Method for preparing spherical superfine silver powder by using chemical reduction method

A technology of ultrafine silver and reduction method, which is applied in the field of preparing spherical ultrafine silver powder by chemical reduction method, can solve the problems of difficulty in washing, loss of silver powder, low yield, etc., and achieves the effects of low price, less aggregation and good dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Prepare 100ml of silver nitrate solution with a substance concentration of 0.5mol / L and 100ml of an ascorbic acid solution with a substance concentration of 0.25mol / L with deionized water, wherein the ratio of silver nitrate to ascorbic acid is 2:1, and then take silver nitrate 1.5% by mass, that is, 0.127g of gelatin was swelled in hot deionized water with a volume of 20ml at 60°C for half an hour. At room temperature, with the speed of the magnetic stirrer adjusted to 600r / min, the silver nitrate solution was added dropwise to the ascorbic acid solution, gelatin was added dropwise after precipitation occurred, and the pH of the reaction solution was adjusted to 7±0.2 with ammonia water. After the titration, stir for 60 minutes, filter and wash, first wash three times with deionized water, then change to absolute ethanol for three times, dry the washings in a 50°C drying oven, put them in a muffle furnace, and raise the temperature to 350°C at 5°C / min Heat treatment at...

Embodiment 2

[0027] Prepare 100ml of silver nitrate mass concentration with deionized water respectively as a solution of 0.25mol / L and 50ml of ascorbic acid mass concentration as a solution of 0.25mol / L, wherein the ratio of silver nitrate to ascorbic acid mass is 2: 1, then take The gelatin with 1.5% silver nitrate mass, that is 0.0637g, was swelled in hot deionized water with a volume of 20ml at 40°C for half an hour. Under the condition of stirring speed of 400r / min at room temperature, silver nitrate solution was added dropwise to ascorbic acid solution, gelatin was added dropwise after precipitation occurred, and the pH of the reaction solution was adjusted to 7±0.2 with ammonia water. After the titration, stir for 30 minutes, filter and wash, first wash with deionized water three times, then change to absolute ethanol for three times, and dry the washings in a 50°C drying oven, then put them in a muffle furnace, and heat up to 350°C at 5°C / min. Heat treatment at ℃ for one hour to re...

Embodiment 3

[0030] The mass ratio of silver nitrate and ascorbic acid is 2:1, the mass concentration of silver nitrate is 0.5mol / L, and the volume is 100ml, the mass concentration of ascorbic acid is 0.5mol / L, and the volume is 50ml. The dosage of gelatin is 1% by mass of silver nitrate, that is, 0.085g, which is swelled in 20ml of hot deionized water at 50°C for half an hour. Stir at room temperature at a speed of 200r / min, add the silver nitrate solution to the ascorbic acid solution drop by drop, add gelatin drop by drop after precipitation occurs, and adjust the pH of the reaction solution to 6±0.2 with ammonia water. After the titration, stir for 40 minutes to filter and wash. First, wash with deionized water three times and then change to absolute ethanol for three times. The washings are dried in a 50°C drying oven and then put into a muffle furnace. The temperature is raised to 350°C at 5°C / min ℃, heat treatment for one hour to remove impurities.

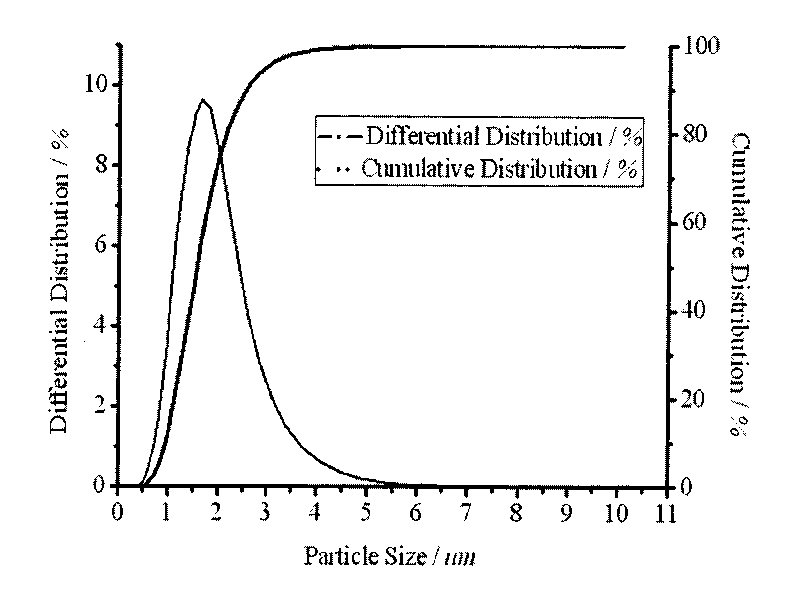

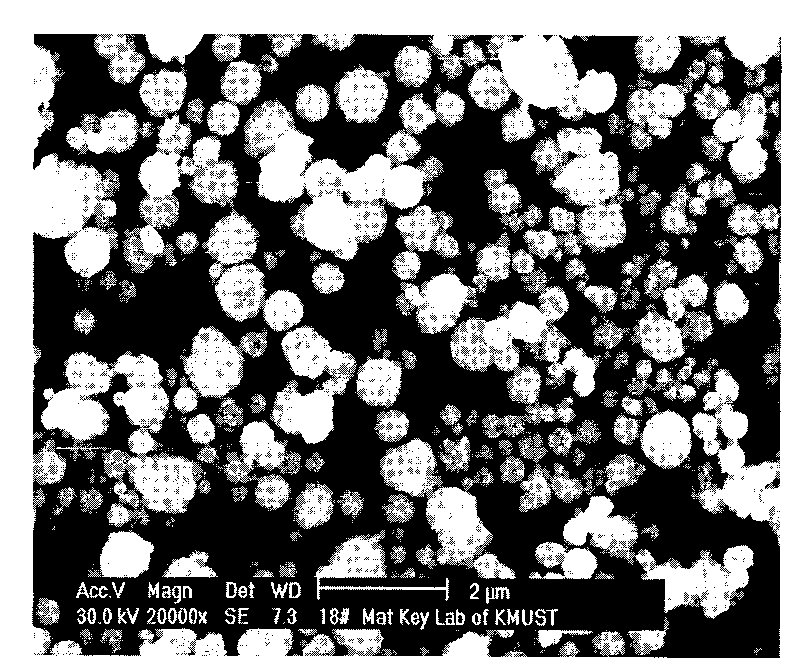

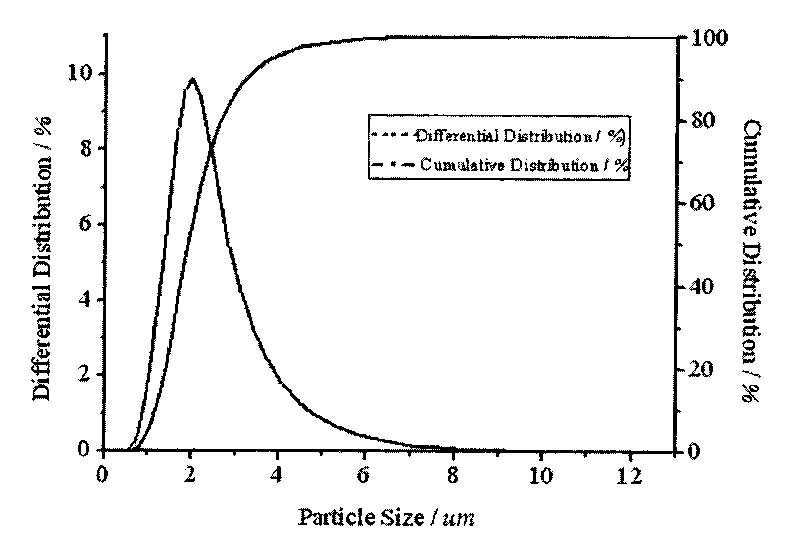

[0031] The particle size and sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com