Super capacitance storage battery

A technology of supercapacitors and batteries, applied in capacitors, electrolytic capacitors, circuits, etc., can solve the problems of low utilization rate of active materials of negative plates, low overall power density and cycle life of batteries, etc., and achieve high current charge-discharge cycle life, electrical conductivity Good performance and low impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

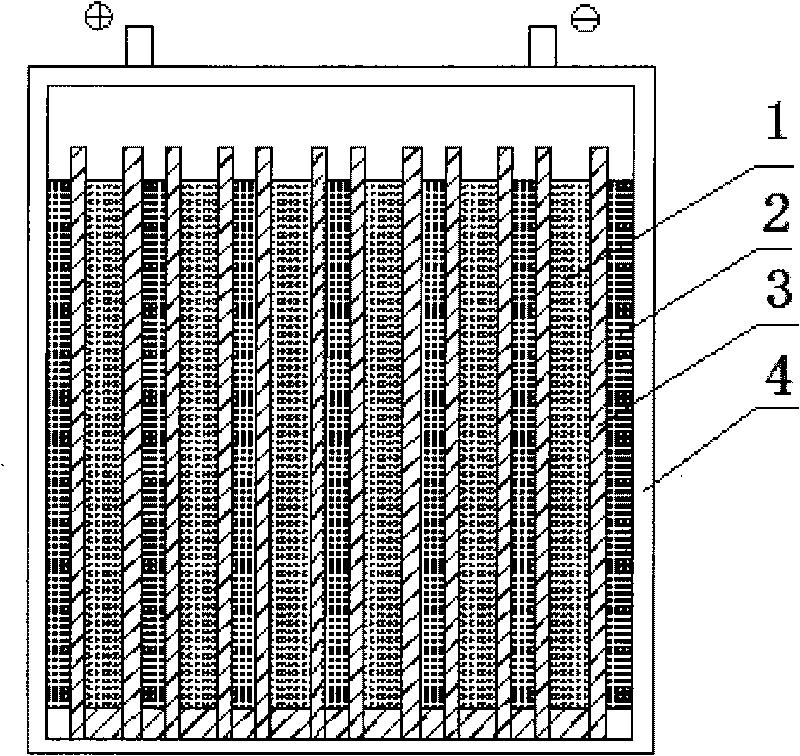

[0038] Embodiment 1: The supercapacitor storage battery provided in this embodiment is mainly used for electric bicycles and consists of six cells connected in series. like figure 1 As shown, each monomer includes six positive plates 1 and seven negative plates 2 arranged at intervals in a casing 4, and a commercial AGM separator 3 is used between adjacent positive plates 1 and negative plates 2 ( Thickness 0.6mm 10KPa) continuous coating, and the electrolyte is dilute sulfuric acid (density 1.28g / cm 3 ).

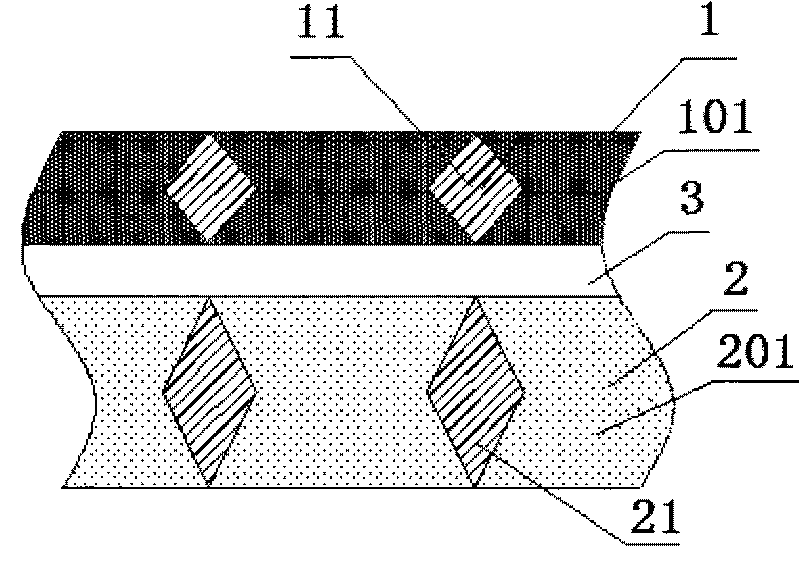

[0039] further combined figure 2 In the partial sectional view of the monomer shown, the positive plate 1 is a positive plate of a lead storage battery, and its specific composition and manufacturing method are as follows:

[0040] The size of the positive grid 11 is: 68mm×44mm×2.8mm, and it is made of lead-antimony-cadmium alloy with 1.6% antimony content and 1.2% cadmium content.

[0041] The lead storage battery positive plate lead paste 101 is coated on the positiv...

Embodiment 2

[0063] This supercapacitor accumulator that embodiment 2 provides, its difference with embodiment 1 is as follows:

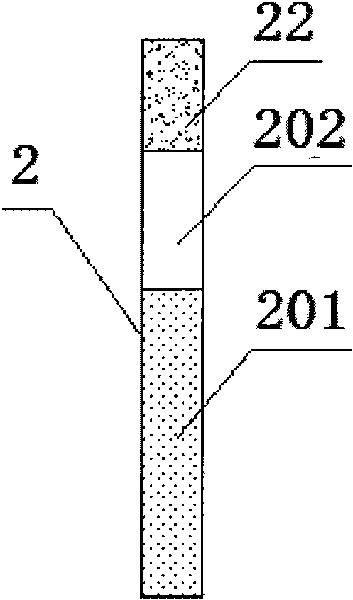

[0064] Capacitor electrode material ratio: activated carbon 70%, graphite powder 15%, acetylene black 5%, PVDF 10%. Dry mix activated carbon and acetylene black for 5 minutes, add PVDF N-methylpyrrolidone (NMP) solution, then use an appropriate amount of N-methylpyrrolidone to make a slurry, stir for 1-2 After hours, mix well, roll and dry on a mirror stainless steel plate to make a film with a thickness of about 1mm, and then put it in an oven at 100°C for 2-4 hours to make it completely dry. It will be made into flakes, crushed and properly milled to make granules; sieved, and the parts smaller than 50 mesh and larger than 200 mesh are taken for later use.

[0065] The granular capacitive electrode material that will be made is vacuum-impregnated with deionized water for 30 minutes, then the apparent moisture is removed by vacuum filtration, and added in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com