Marsh gas reactor with crusting resistance device

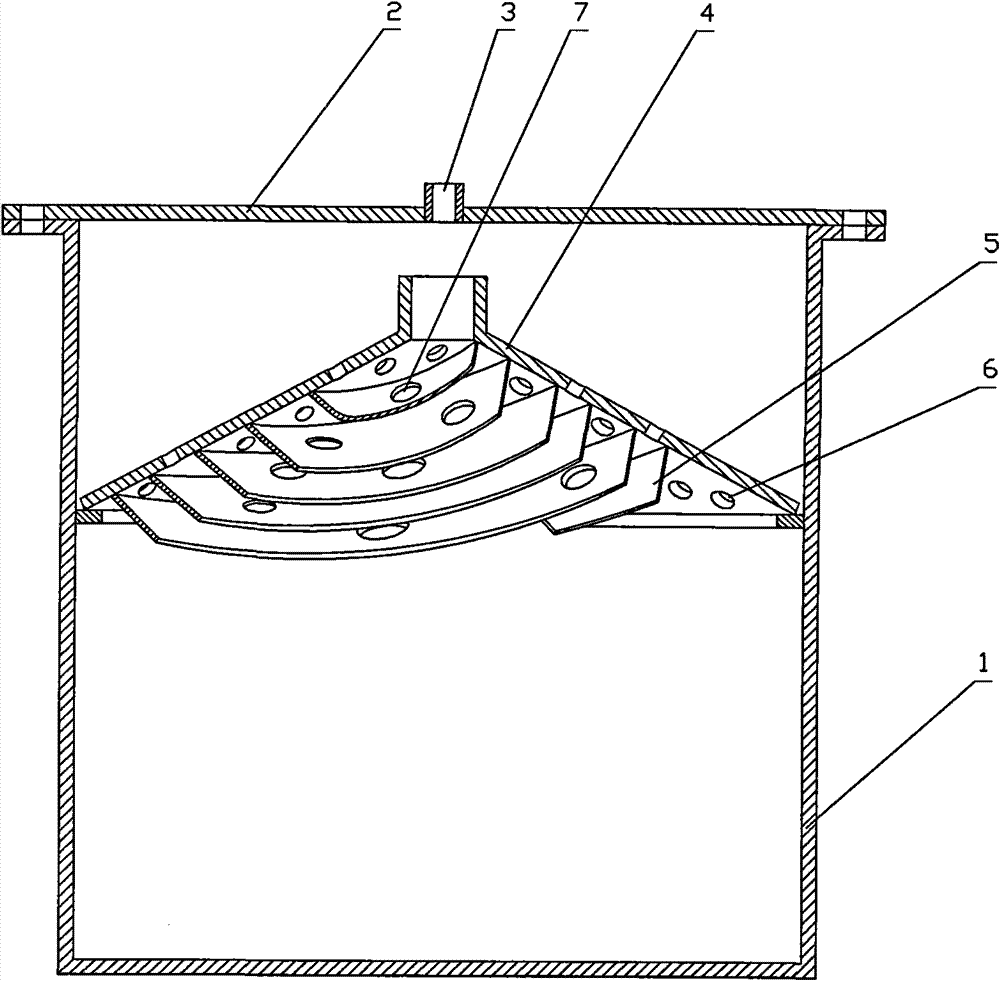

A reactor and encrustation technology, which is applied in the field of biogas reactors, can solve the problems of easily damaging the airtightness of biogas reactors, destroying the continuous use of biogas, and reducing the service life of fermentation tanks, and achieves obvious anti-encrusting performance and structural Simple, prolonged exposure effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Using 2000g potato skins as the fermentation substrate, and pretreating it for 7 days, collecting 2000ml of field sewage sludge strains. At room temperature of about 27℃, the biogas reaction with anti-crusting device and without anti-crusting device respectively The fermentation test in the vessel was 30 days, and the TS concentration of the fermentation raw material was 3%. In the fermentation cycle, the gas production rate of the biogas reactor with anti-crusting device is 0.248m 3 / (m 3 ·D), the raw material gas production rate is 223m 3 / (kg·TS), the wet weight of suspended solids is 6g, and the dry weight is 0.58g; the gas production rate of the biogas reactor without anti-crusting device is 0.211m 3 / (m 3 ·D), the raw material gas production rate is 190m 3 / (kg·TS), the wet weight of suspended solids is 181g, and the dry weight is 19.5g. By comparison, it was found that the gas production of the biogas reactor with anti-crusting device was increased by 17.5%; compar...

Embodiment 2

[0024] Take 2000ml of fermented biogas slurry as inoculum, and pretreat 2000g potato skins for 7 days as a fermentation substrate. Ferment in a reactor with anti-crusting device at room temperature about 27℃ for 30 days. The TS concentration of fermentation raw material is 6 %, the gas production rate of the biogas reactor with anti-crusting device is 0.882m 3 / (m 3 ·D), while the conventional fermentation tank is 0.3m 3 / (m 3 · D) It can be seen that the pool volume rate of the biogas reactor with anti-crusting device is increased by nearly 194%, and the raw material utilization rate is significantly improved. And there is almost no suspended solids on the liquid surface. The COD removal rate of biogas slurry is as high as 71.7%, and the raw material gas production rate is 600m 3 / (kg·TS), and the methane concentration in the produced gas exceeds 70%, and the produced gas is of high quality.

Embodiment 3

[0026] Take 2000ml of the fermented biogas slurry as the inoculum. Use 2000g potato peels as the fermentation raw material, pile up and pretreat for 7 days. When the temperature is about 27℃, add the anti-encrustation device and the non-anti-encrustation device. Biogas reactor, fermentation raw material TS concentration is 6%, fermentation for 30 days, the gas production of biogas reactor with anti-encrustation is 180200ml, and the gas production of biogas reactor without anti-encrustation device is 150170ml. The gas production of the biogas reactor of the crusting device increased by 19.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com