Circulating fluidized bed boiler and method for combusting by using yellow phosphorus exhausting gas

A technology of circulating fluidized bed and yellow phosphorus tail gas, which is applied in the direction of fluidized bed combustion equipment, combustion method, fuel burned in a molten state, etc., can solve the problem of inability to ensure safe operation of boilers, corrosion of boiler pressure components, and inability to resist smoke. Gas corrosion and other problems, to achieve the effect of low operation and maintenance costs, low cost, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

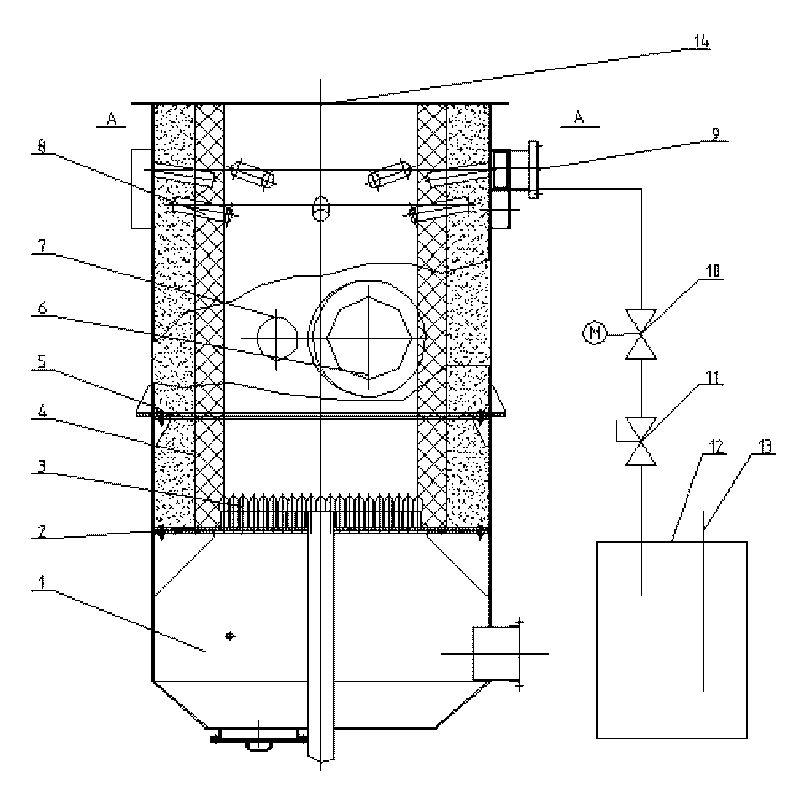

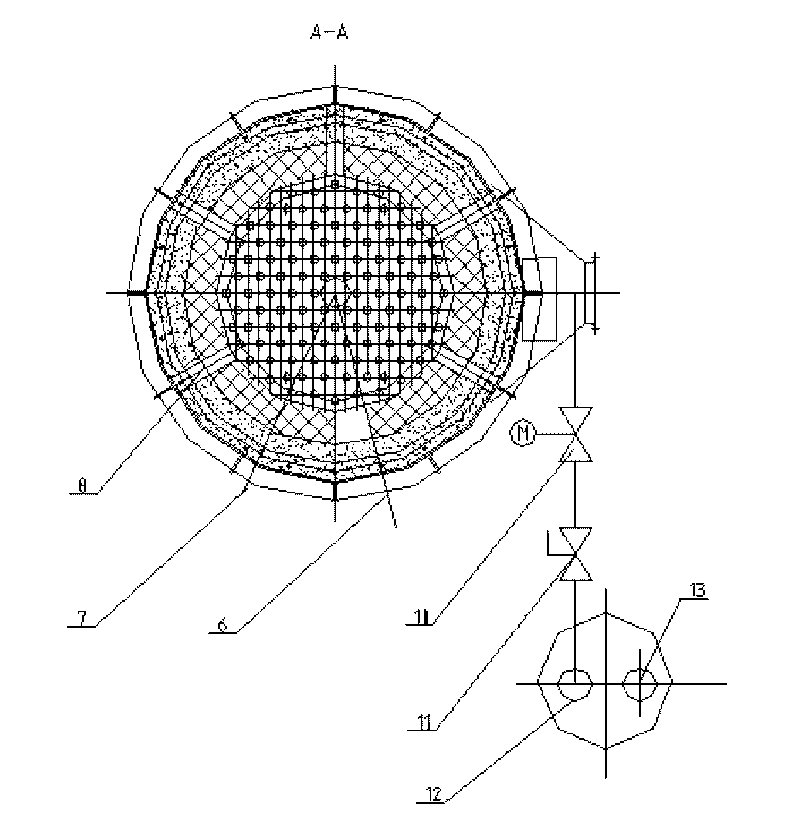

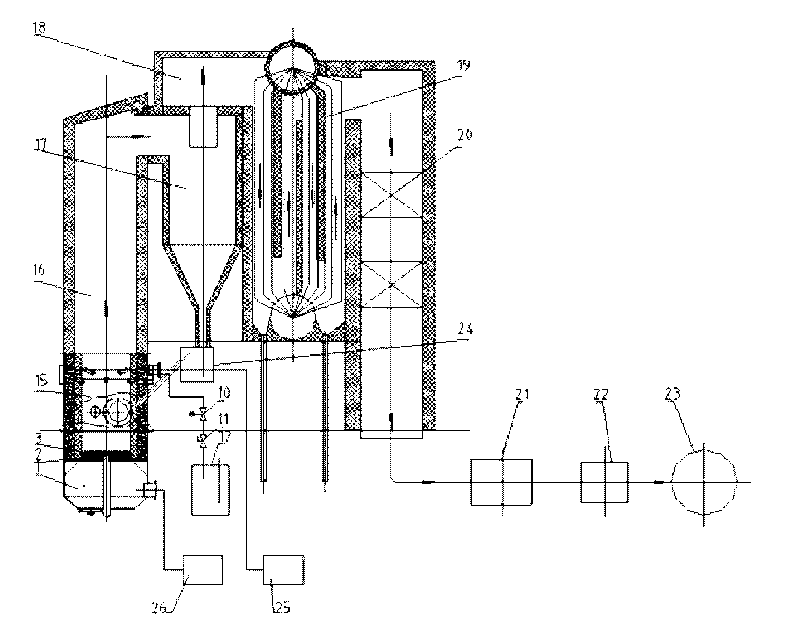

[0030] Such as Figure 1-3 , The circulating fluidized bed boiler includes a combustion chamber 15 and an equal-pressure air chamber 1 below it, and the air chamber is connected to a primary fan 26 . There is an air distribution plate 2 between the combustion chamber and the air chamber. The air distribution plate is equipped with a wind cap 3. The outer wall of the combustion chamber is covered with a refractory layer 4 and an insulation layer 5 in sequence. The outer wall is provided with a feed port leading to the combustion chamber. 7. Inspection hole 6. Yellow phosphorus tail gas inlet and secondary air inlet. The location of the secondary air inlet is higher than the yellow phosphorus tail gas inlet. The inlets for the yellow phosphorus tail gas are 6 inlets evenly distributed on the wall of the combustion chamber (the inlets for the yellow phosphorus tail gas can be increased or decreased according to actual needs), and each inlet for the yellow phosphorus tail gas is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com