Preparation method of bismuth silicate micro crystal

A bismuth silicate and microcrystal technology, applied in chemical instruments and methods, bismuth compounds, inorganic chemistry, etc., can solve the problem that it is difficult to obtain high-purity bismuth silicate nanopowder, and it is not suitable for batch production of bismuth silicate nanopowder , Low production efficiency and other issues, achieve the effect of low raw material price, less impurity phase, and reduce the formation of impurity phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The first step: preparation of bismuth silicate glass

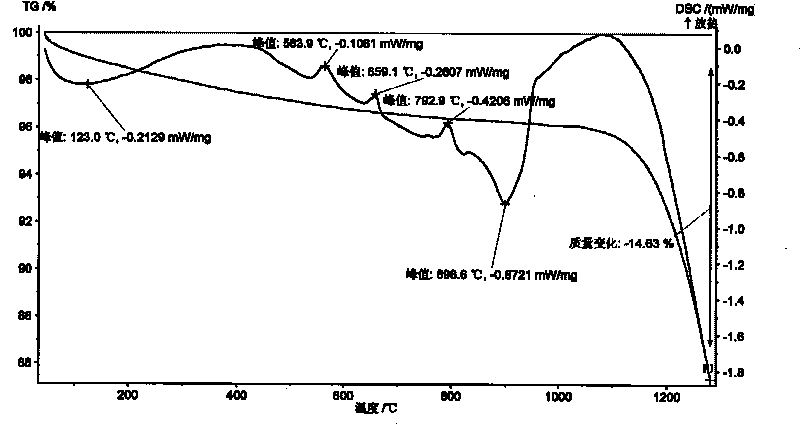

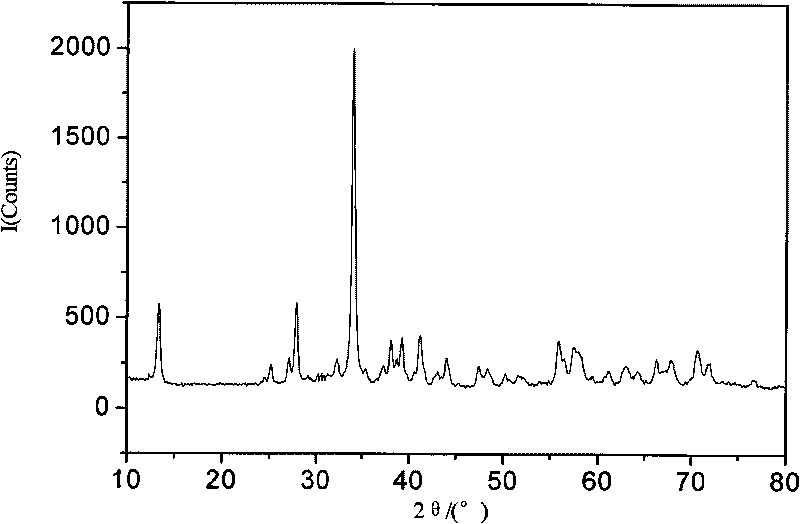

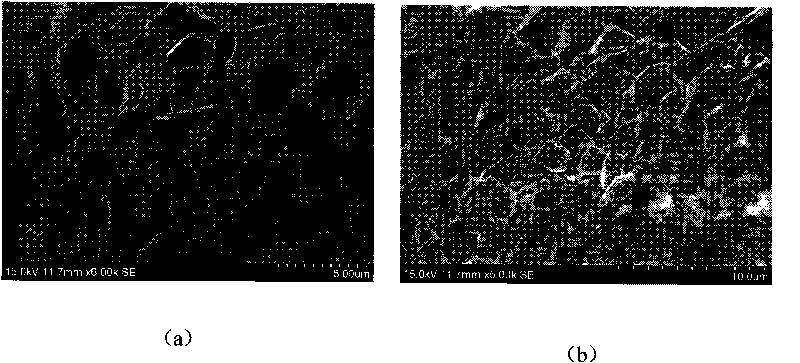

[0022] Firstly, after cleaning and drying the quartz glass with a purity of 4-6N, put it into a ball mill jar and grind it to 300 mesh to make quartz glass powder; then, according to the molar ratio Bi 2 o 3 : SiO 2 = 1: 1 mix bismuth trioxide powder (content is 99.99%) and quartz glass powder and put into the agate emulsion ball mill jar and ball mill for 30min to obtain the batching material; secondly, add the batching material into the muffle furnace in advance In the high-purity alumina crucible with a cover, the temperature of the first feeding is 950°C, and the rest of the batch is added after holding the heat for 30 minutes, and the temperature is raised to 1080°C at 20°C / min. Stir the molten glass with a stainless steel rod for 1 minute every 1 hour; after the heat preservation is over, pour the molten glass into the middle of the rotating iron roller cooled by water, and make the molten glass into a glas...

Embodiment 2

[0028] The first step: preparation of bismuth silicate glass

[0029] Firstly, after cleaning and drying the quartz glass with a purity of 4-6N, put it into a ball mill jar and grind it to 300 mesh to make quartz glass powder; then, according to the molar ratio Bi 2 o 3 : SiO 2 = 1: 1 mix bismuth trioxide powder (content is 99.99%) and quartz glass powder and put into the agate emulsion ball mill jar and ball mill for 50min to obtain the batching material; secondly, add the batching material into the muffle furnace in advance In the high-purity alumina crucible with a cover, the temperature of the first feeding is 960°C, and the rest of the batch is added after keeping it for 25 minutes, and the temperature is raised to 1090°C at 22°C / min. Stir the molten glass for 1 minute, then pour the molten glass into the middle of the iron roller that is rotating on the ground and use water to cool it, and make the molten glass into a glass sheet with a thickness of 1-5mm during the co...

Embodiment 3

[0034] The first step: preparation of bismuth silicate glass

[0035] Firstly, after cleaning and drying the quartz glass with a purity of 4-6N, put it into a ball mill jar and grind it to 300 mesh to make quartz glass powder; then, according to the molar ratio Bi 2 o 3 : SiO 2 = 1: 1 mix bismuth trioxide powder (content is 99.99%) and quartz glass powder and put into agate emulsion ball mill jar and ball mill for 60min to obtain batching material; secondly, add batching material into the muffle furnace in advance In the high-purity alumina crucible with a cover, the temperature of the first feeding is 970°C, and the rest of the batch is added after holding the heat for 20 minutes, and the temperature is raised to 1100°C at 30°C / min. Stir the molten glass with a stainless steel rod for 1 minute every 1 hour; after the heat preservation is over, pour the molten glass into the middle of the rotating iron roller cooled by water, and make the molten glass into a glass with a thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com