Preparation method of liquid crystal polarizing film with characteristic of ultra-wide wave reflection

A polarizer and liquid crystal technology, applied in polarizing elements, optics, instruments, etc., can solve the problems of complicated process, narrow reflected wave width, and narrow application area, and achieve the effects of simple manufacturing process, easy large-scale production, and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

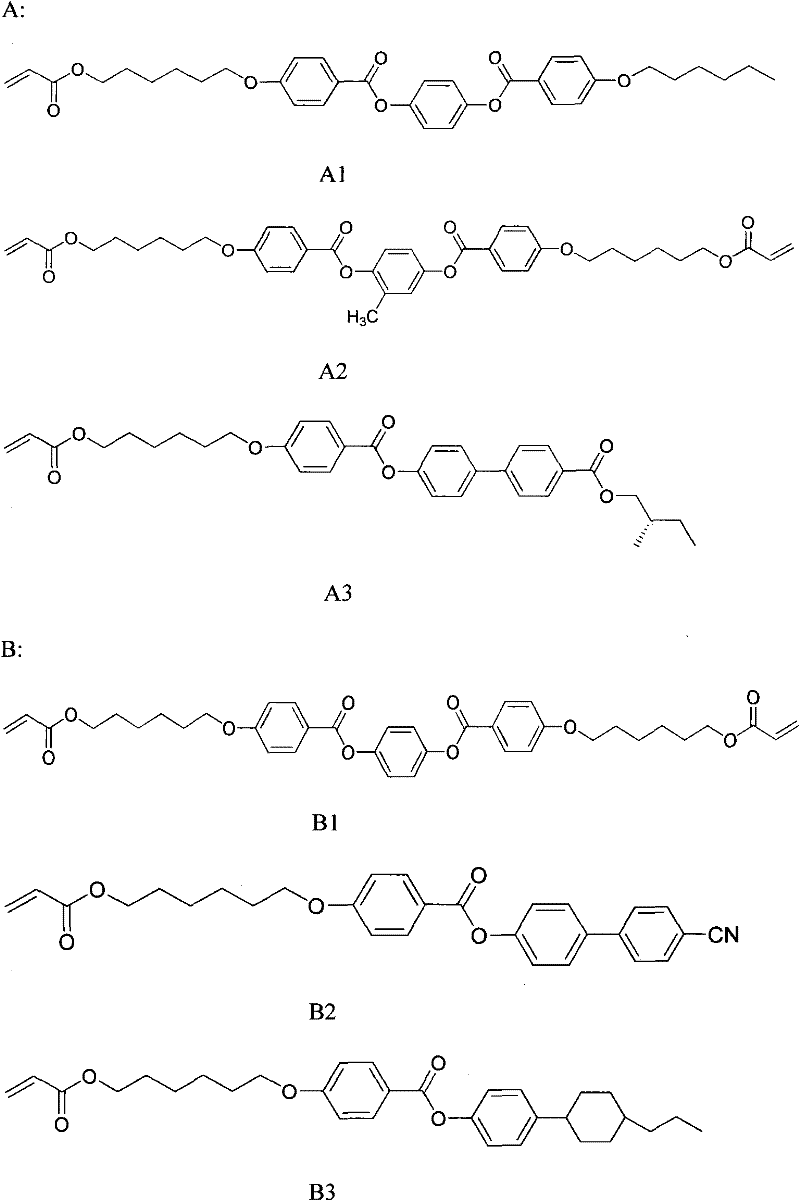

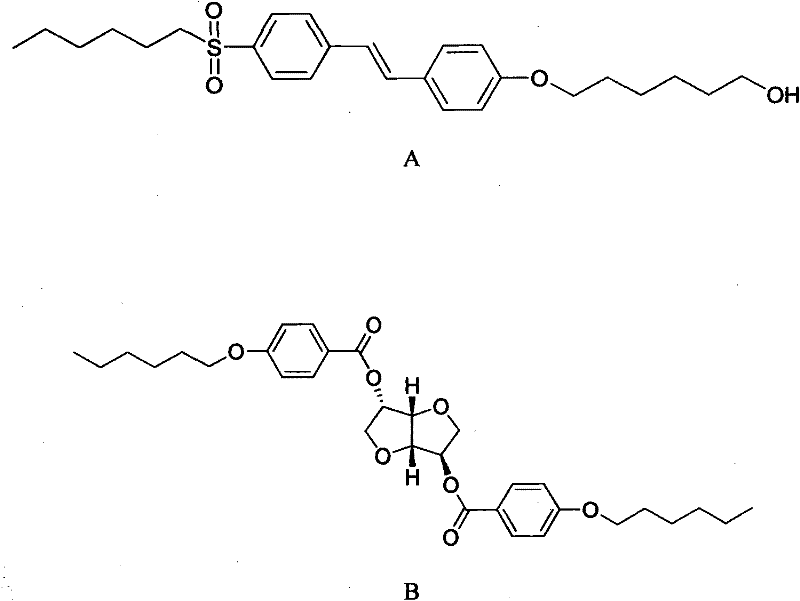

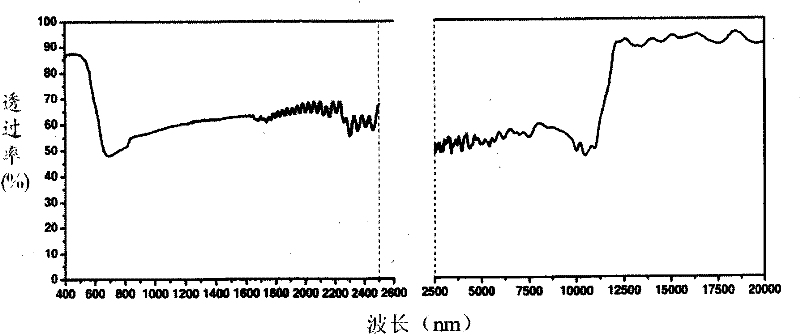

[0029] Mixed liquid crystal: Polyacryloyl photopolymerizable liquid crystal monomer A1, content of 12.9%, monoacryloyl photopolymerizable liquid crystal monomer A2 content of 38.7%, chiral monoacryloyl photopolymerizable liquid crystal monomer A3 content It is 46.4%, the UV absorber is 1.5%, the initiator is Irgacure 651, the content is 0.5%, and the mixture is uniform; the phase transition behavior of the mixture: C45SmA102Ch151I. Pour the mixture at 120℃ into a liquid crystal cell with a thickness of 60μm and anti-parallel orientation after rubbing. The mixture is arranged in a plane, and the temperature is reduced to 109℃. The wavelength is 365nm and the intensity is 0.065mW / cm. 2 Irradiated under UV light for 30 minutes, cured and cross-linked to obtain a liquid crystal polarizer with reflection wavelength above 550-12000nm (such as figure 1 ). The scanning electron micrograph of the cross-sectional structure of the obtained reflective polarizer is as follows figure 2 Shown...

example 2

[0031] Mixed liquid crystal: Multi-diacrylate photopolymerizable liquid crystal monomer B1 content is 14.8%, monodiacrylate photopolymerizable liquid crystal monomer B2 content is 44.7%, monodiacrylate photopolymerizable liquid crystal monomer B3 content It is 32.7%, the chiral additive is cholesterol, the content is 5.2%, the ultraviolet absorber is phosphine salt, the content is 1.8%, the initiator is Irgacure 651, the content is 0.8%, and the mixture is uniform; the phase transition behavior of the mixture: C38SmA95Ch137I . Pour the mixture into a liquid crystal cell with a thickness of 60μm and a rubbing anti-parallel orientation treatment at 115℃, make the mixture align in a plane, cool to 101℃, at a wavelength of 365nm, and an intensity of 0.3mW / cm 2 After being irradiated with the ultraviolet light for 30 minutes, the liquid crystal polarizer with the reflection band of 500-14000nm is obtained after curing and crosslinking.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com