Nano silica dioxide heat-insulating material and preparation method thereof

A technology of nano-silica and heat-insulating materials, applied in the field of nano-silica heat-insulating materials and its preparation, silicon dioxide heat-insulating materials and its preparation, can solve the problems of complex preparation process, poor environmental friendliness, and many organic components. Achieve the effects of simple preparation process, good environmental friendliness and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

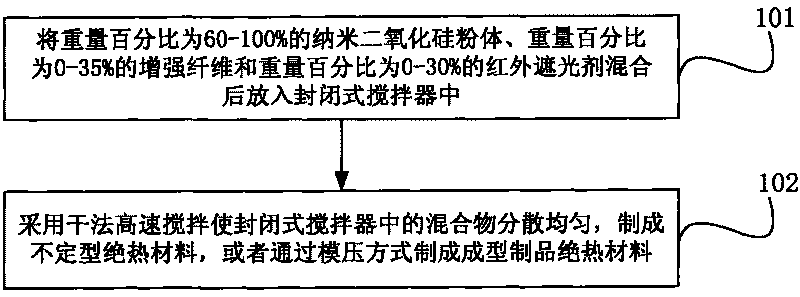

[0022] Such as figure 1 Shown is a flow chart of an embodiment of a method for preparing a nano-silica thermal insulation material of the present invention, the method comprising:

[0023] Step 101, mixing 60-100% by weight of nano-silica powder, 0-35% by weight of reinforcing fibers and 0-30% by weight of infrared light shielding agent, and then putting them into a closed mixer ;

[0024] Wherein, the optimum weight percent of the nano-silica powder put into the closed stirrer is 70-98%, the optimum weight percent of the reinforcing fiber is 2-25%, and the optimum weight percent of the infrared shading agent is 0. -25%; the above-mentioned silica powder can be flame silica fume, fumed silica, biological silica, silica airgel powder, hollow fiber-shaped silica prepared by asbestos acid etching, etc., and it can Comm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com