Method for recovering hydrogen from tail gas containing chlorsilane

A technology of chlorosilane and tail gas, applied in the field of gas separation, can solve the problems of high cost, high impurity content, high energy consumption, etc., and achieve the effect of reducing pressure requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment is a 9-tower pressure swing adsorption method for recovering hydrogen from trichlorosilane tail gas (raw material tail gas), and the flow rate of raw material tail gas is about 200Nm 3 / Hr, the adsorption pressure is about 0.6MpaG; the composition of raw material tail gas is as shown in the following table 2:

[0031] The composition of table 2 embodiment 1 raw material tail gas

[0032] components

H 2

HCl

SiHCl 3 、SiCl 4 、SiH 2 Cl 2

N 2

Composition (V%)

79.00

17.84

2.97

0.19

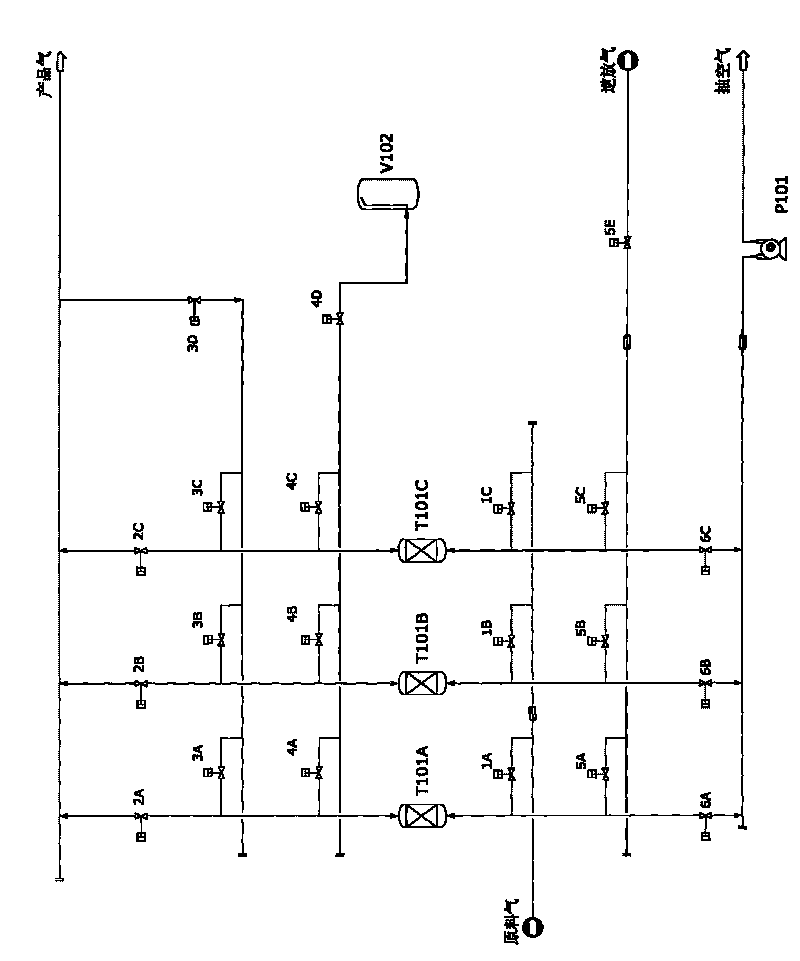

[0033] In this embodiment, the pressure swing adsorption system is divided into 3 sections (series connection), which are connected by a total of 9 adsorption towers, 3 vacuum pumps, and corresponding program-controlled valves and pipelines. The process flow of each stage is as follows figure 1 As shown, where T201A / B / C is the adsorption tower, V201 is the buffer tank, P201 is the vacuum pump, 1A / B / C, 2A / B / C,...

Embodiment 2

[0041] This embodiment is a 12-tower pressure swing adsorption method for recovering hydrogen from trichlorosilane tail gas (raw material tail gas), and the flow rate of raw material tail gas is about 600Nm 3 / Hr, the adsorption pressure is about 0.5MpaG; the composition of raw material tail gas is as shown in the following table 4:

[0042] The composition of table 4 embodiment 2 raw material tail gas

[0043] components

H 2

HCl

SiHCl 3 、SiCl 4 、SiH 2 Cl 2

N 2

Composition (V%)

79.00

17.84

2.97

0.19

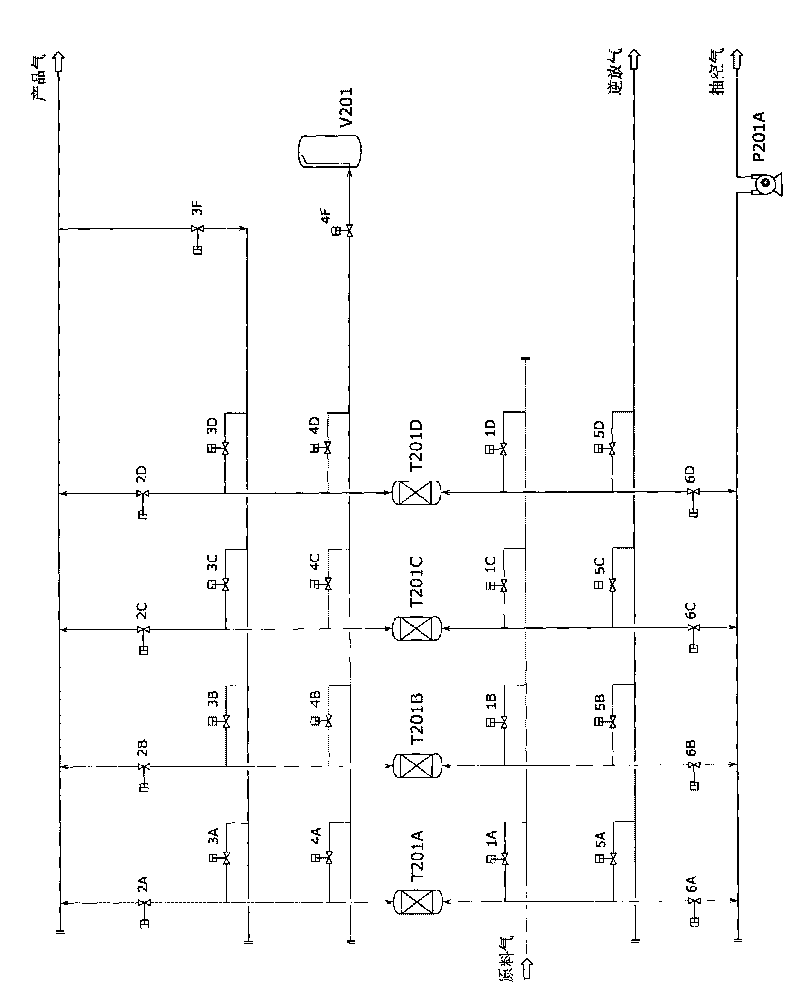

[0044] In this embodiment, the pressure swing adsorption system is divided into 3 sections (series connection), which are connected by a total of 12 adsorption towers, 3 vacuum pumps, and corresponding program-controlled valves and pipelines.

[0045] The process flow of each stage is as follows figure 2 As shown, where T201A / B / C / D is the adsorption tower, V201 is the buffer tank, P201A is the vacuum pump, ...

Embodiment 3

[0053] This embodiment is an 18-tower pressure swing adsorption method for recovering hydrogen from trichlorosilane tail gas (raw material tail gas), and the flow rate of raw material tail gas is about 600Nm 3 / Hr, the adsorption pressure is about 0.7MpaG; the composition of raw material tail gas is as shown in the following table 6:

[0054] The composition of table 6 embodiment 3 raw material tail gas

[0055] components

H 2

HCl

SiHCl 3 、SiCl 4 、SiH 2 Cl 2

N 2

Composition (V%)

79.00

17.84

2.97

0.19

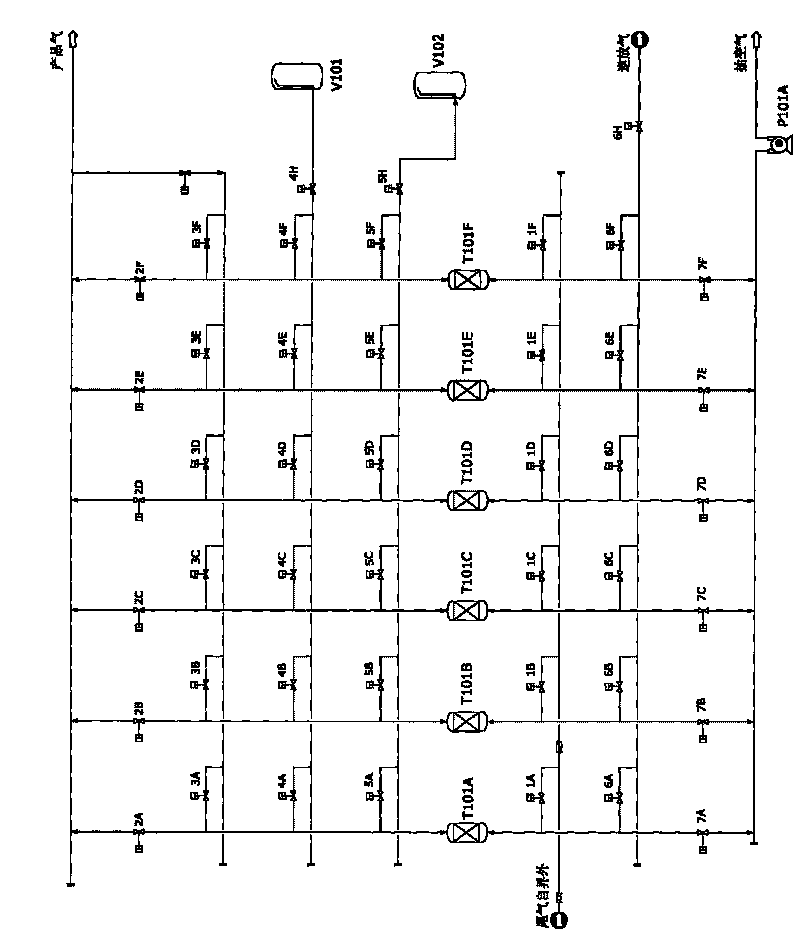

[0056] In this embodiment, the pressure swing adsorption system is divided into 3 sections (series connection), which are connected by a total of 18 adsorption towers, 3 vacuum pumps, and corresponding program-controlled valves and pipelines.

[0057] The process flow of each stage is as follows image 3 As shown, where T101A~F are adsorption towers, V101 and V102 are buffer tanks, P101A is vacuum pump, 1A~...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com