Cathode active substance of lithium secondary battery and preparation method thereof

A negative electrode active material and secondary battery technology, applied in battery electrodes, electrode manufacturing, circuits, etc., can solve the problems of low specific capacity of batteries, achieve the effects of increased specific capacity, simple preparation process, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

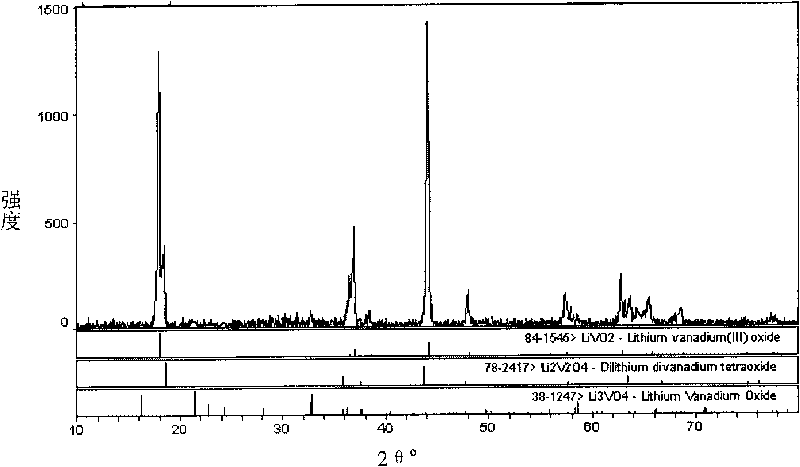

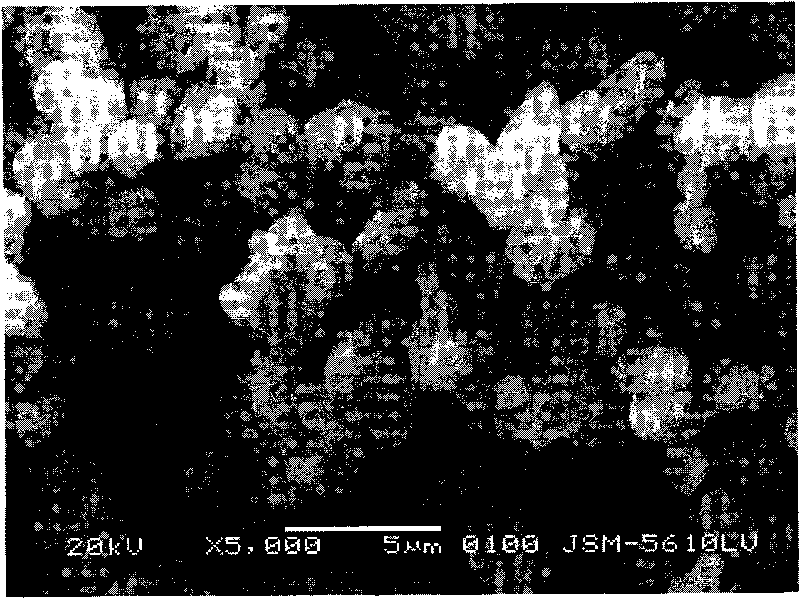

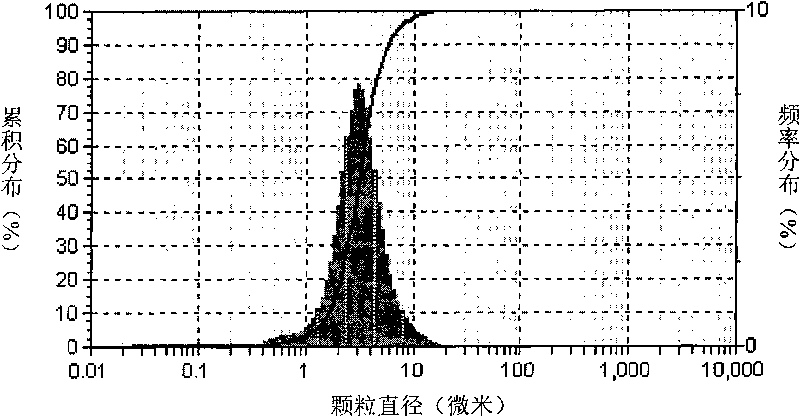

[0038] This example is used to illustrate the preparation of the negative electrode active material lithium vanadium oxide provided by the present invention.

[0039] 81.28 lithium carbonate, 163.69 grams of vanadium pentoxide, 45.6 grams of sucrose and 1.60 grams of titanium dioxide are placed in a ball mill jar, mixed with 280 milliliters of absolute ethanol, so that the reactant can be completely dispersed in ethanol, and the mixture is mixed on a planetary ball mill at 350 The precursor mixture was obtained after ball milling at a rotational speed of rpm for 15 hours. The precursor mixture was air-dried and ball-milled for a second time for 5 hours to obtain a dispersed powder. Put the obtained dispersed powder into a crucible, put it in an argon atmosphere protection heat treatment furnace, raise the temperature to 850°C, keep it warm for 15 hours, cool naturally to below 100°C, take it out, and obtain the negative electrode active material after sieving. The carbon cont...

Embodiment 2

[0042] This example is used to illustrate the preparation of the negative electrode active material lithium vanadium oxide provided by the present invention.

[0043] 81.28 grams of lithium carbonate, 163.69 grams of vanadium pentoxide, 52.85 grams of glucose and 1.60 grams of titanium dioxide are placed in a ball mill jar, mixed with 270 milliliters of absolute ethanol, so that the reactant can be completely dispersed in ethanol, and placed on a planetary ball mill with The precursor mixture was obtained after ball milling at 350 rpm for 15 hours. The precursor mixture was air-dried and milled twice for 5 hours to obtain a dispersed powder. Put the obtained dispersed powder into a crucible, put it in an argon atmosphere protection heat treatment furnace, raise the temperature to 800°C, keep it warm for 15 hours, cool it naturally to below 100°C, take it out, and obtain the negative electrode active material after sieving. The carbon content in the produced negative electrode...

Embodiment 3

[0045] This example is used to illustrate the preparation of the negative electrode active material lithium vanadium oxide provided by the present invention.

[0046] Put 81.28 grams of lithium carbonate, 163.69 grams of vanadium pentoxide, 19.2 grams of PH15B graphite and 1.60 grams of titanium dioxide in a ball mill jar and mix them with 290 milliliters of absolute ethanol so that the reactants can be completely dispersed in ethanol. The precursor mixture was obtained after ball milling at 350 rpm for 15 hours. The precursor mixture was air-dried and milled twice for 5 hours to obtain a dispersed powder. Put the obtained dispersed powder into a crucible, put it in an argon atmosphere protection heat treatment furnace, raise the temperature to 850°C, keep it warm for 12 hours, cool it naturally to below 100°C, take it out, and obtain the negative active material after sieving. The carbon content in the produced negative electrode active material was 3.8% by weight. Li 2 V ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com