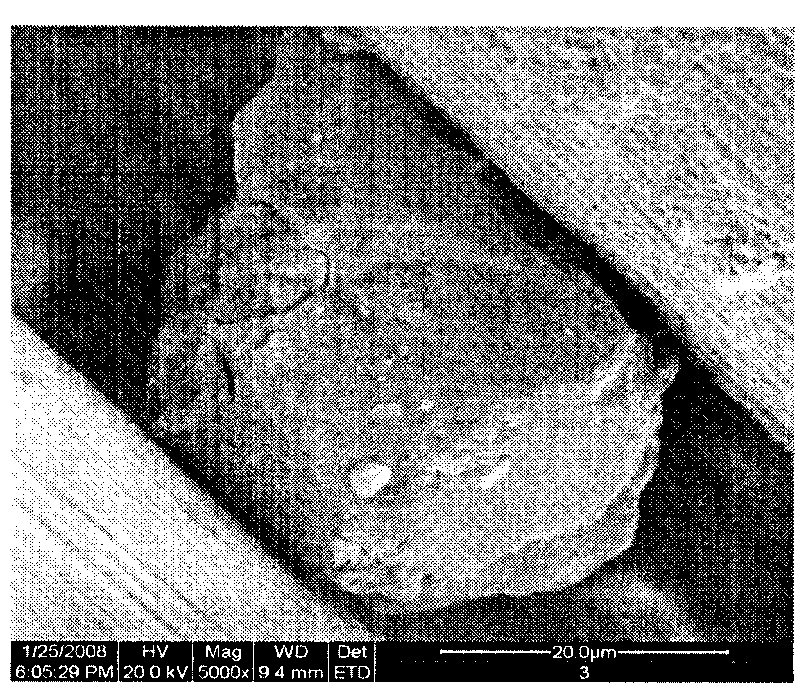

[0044] 2) Lay the selected and classified clogged filter cloth on the metal net of the washing pool, use the washing circulating water after the iron ore particles settle as the washing medium, and spray 50-150kg / cm2 from the plunger pump through the spray gun 2 The high-pressure water jet of water pressure scans and washes the two sides of the filter cloth in sequence until there is basically no black iron ore powder remaining by visual inspection.

[0045] After the iron ore concentrate particles in the flushing water flow through the sedimentation tank, the iron ore powder is deposited at the bott...

Embodiment 2

[0057] 1) Select the used filter cloth blocked by concentrate powder for the first time, shake off and collect the iron concentrate powder on the surface of the filter cloth, remove the damaged or severely worn filter cloth, and clean the filter cloth to be cleaned Classify, determine whether it is "upper filtrate" or "lower filtrate" filter cloth, and make obvious marks;

[0058] 2) Soak the selected filter cloth in a soaking tank filled with chemical cleaning solution for 2 to 4 hours. The composition range of the cleaning solution is shown in the table below:

[0059]

[0060] When preparing chemical cleaning solution, first inject tap water into the immersion tank to reach 2 / 3 of its total depth, calculate the amount of water injected according to the area of the immersion tank and water injection depth, and then combine the effective concentrations of various chemical substances in the above table, according to the above table The upper limit of the concentration is ...

Embodiment 3

[0069] 1) Select the used filter cloth blocked by iron concentrate powder for the first time, shake off and collect the iron concentrate powder on the surface of the filter cloth, remove the damaged or severely worn filter cloth, and clean the filter cloth to be cleaned Classification, determine whether it is the "upper filtrate" or "lower filtrate" filter cloth, and clearly mark it;

[0070] 2) Lay the selected and classified clogged filter cloth on the metal net of the washing pool, use the washing circulating water after the iron ore particles settle as the washing medium, and spray 50-150kg / cm2 from the plunger pump through the spray gun 2 The high-pressure water jet of water pressure scans and washes the two sides of the filter cloth in sequence until there is basically no black iron ore powder remaining by visual inspection.

[0071] After the iron ore particles in the flushing water flow through the sedimentation tank, the iron ore powder is deposited at the bottom of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com