Comprehensively-utilizing process of waste residue containing vanadium, molybdenum, nickel and cobalt

A technology of waste residue and process, applied in the field of comprehensive utilization of waste residue, can solve the problems of occupying land, polluting the environment, wasting iron-containing resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

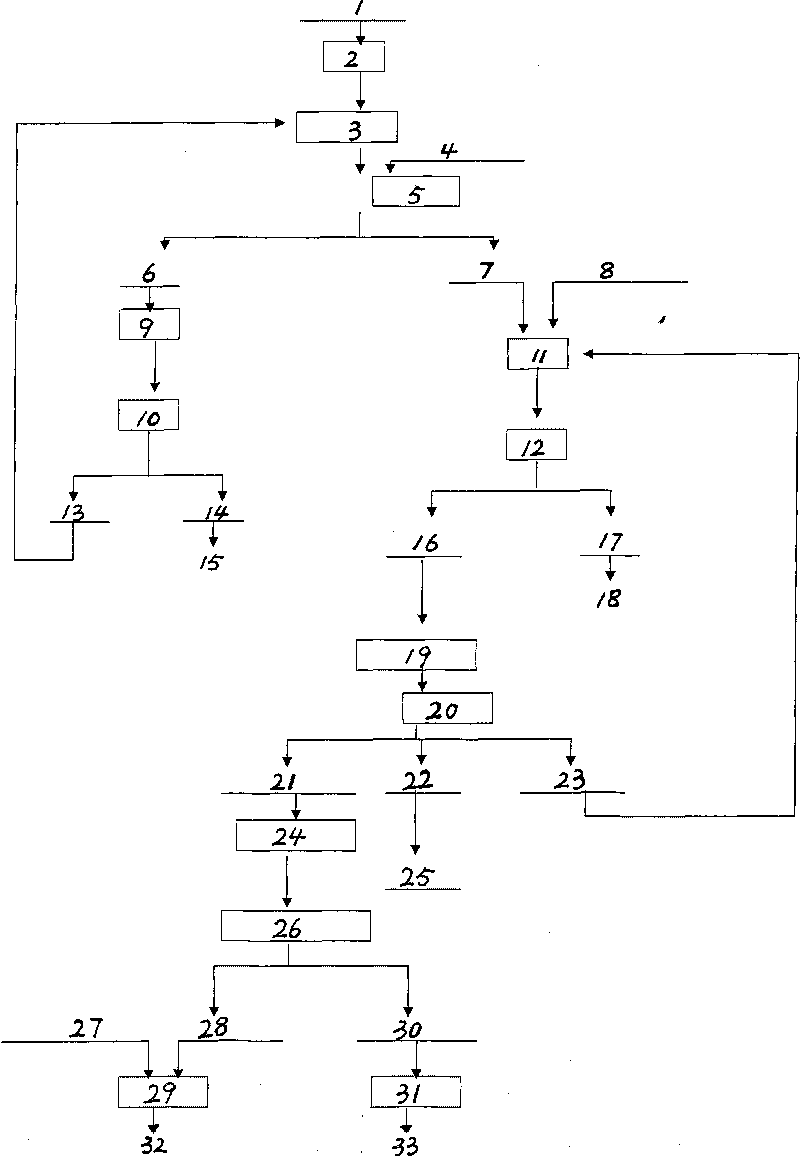

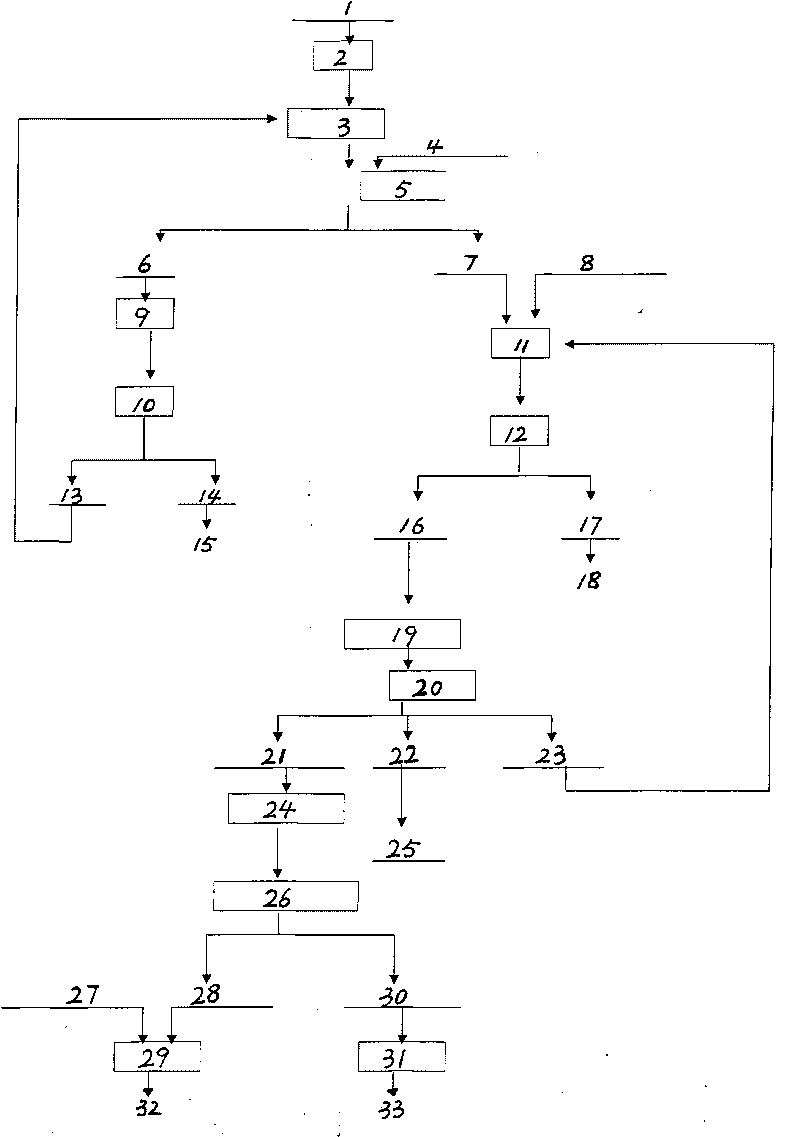

[0067] Introduce technical scheme of the present invention below in conjunction with accompanying drawing: figure 1 Among them, 1 is nickel and iron alloy; 2 is abrasive; 3 is oxygen pressure acid leaching; 4 is H 2 SO 4 o 2 ; 5 is filtration; 6 is leaching residue; 7 is leaching solution; 8 is NaClO 3 、Na 2 CO 3 9 is washing; 10 is filtering; 11 is iron removal; 12 is filtering; 13 is washing water; 14 is leaching slag; 15 is returning to the vanadium pentoxide workshop to reclaim Ni, Co, V, Mo; 16 is after iron removal 17 is iron slag removal; 18 is to return to vanadium pentoxide workshop to reclaim V, Mo; 19 is to remove copper, silicon, aluminum; 20 is to filter; 21 is to remove copper, silicon, aluminum liquid; 22 is to remove copper slag; 23 is silicon and aluminum slag removal; 24 is P204 impurity removal; 25 is copper recovery; 26 is P507 nickel and cobalt separation; 27 is Na 2 CO 3 , NaOH; 28 is CoSO 4 solution; 29 is heavy cobalt carbonate; 30 is NiSO 4 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com