Banana ligoglucoside and preparation method and application thereof

A technology of oligodextran and dextran gel, which is applied in application, food preparation, pharmaceutical formulation, etc., can solve the problems of unclear mechanism of action, no identification of banana oligosaccharide extraction and separation structure, etc., so as to adjust the intestinal tract. Micro-ecological environment, easy promotion, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 prepares banana oligodextran according to the following method after the banana is peeled:

[0035] (1) Use an ordinary fruit and vegetable beater to beat the banana pulp, and the beating time is 3 minutes.

[0036] (2) The meat after water leaching and beating, the weight-to-volume ratio of feed to liquid is 1g: 3ml, the temperature is 70°C, the extraction time is 80min, and the extraction is 3 times; the 3 extractions are combined, and then precipitated with 4 times the volume of absolute ethanol 1. Centrifuge at a speed of 4000 rpm for 20 minutes, collect the precipitate, and obtain the banana crude oligosaccharide liquid;

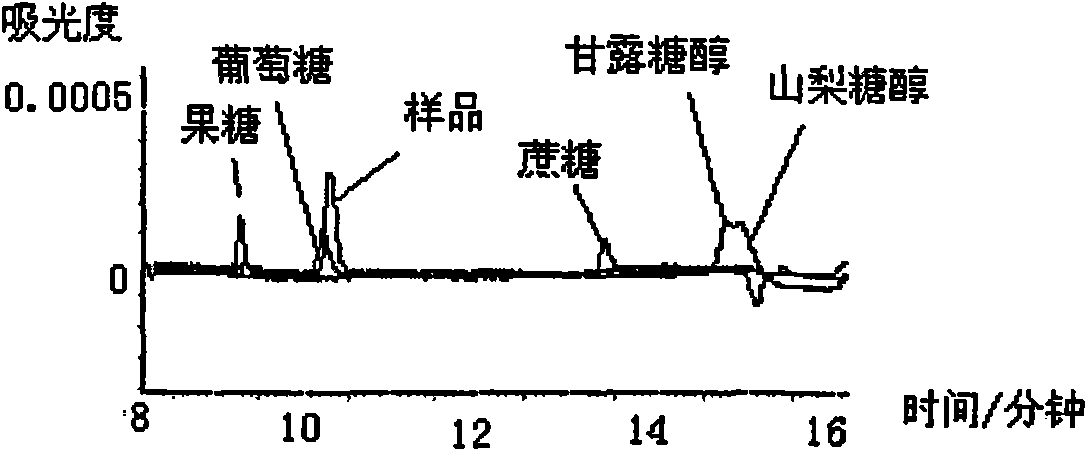

[0037] (3) Sephadex G-100 was selected for chromatographic purification. The chromatographic column was 30cm long and 3cm in diameter. The gel chromatography conditions were: injection volume 10mL, flow rate 3s / drop, and collection within 5min to 7min eluate;

[0038] (4) Dry for 30 minutes under the conditions of vacuum degree 200...

Embodiment 2

[0040] After the banana is peeled, the banana oligodextran is prepared according to the following method:

[0041](1) Use an ordinary fruit and vegetable beater to beat the banana pulp, and the beating time is 2 minutes.

[0042] (2) The flesh after water leaching and beating, the weight-to-volume ratio of feed to liquid is 1g: 3ml, the temperature is 80°C, the extraction time is 90min, and the extraction is 3 times; the 3 extractions are combined, precipitated with 4 times the volume of absolute ethanol, Centrifuge at a speed of 5000 rpm for 15 minutes to obtain a crude banana oligosaccharide solution;

[0043] (3) SephadexG-100 was selected for chromatographic purification. The chromatographic column was 30cm long and 3cm in diameter. The gel chromatography conditions were: injection volume 10mL, flow rate 3s / drop, and collection within 8min to 10min eluate;

[0044] (4) Drying for 20 minutes under the conditions of vacuum degree 1500Pa and microwave power 2000W to obtain ...

Embodiment 3

[0046] After the banana is peeled, the banana oligodextran is prepared according to the following method:

[0047] (1) Use an ordinary fruit and vegetable beater to beat the banana pulp, the beating time is 2.5min,

[0048] (2) The meat after water leaching and beating, the weight-to-volume ratio of feed to liquid is 1g: 3ml, the temperature is 75°C, the extraction time is 80min, and the extraction is 3 times; the 3 extractions are combined, precipitated with 4 times the volume of absolute ethanol, Centrifuge at a speed of 4500 rpm for 16 minutes to obtain banana crude oligosaccharide liquid;

[0049] (3) Sephadex G-100 was selected for chromatographic purification. The chromatographic column was 30cm long and 3cm in diameter. The gel chromatography conditions were: injection volume 10mL, flow rate 3s / drop, and collection within 6min to 9min eluate;

[0050] (4) Dry for 25 minutes under the conditions of vacuum degree 1800Pa and microwave power 1600W to obtain banana oligode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com