Low-cost hydrogenation process method

A process method, low-cost technology, applied in the field of fixed-bed three-phase hydrogenation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

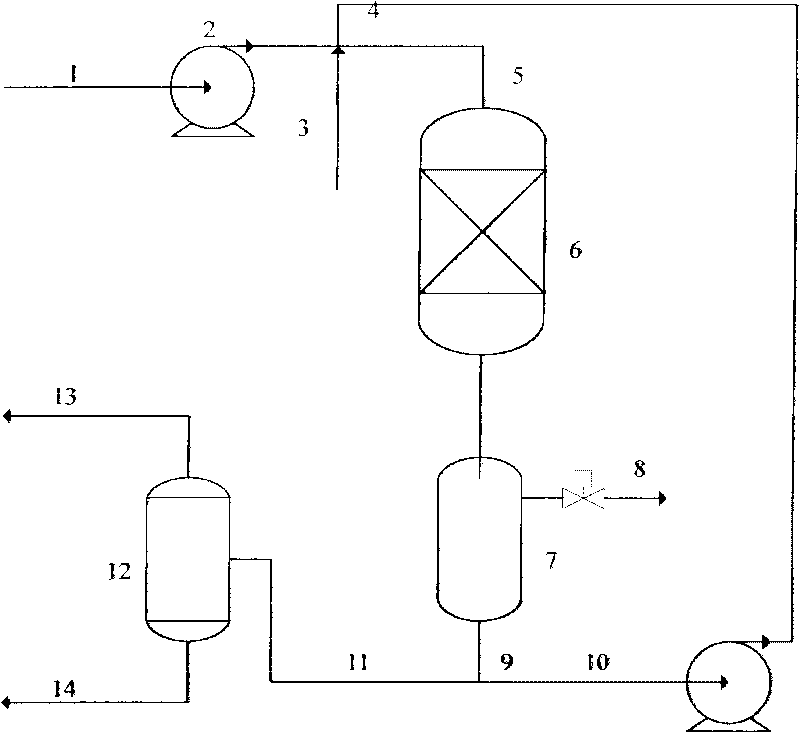

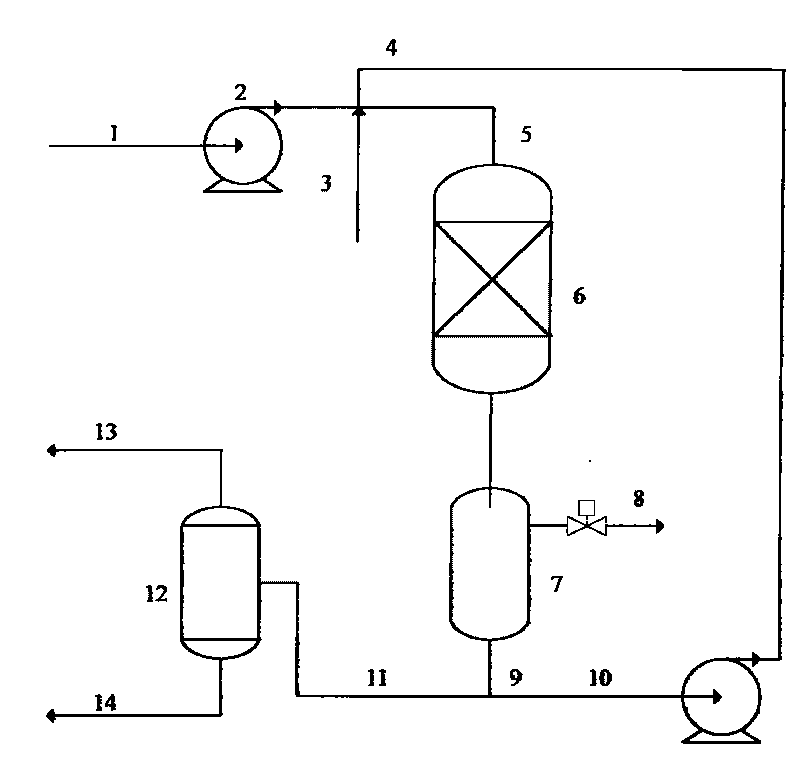

Image

Examples

Embodiment 1

[0021] Gasoline feedstock was desulfurized by hydrotreating at 230°C, and the catalyst was FDS-4A catalyst developed and produced by Fushun Petrochemical Research Institute. The chemical hydrogen consumption of the reaction and the dissolved hydrogen in the system are tested first, and then the method process of the present invention is carried out. The reaction pressure is 3.0MPa, and the volumetric space velocity of the reaction raw material oil is 4h -1 . The volume ratio of hydrogen to oil is based on the reaction chemical hydrogen consumption plus twice the amount of dissolved hydrogen in the system, and the circulation ratio (circulation oil volume: fresh raw material volume) is 2:1. The reaction result is a desulfurization rate of 99.7%, which is basically equivalent to the reaction effect under the existing high hydrogen-to-oil ratio operating conditions, and the stability of the catalyst activity is equivalent to that under ordinary conditions.

Embodiment 2

[0029] Aviation coal is desulfurized by hydrotreating at 290°C, and the catalyst is FH-40A catalyst developed and produced by Fushun Petrochemical Research Institute. The chemical hydrogen consumption of the reaction and the dissolved hydrogen in the system are tested first, and then the method process of the present invention is carried out. The reaction pressure is 4.0MPa, and the volume space velocity of the reaction raw material oil is 2h -1 . The volume ratio of hydrogen to oil is based on the reaction chemical hydrogen consumption plus 1.5 times the dissolved hydrogen in the system, and the circulation ratio (circulation oil volume: fresh raw material volume) is 0.3:1. The reaction result is a desulfurization rate of 99.5%, which is basically equivalent to the reaction effect under the existing high hydrogen-to-oil ratio operating conditions, and the stability of the catalyst activity is equivalent to that under ordinary conditions.

Embodiment 3

[0031] Diesel feedstock is hydrorefined at 350°C for desulfurization and denitrogenation, and the catalyst is FHDS-6 catalyst developed and produced by Fushun Petrochemical Research Institute. The chemical hydrogen consumption of the reaction and the dissolved hydrogen in the system are tested first, and then the method process of the present invention is carried out. The reaction pressure is 4.0MPa, and the volumetric space velocity of the reaction raw material oil is 1.9h -1. The volume ratio of hydrogen to oil is based on the reaction chemical hydrogen consumption plus 0.8 times the amount of dissolved hydrogen in the system, and the circulation ratio (circulation oil volume: fresh raw material volume) is 2:1. The reaction results show that the desulfurization rate is 99.9%, and the denitrification rate is 99.6%, which are basically equivalent to the reaction effect under the existing high hydrogen-to-oil ratio operating conditions, and the stability of the catalyst activi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com