Cream and making method and use thereof

A production method and cream technology, applied in the field of cream, can solve the problems of short shelf life, inconvenience for long-distance transportation, and restricting the sales area of cream

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

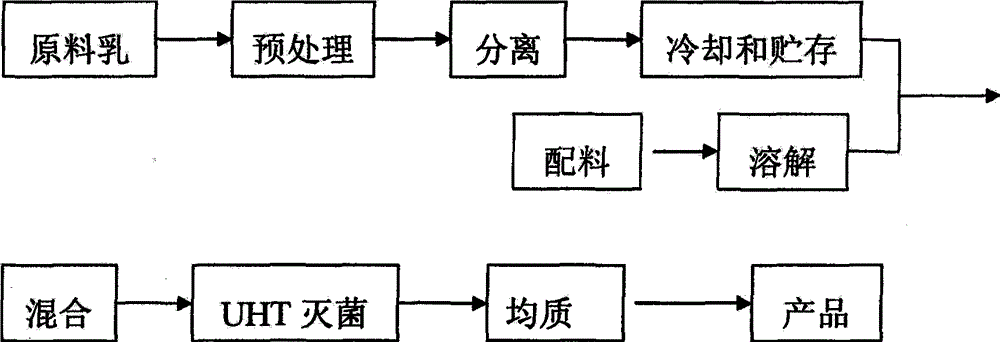

Method used

Image

Examples

Embodiment 1

[0044] Ingredients according to 1 ton of production:

[0045]

[0046] Preparation:

[0047] (1) Raw milk pretreatment: After the raw milk is filtered and cleaned, it is pasteurized by using a plate heat exchanger. The pasteurization treatment conditions are 72°C, 15s.

[0048] (2) Centrifugal separation: use a separator to centrifugally separate the cream; the rotating speed of the separator is 7200rpm, and the separation temperature is 50°C. The isolated cream had a fat content of 50%.

[0049] (3) Cooling and storage: the separated cream is cooled to 12°C by a plate heat exchanger and stored for later use.

[0050] (4) Raw material mixing:

[0051] ①According to the formula in the above table, use a gouache mixer to dissolve the degreasing powder with water at a temperature of 40°C and stir to dissolve thoroughly; then add guar gum and starch to the gouache mixer, stir to dissolve thoroughly and then stir for 10 minutes; then add to the gouache Add soybean lecithin,...

Embodiment 2

[0059] Ingredients according to 1 ton of production:

[0060]

[0061] Preparation:

[0062] (1) Raw milk pretreatment: After the raw milk is filtered and cleaned, it is pasteurized by using a plate heat exchanger. The pasteurization treatment conditions are 72°C, 15s.

[0063] (2) Centrifugal separation: use a separator to centrifugally separate the cream; the rotating speed of the separator is 7000rpm, and the separation temperature is 45°C. The isolated cream had a fat content of 50%.

[0064] (3) Cooling and storage: the separated cream is cooled to 10°C by a plate heat exchanger and stored for later use.

[0065] (4) Raw material mixing:

[0066] ① According to the formula in the above table, use a gouache mixer to dissolve sodium carboxymethyl cellulose, microcrystalline cellulose, and carrageenan with water, stir to dissolve thoroughly and then stir for 8 minutes; then add soybean lecithin to the gouache mixer, stir to dissolve thoroughly and then stir 12 minute...

Embodiment 3

[0074] Ingredients according to 1 ton of production:

[0075]

[0076] Preparation:

[0077] (1) Raw milk pretreatment: After the raw milk is filtered and cleaned, it is pasteurized by using a plate heat exchanger. The pasteurization treatment conditions are 72°C, 15s.

[0078] (2) Centrifugal separation: use a separator to centrifugally separate the cream; the rotating speed of the separator is 6500rpm, and the separation temperature is 55°C. The isolated cream had a fat content of 50%.

[0079] (3) Cooling and storage: the separated cream is cooled to 10°C by a plate heat exchanger and stored for later use.

[0080] (4) Raw material mixing:

[0081] ①According to the formula in the above table, use a gouache mixer to dissolve the degreasing powder with water at a temperature of 45°C, stir and dissolve thoroughly; then add guar gum, locust bean gum, and starch to the gouache mixer, stir to dissolve thoroughly, and then stir for 15 minutes ; Soybean lecithin, Tween 80,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com