Method for improving electrochemical properties of hydrogen storage alloy powder by using polyaniline

A hydrogen storage alloy, electrochemical technology, applied in the direction of circuits, electrical components, battery electrodes, etc., can solve the problems of strong molecular bonds, poor rigidity and strong interaction, difficult to melt processing, difficult to achieve alloy performance, etc., to achieve low production cost, The operation process and process are simple, and the effect of simple mechanical filtration and recovery treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1) Prepare 100g containing aniline 0.5mol / l, sulfuric acid 2×10 -3 mol / l mixed solution;

[0017] 2) Add 20g AB to the aforementioned mixed solution 5 type (MlNi 4.19 mn 0.31 co 0.42 al 0.23 ) hydrogen storage alloy powder;

[0018] 3) Stirring for 8 minutes under the condition of 120 rpm in the air;

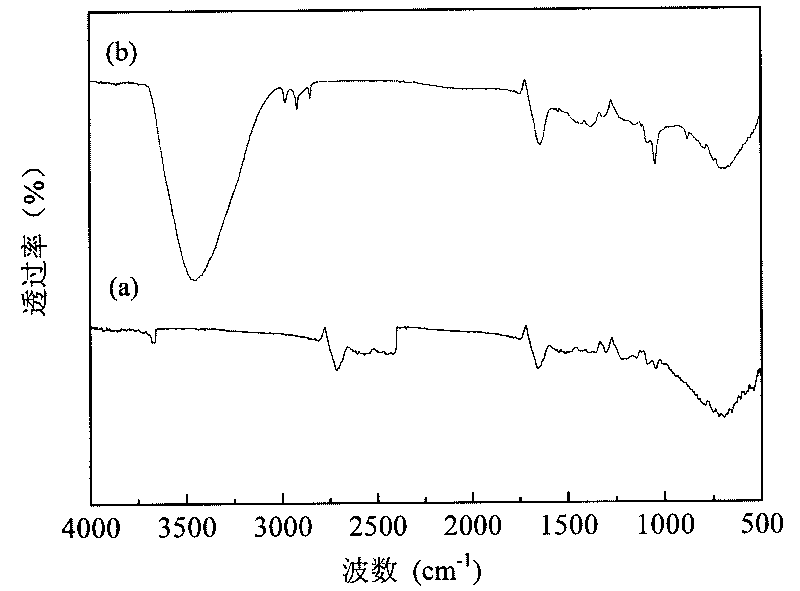

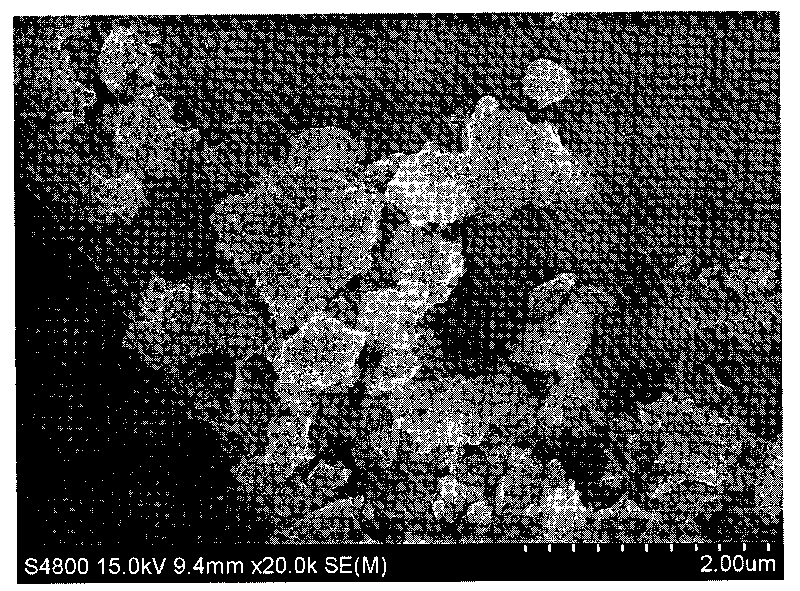

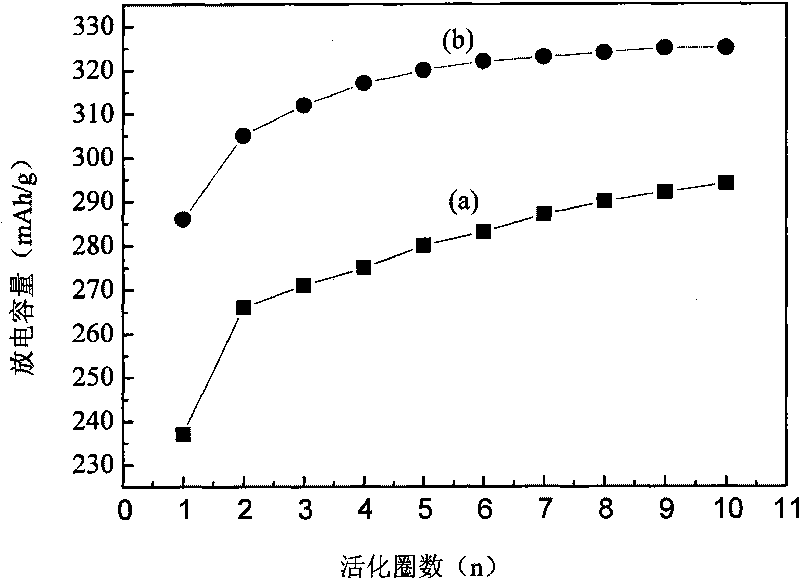

[0019] 4) The treated alloy powder was characterized by Fourier transform infrared spectroscopy and field emission scanning electron microscopy, the results are shown in the attached figure 1 with figure 2 , as can be seen in the figure: in the Fourier Transform Infrared Spectrum, the characteristic peaks of benzoquinone (N=Q=N) and carbon-carbon double bond (C=C) of polyaniline appearing in the alloy after treatment are 1168cm -1 、3200cm -1 , it can be found in the field emission scanning electron microscope that coral-like polyaniline is formed on the surface of the alloy. The treated alloy powder is made into the negative electrode of the hydrogen storage el...

Embodiment 2

[0021] 1) Prepare 100g containing aniline 0.3mol / l, sulfuric acid 3×10 -3 mol / l mixed solution;

[0022] 2) Add 30g AB to the aforementioned mixed solution 5 type (MlNi 3.67 mn 0.25 co 0.50 al 0.28 ) hydrogen storage alloy powder;

[0023] 3) Stirring for 10 minutes at a speed of 150 rpm in air;

[0024] 4) The treated alloy powder was characterized by Fourier transform infrared spectroscopy and field emission scanning electron microscopy. The experimental results showed that: in the Fourier transform infrared spectrum, the treated alloy appeared benzoquinone (N=Q=N), carbon Carbon double bond (C=C) characteristic peak is 1163cm -1 、3195cm -1 , it can be found in the field emission scanning electron microscope that coral-like polyaniline is formed on the surface of the alloy. The treated alloy powder was made into an electrode for electrochemical testing, and the experimental conditions were the same as in Example 1. The experimental results show that the number of a...

Embodiment 3

[0026] 1) Prepare 100g containing aniline 0.5mol / l, sulfuric acid 4×10 -3 mol / l mixed solution;

[0027] 2) Add 50gAB to the aforementioned mixed solution 3 Type (La 0.88 Mg 0.12 Ni 2.95 mn 0.10 co 0.55 al 0.10 ) hydrogen storage alloy powder;

[0028] 3) Stirring for 15 minutes at a speed of 200 rpm in air;

[0029] 4) The treated alloy powder was characterized by Fourier transform infrared spectroscopy and field emission scanning electron microscopy. The experimental results showed that: in the Fourier transform infrared spectrum, the treated alloy appeared benzoquinone (N=Q=N), carbon Carbon double bond (C=C) characteristic peak is 1170cm -1 、3206cm -1, it can be found in the field emission scanning electron microscope that coral-like polyaniline is formed on the surface of the alloy. The treated alloy powder was made into an electrode for electrochemical testing, and the experimental conditions were the same as in Example 1. The experimental results show that t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electric properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com