Plastic additive mixed liquor and preparation method and application thereof

A technology of additives and mixed liquids, which is applied in the field of plastic additive mixed liquids and its preparation and application, can solve the problems of poor dispersion and complicated preparation methods of plastic additive powder compositions, and achieve simplified preparation methods, expanded uses, and increased plasticity and the effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

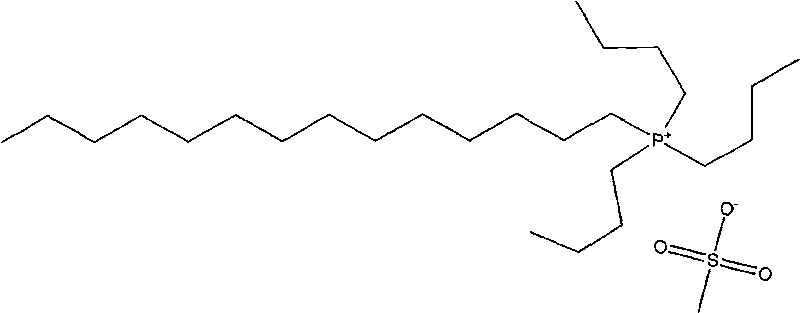

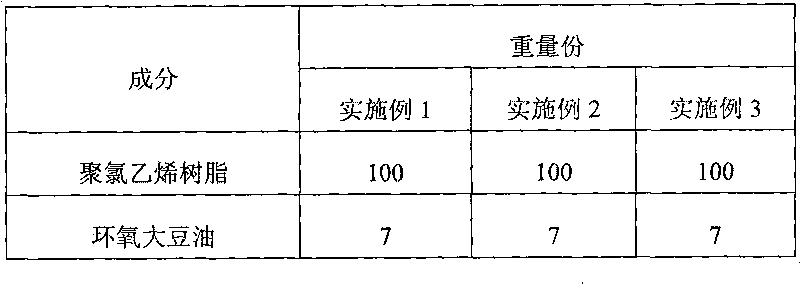

[0041] 27 parts by weight of tributyl (tetradecyl) phosphomethanesulfonate are packed into a 500L dissolution kettle, and then 18 parts by weight of methyl methacrylate-butadiene-styrene ternary graft copolymer impact modification is added. The plastic additive was heated to 100°C in an oil bath, and magnetically stirred for 10 hours to obtain a plastic additive mixture.

[0042] Tributyl (tetradecyl) phosphomethanesulfonate can adopt the product of N / A brand of Bailingwei Chemical Technology Co., Ltd.

[0043] According to the formula in Table 2, each material was premixed and swelled at 110°C. After cooling to 75°C, it was added to a two-stage extruder, plasticized at 150°C, extruded and granulated to obtain the product.

[0044] SEIKO DSC 6200 was used to test the melting point (Tm), glass transition temperature (Tg) and heat enthalpy (ΔH) of the obtained product, and the differences of the test results are shown in Table 1.

[0045] The obtained products were processed on...

Embodiment 2

[0048] Put 35 parts by weight of 1-butyl-3-methylimidazolium hexafluorophosphate into a 500L dissolution kettle, and then add 15 parts by weight of methyl methacrylate-butadiene-styrene ternary graft copolymer for impact modification The plastic additive was heated to 120° C. in an oil bath, and magnetically stirred for 6 hours to obtain a plastic additive mixture.

[0049]1-butyl-3-methylimidazolium hexafluorophosphate can be the product with the brand name 174501-64-5 of Bailingwei Chemical Technology Co., Ltd.

[0050] According to the formula in Table 2, each material was premixed and swelled at 120°C. After cooling to 80°C, it was added to a two-stage extruder, plasticized at 130°C, extruded and granulated to obtain the product.

[0051] Using the same method as in Example 1, the Tm, Tg and ΔH tests were carried out, and the differences of the test results are shown in Table 1.

[0052] The same method as in Example 1 was used to test the impact strength, and the impact ...

Embodiment 3

[0054] Put 52 parts by weight of trihexyl(tetradecyl)phosphorus tetrafluoroborate into a 500L dissolution kettle, then add 13 parts by weight of chlorinated polyethylene impact modifier, heat the oil bath to 160°C, and stir magnetically for 4 hours. Obtain plastic additive mixture.

[0055] Trihexyl (tetradecyl) phosphorus tetrafluoroborate can adopt the product of 374683-55-3 from Bailingwei Chemical Technology Co., Ltd.

[0056] According to the formula in Table 2, each material was premixed and swelled at 130°C. After cooling to 85°C, it was added to a two-stage extruder, plasticized at 160°C, extruded and granulated to obtain the product.

[0057] Using the same method as in Example 1, the Tm, Tg and ΔH tests were carried out, and the differences of the test results are shown in Table 1.

[0058] The same method as in Example 1 was used to test the impact strength, and the impact results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com