Phase-change temperature testing system

A technology of testing system and phase change temperature, applied in the investigation stage/state change, etc., can solve the problems of measurement inaccuracy, light transmittance change, application range limitation, etc., achieve intuitive and reliable results, avoid measurement errors, and test reliable high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

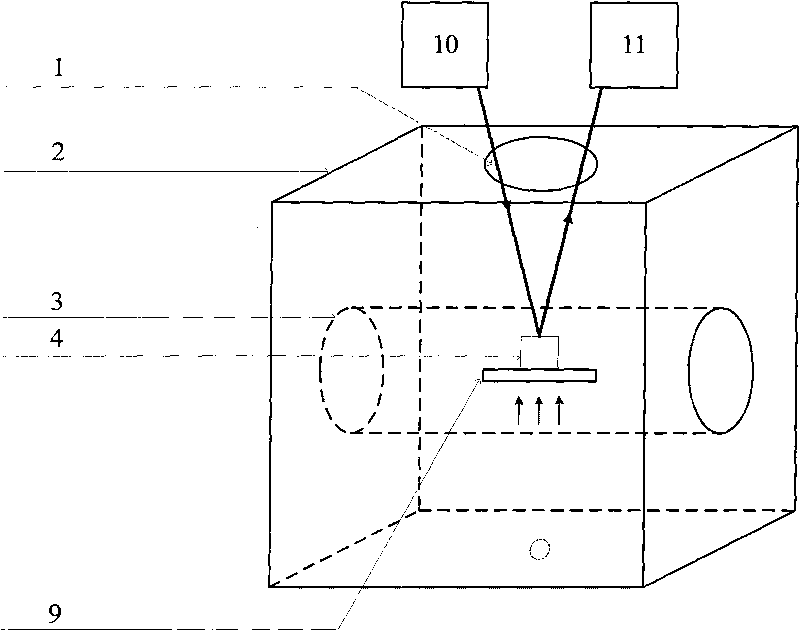

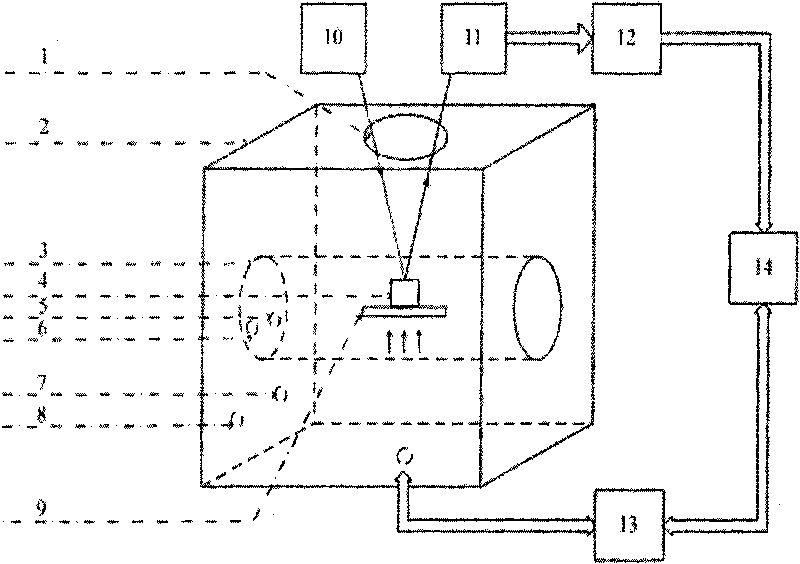

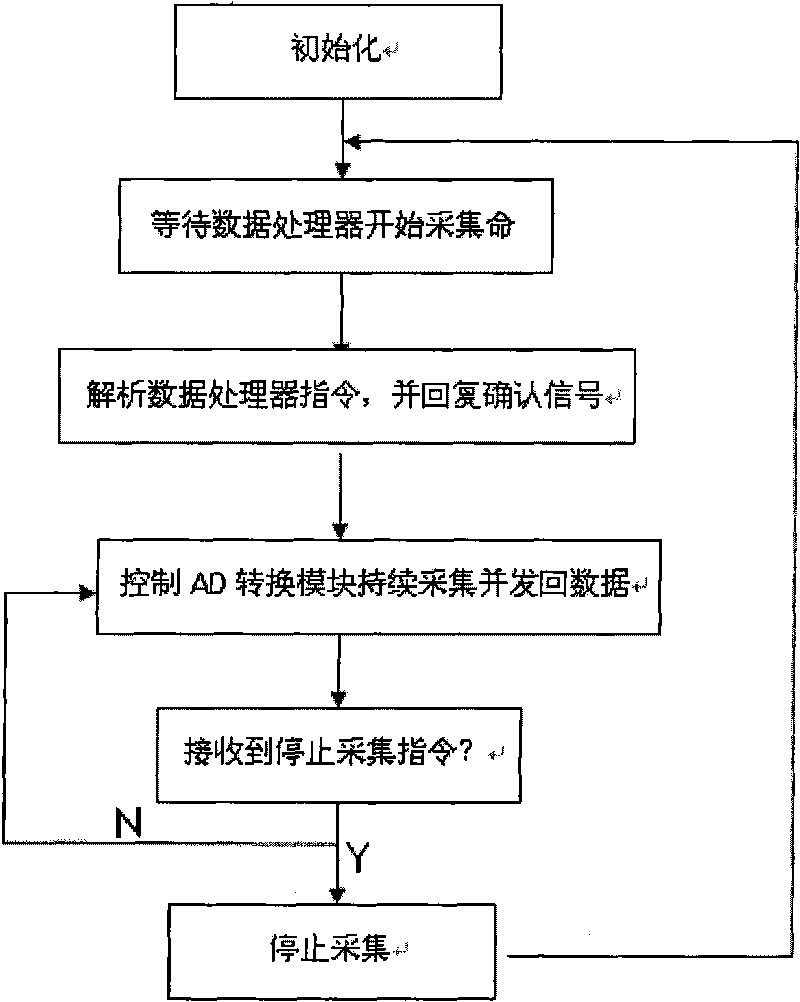

[0022] The working principle of this system is: the optical properties of thin film materials will have a large difference before and after the phase change. Taking the chalcogenide phase change material as an example, its crystalline state is an ordered state and has a large reflectivity to light; the amorphous state In a disordered state, the reflectivity of light is small, and the difference can be as high as 80%. During the test, the sample to be tested is heated in the vacuum heating furnace according to the set heating rate, a beam of constant power laser light is incident on the surface of the sample and reflected, the reflected light power is detected by the photodetector, the reflected light power and the actual incident light power The ratio of is the reflectance of the sample at a certain temperature point, from which the change of the reflectance of the sample with temperature can be obtained. After the corresponding temperature value and sample reflectance are col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com