Method and system for exchanging two silicon wafer stages of photoetching machine

A technology for exchanging systems and wafer stages, which is applied in the field of high-efficiency lithography machine dual wafer stage exchanging systems, can solve the problems of insufficient space utilization, processing and assembly accuracy, and shorten exchange time, reduce installation accuracy requirements, The effect of improving system efficiency and space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, structure, principle and working process of the present invention are described further

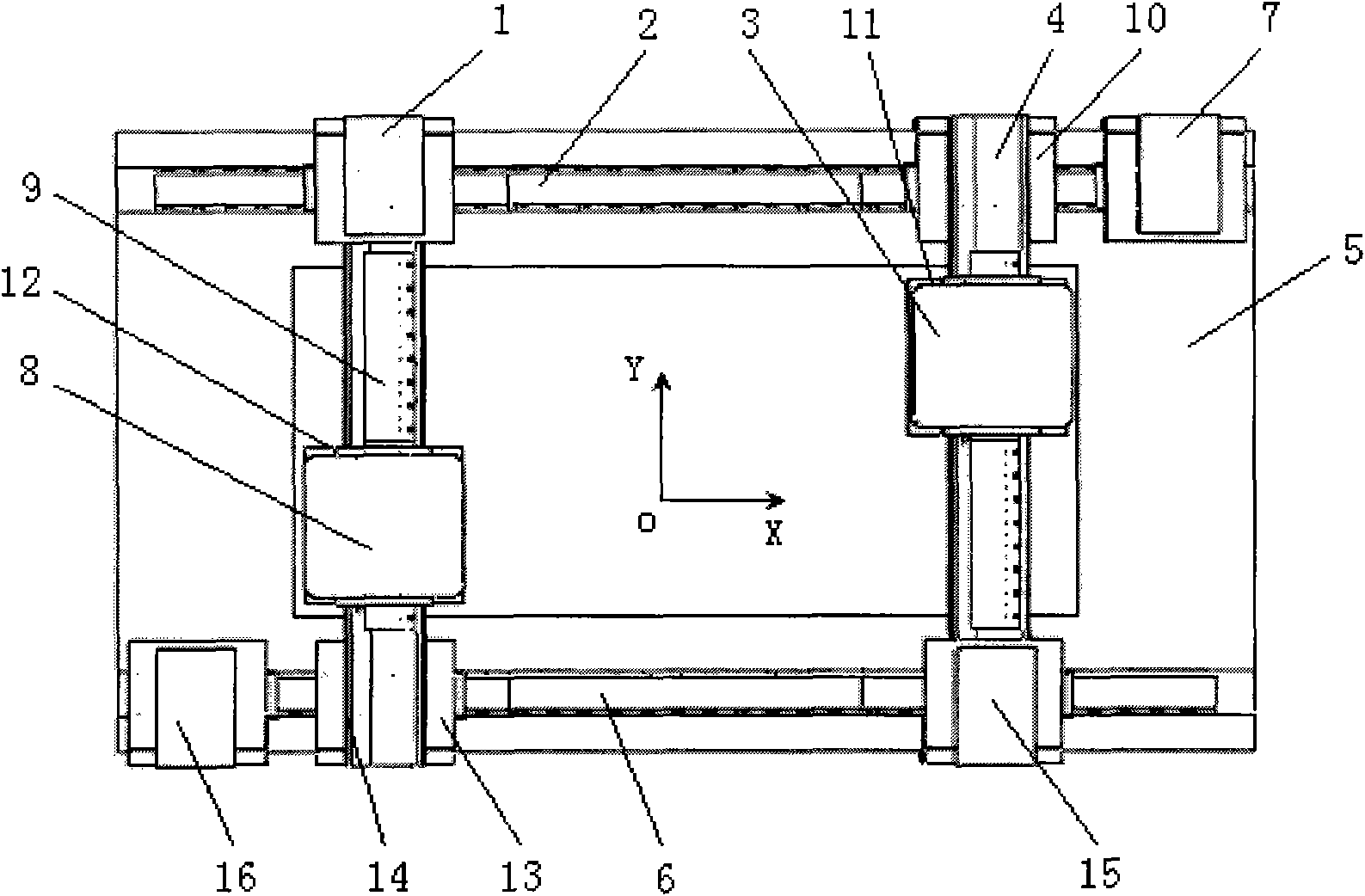

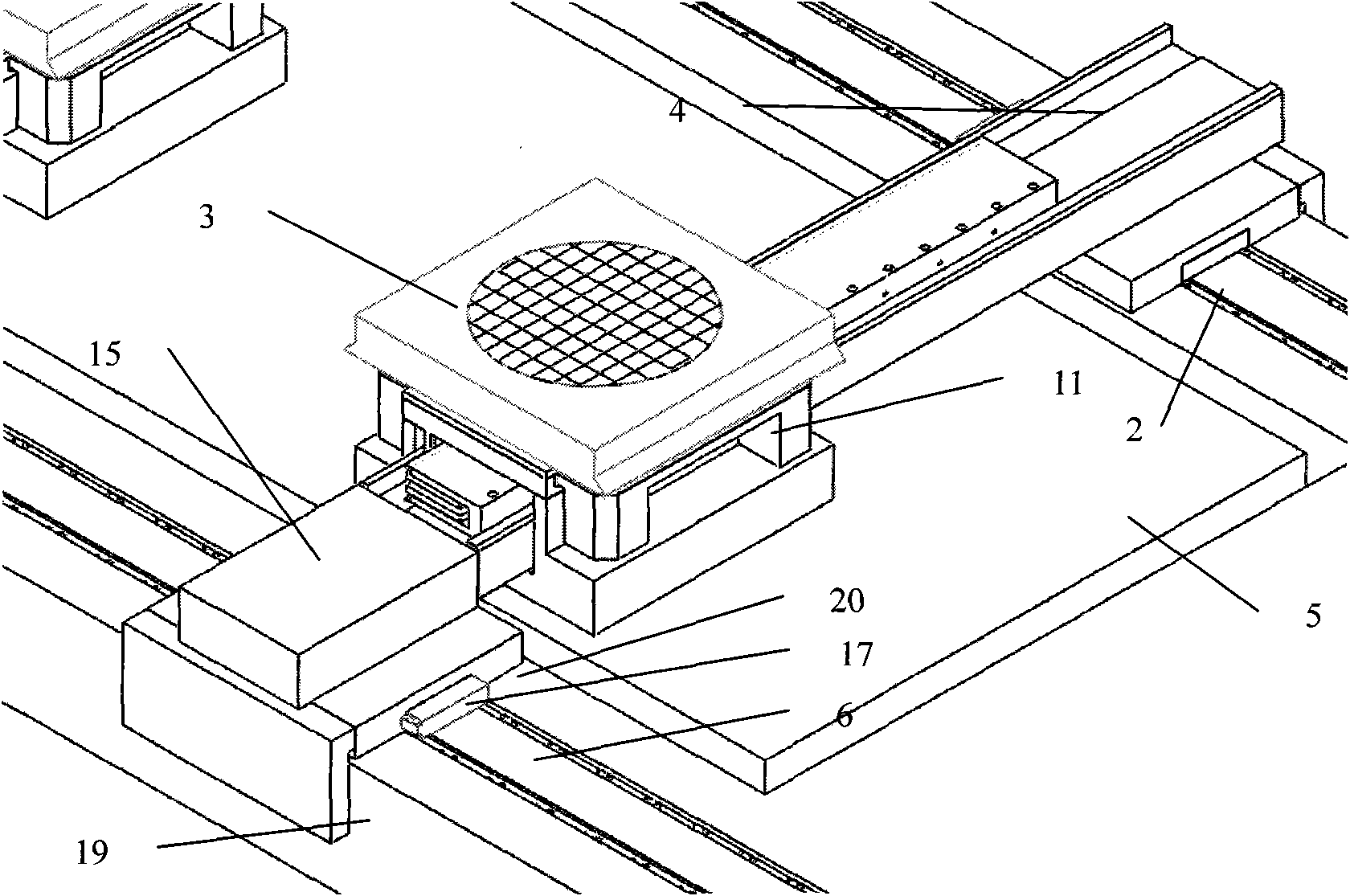

[0027] figure 2 Schematic diagram of the structure of the dual-wafer stage exchange system of the lithography machine provided by the present invention, the system includes the first wafer stage 3 operating at the exposure station, the second wafer stage 8 operating at the pre-processing station, the first X-direction linear guide rail 2, second X-direction linear guide rail 6, first single-degree-of-freedom auxiliary drive unit 1, second single-degree-of-freedom auxiliary drive unit 7, third single-degree-of-freedom auxiliary drive unit 15, fourth single-degree-of-freedom auxiliary drive unit Drive unit 16, first Y-direction guide rail 4, second Y-direction guide rail 9, first wafer stage auxiliary drive unit 11, second wafer stage auxiliary drive unit 12, first main drive unit 10, second main drive unit 13 and the base 5, the long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com