Method for electrolytically machining complex case type surface

A complex and electrode technology, applied in the field of electrolytic machining of complex casing profiles, can solve the problems of large impact on the service life of the machine tool, large residual stress on the surface of the material, and difficulty in cutting materials, so as to avoid high processing costs and high electrode utilization. , the effect of simplifying the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

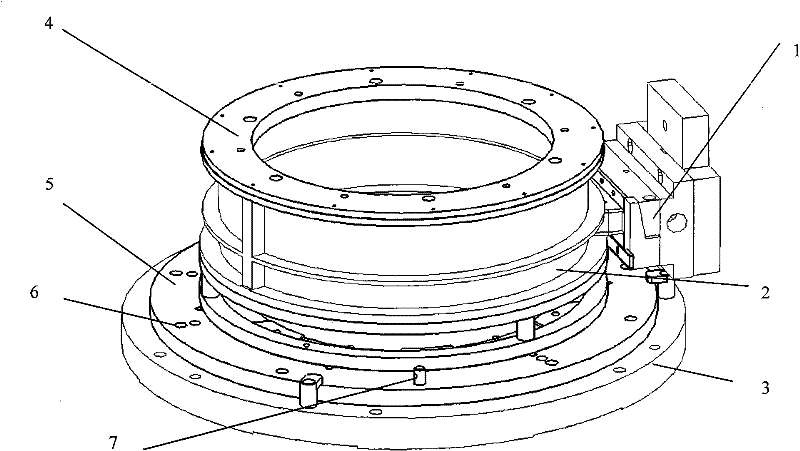

[0044] The structure of the ring forging blank is as follows: Figure 12 shown. The material of the ring-shaped forging blank is GH907, the heat treatment HB≥285, the weight is 90kg, the shape is a ring-shaped surface, turned and formed, the diameter is 572mm, and the surface roughness is Ra6.3μm.

[0045] The structure of casing parts is as follows: Figure 13 As shown, there are 2 annular flanges 15, 1 short longitudinal flange 16, and 2 longitudinal flanges 17 distributed symmetrically with the casing parts axis on the outer surface. The depth of electrolytic machining is 15mm, and the surface roughness value is Ra1.6μm.

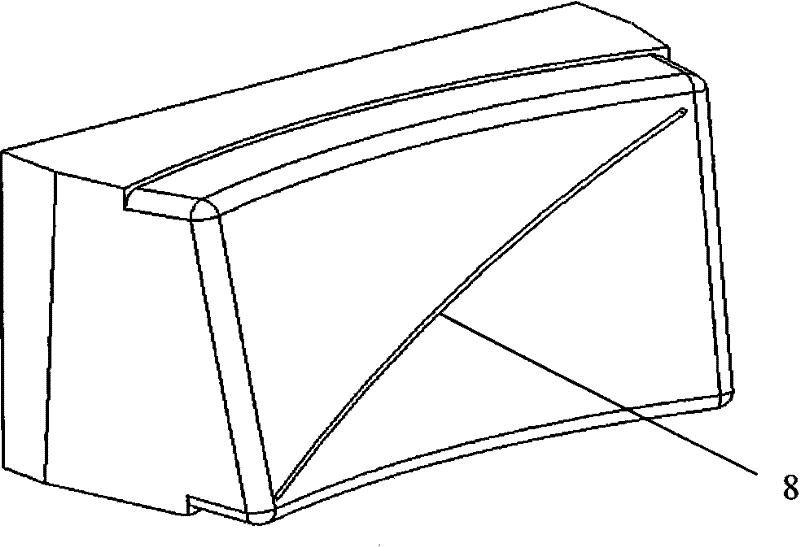

[0046] For the indexing and division of the casing profile, see Figure 14 , 15 , Shown in 16, the selected electrode corresponds to the block. The outer surface of the casing is divided into upper and lower parts for processing, see K-K section, the upper part of the workpiece is divided into 10 pieces with equal angles, processed with 1# electrode,...

Embodiment 2

[0058] The structure of the circular forging blank is the same as in Example 1.

[0059] The structure of casing parts is the same as in Embodiment 1.

[0060] The indexing, dividing, grouping and sub-operations of casing profile processing are the same as in embodiment 1.

[0061] The fixing method and positioning method of the forging blank on the fixture are the same as in Embodiment 1.

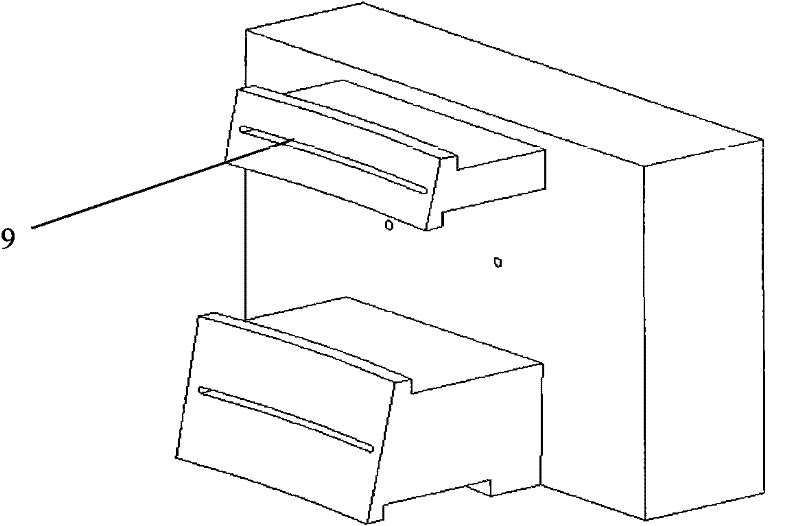

[0062] The difference is: the 1# electrode has a horizontal curve increasing fluid outlet. The width of the water outlet is b1=2mm, the depth d=15mm, rounded along the periphery of the water outlet, the radius of rounding is r=0.5mm, and the surface roughness Ra is 0.8μm. The diameter of the circular holes at both ends is Φ3mm, and the transitional arc R between the circular hole and the long side is 30mm. The size increase of the front end working surface of the electrode is Δ1=0.3mm. The size reduction of the electrode side working surface is Δ2=0.5mm, and the inclination angle β=5°....

Embodiment 3

[0065] Blank structure such as Figure 17 shown. The blank material is GH706 nickel-based superalloy, heat treatment HB≥285, and the blank weighs about 85kg. The diameter of the large end circle of the cone is Φ720mm, the height is 158mm, and the taper is 10°. Turning processing molding, surface roughness value Ra3.2μm.

[0066] The structure of casing parts is as follows: Figure 18 shown. There are two large square bosses with the same shape and one small square boss on the outer ring profile, which are distributed at different angles along the circumference. Two longitudinal flanges are symmetrically distributed, and there are 1 annular flange at the upper and lower ends. place. The depth of electrolytic machining is 15mm, and the surface roughness value is Ra1.6μm.

[0067] For the indexing and division of the casing profile, see Figure 19 shown. The outer surface of the casing is divided into 16 pieces, and the selected electrodes correspond to the pieces. The 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com