Composite wood board

一种复合木板、木材的技术,应用在木材加工器具、其他家里用具、扁平制品等方向,能够解决长加工时间、溶胀和水分吸收增加、内部粘接和弯曲强度降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1a

[0030] Preparation of ammonium polycarboxylate-sugar binders for construction of wood fiberboard compositions

[0031] Aqueous triammonium citrate-dextrose (1:6) binder was prepared by the following general procedure: In a 1 gallon reaction vessel, powdered dextrose monohydrate (915 g) and powdered anhydrous citric acid ( 152.5g), to which 880g of distilled water was added. To this mixture was added 265 g of 19% ammonia water with stirring and stirring continued for several minutes to achieve complete dissolution of the solids. To the resulting solution was added 3.3 g of SILQUEST A-1101 silane to prepare a pH-8-9 solution (using pH paper) containing approximately 50% dissolved glucose monohydrate and dissolved ammonium citrate solids (as a percentage of the total weight of the solution); a 2 g sample of this solution was heat cured at 400°F for 30 minutes and it yielded 30% solids (weight loss due to dehydration during thermoset binder formation). Where silanes other than S...

Embodiment 1b

[0036] The following samples were tested to compare the flexural and tensile strengths of standard particleboard and oriented strand board with similar products prepared using the new experimental binder:

[0037] · Commercially available 1 / 2 inch particle board purchased from Builders Lumber

[0038] · Commercially available 1 / 2 inch oriented strand board (OSB) purchased by Builders Lumber

[0039] · Test wood particle board prepared as above

[0040] 8.75×8.87×0.414371.9gm.44.1lbs 3 12.6% binder

[0041] · Test wood shavings board prepared as above

[0042] 8.37×9×0.336361.2gm.54.4lbs 3 12.6% binder

[0043] The plates tested were each about 8 3 / 4 square inches. The boards from builders are about 2ft x 4ft when purchased. Cut these sheets to approximately 8 3 / 4 square inches so that samples are collected consistently from a variety of products.

[0044] The test results are listed in Table 1-5:

[0045] Results summarized in Table 1

[0046]

[0047] Table 2 D...

Embodiment 2

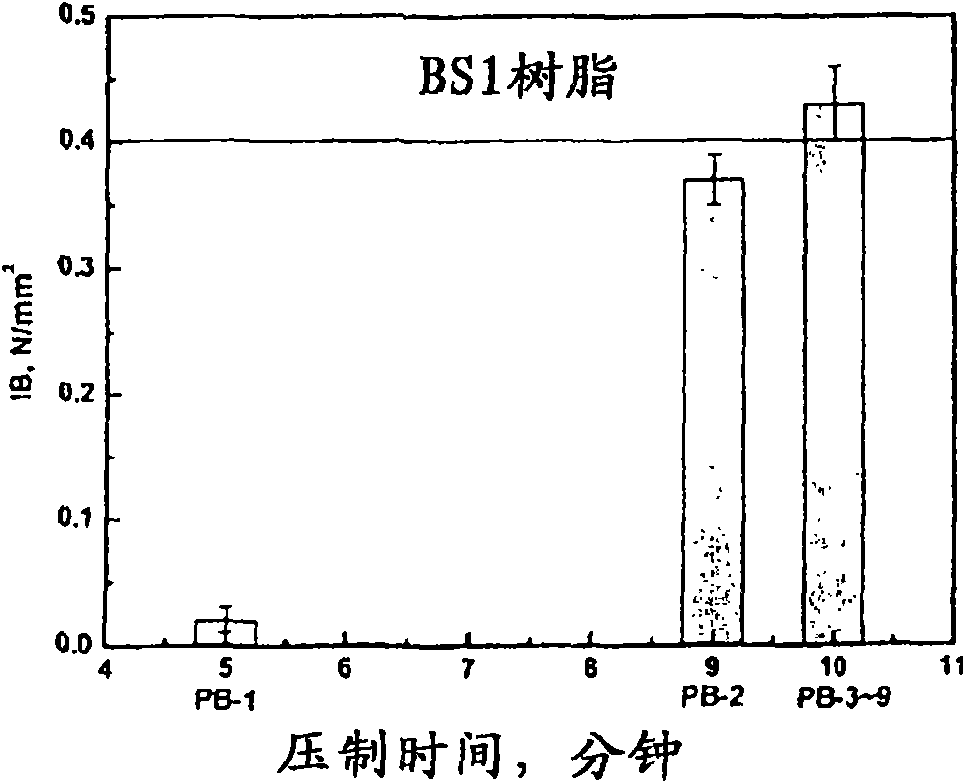

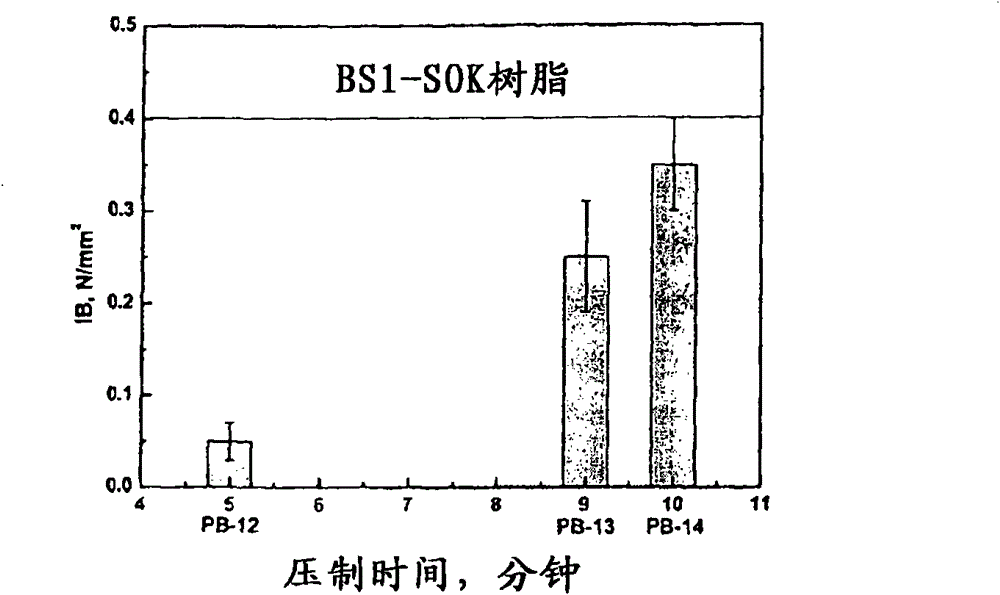

[0056] Two experimental resins were used, BS1 and BS1-SOK (50% solids content). These two resin systems are used to manufacture particle board (PB), oriented strand board (OSB) and medium density fiberboard (MDF).

[0057] Trial Particleboard Fabrication

[0058] Manufacture single layer particle board. The wood chips used in the manufacture of particleboard are the wood chips used in the manufacture of commercial particle boards which consist of a mixture of wood-like substances and which are believed to consist mainly of reclaimed wood. Sift wood chips before using to remove oversized material and debris. Dry the wood chips to a constant moisture content (MC) before resin treatment. Hereinafter, the moisture content will be expressed as the weight of moisture contained in the wood as a percentage of the weight of the oven-dried wood.

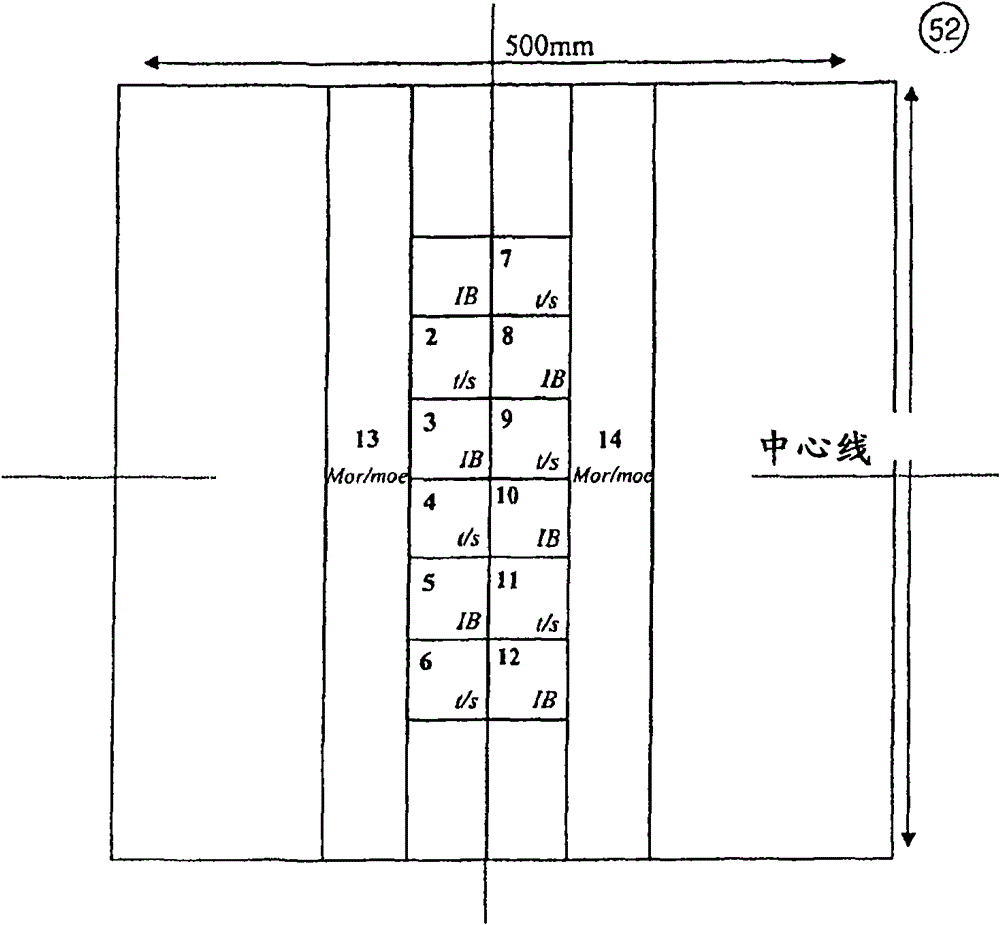

[0059] 12% or 14% resin was added to the wood chips (weight of resin solids relative to weight of dry wood). The resin and wood chips ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com