Preparation method of sulphur and fluorin-doped titanium dioxide nanotube

A titanium dioxide, co-doping technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology and other directions, can solve the problems of high semiconductor carrier recombination rate, low quantum efficiency, harsh immobilization conditions, etc., to improve photoelectric conversion efficiency. , high active specific surface area, easy to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0017] 1) Grind and polish the pure titanium sheet until there are no scratches on the surface, ultrasonically clean it with acetone and deionized water, and dry it;

[0018] 2) Add 0.5M H 2 SO 4 +0.5wt%HF is prepared into electrolyte, and the pH value of the electrolyte is adjusted to be 1.5. With the titanium sheet in step 1) as the anode, and the nickel plate as the cathode, under 20V regulated DC power supply, magnetic stirring is carried out for anodic oxidation reaction for 120 minutes, After the reaction, wash with distilled water and dry in air to obtain amorphous TiO 2 nanotube;

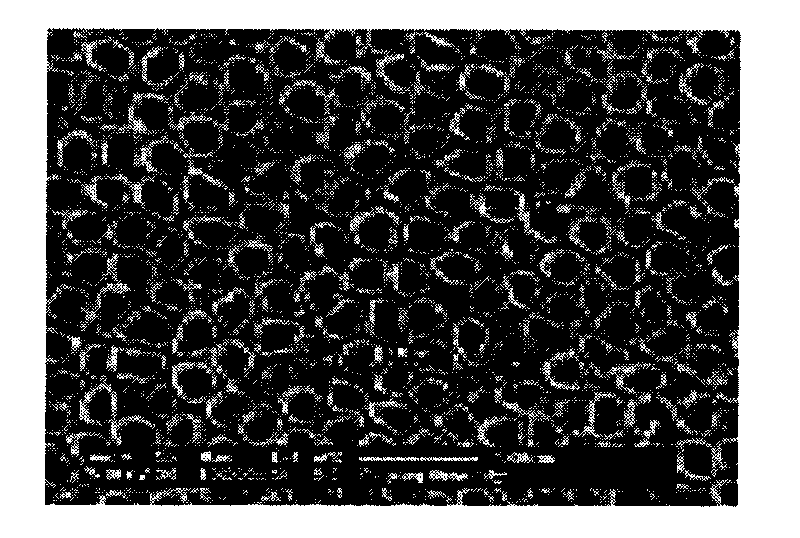

[0019] 3) the prepared amorphous TiO 2 The nanotubes were placed in a heating furnace at 673°C, calcined in the air atmosphere for 2 hours, and cooled naturally to obtain sulfur and fluorine co-doped titanium dioxide nanotubes. It looks like figure 1 It can be seen from the figure that the prepared sulfur and fluorine co-doped titanium dioxide nanotubes have obvious tubular structure. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com