Method for synthesizing gamma-lactone and perfume processing method thereof

A synthesis method and technology of lactone, which is applied in the field of synthesis of γ-lactone, can solve the problems of affecting quality, complicated reaction and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

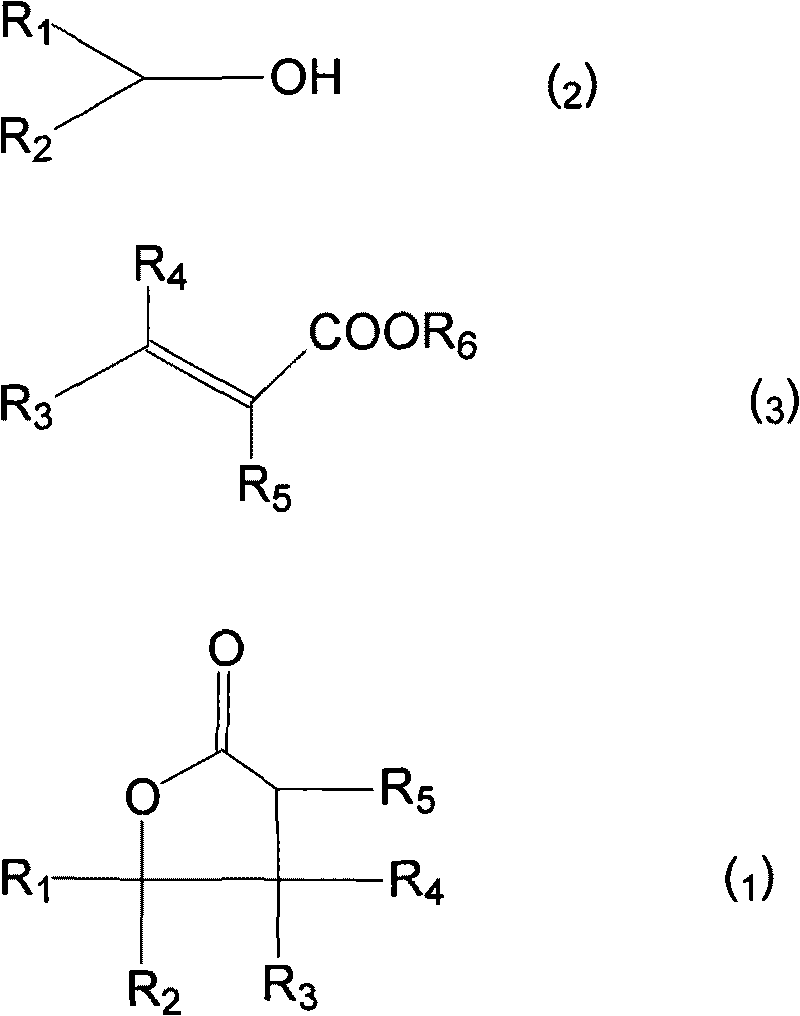

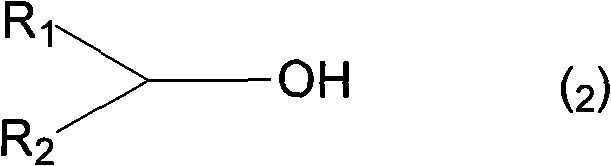

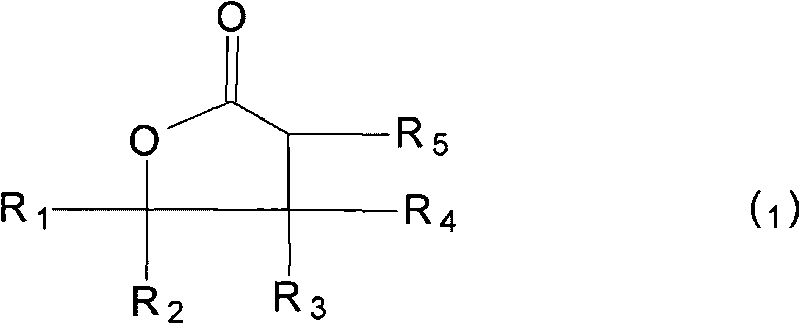

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: Synthesis of γ-propyl-γ-butyrolactone

[0033] In the reactor equipped with stirrer, condenser, thermometer and dropping device, add 222 grams (3.0 moles) of butanol, heat it to reflux, and add dropwise over 7 hours while stirring. The mixed solution of 74 grams (1.0 mole) of butanol, 86 g (1.0 mole) of methyl acrylate and 58 grams (0.3 mole) of tert-butyl peroxybenzoate, continue to react at this temperature for 3 hours after completion of the dropwise addition, then cool down To room temperature, recover excess butanol, and then carry out rectification under reduced pressure to obtain 75.5 g of γ-propyl-γ-butyrolactone, and the calculated yield is 59.0%.

Embodiment 2

[0034] Embodiment 2: Synthesis of γ-hexyl-γ-butyrolactone

[0035] In a reactor equipped with a stirrer, a condenser, a thermometer and a dropping device, add 348 grams (3.0 moles) of heptanol, heat it to 160°C, and drop it over 7 hours while stirring. Add the mixed solution of 116 grams (1.0 moles) of heptanol, 86 g (1.0 moles) of methyl acrylate and 39 grams (0.2 moles) of tert-butyl peroxybenzoate, continue to react at this temperature for 3 hours after completion of the dropwise addition, and then Cool down to room temperature, recover excess heptanol, and then carry out rectification under reduced pressure to obtain 153 g of γ-hexyl-γ-butyrolactone, and the calculated yield is 90.0%.

Embodiment 3

[0036] Embodiment 3: Synthesis of γ-pentyl-γ-butyrolactone

[0037] In a reactor equipped with a stirrer, a condenser, a thermometer and a dropping device, add 306 grams (3.0 moles) of hexanol, heat it to 150°C, and drop it over 7 hours while stirring. Add the mixed solution of 102 grams (1.0 mole) of hexanol, 72 g (1.0 mole) of acrylic acid and 39 grams (0.2 mole) of tert-butyl peroxybenzoate, continue to react at this temperature for 3 hours after the dropwise addition, then cool down to At room temperature, excess heptanol was recovered, and then rectified under reduced pressure to obtain 138.8 g of γ-pentyl-γ-butyrolactone, and the calculated yield was 89.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com