Preparation method of non-crystalline grains reinforced aluminium-base composite material by means of explosive compaction

A technology for strengthening aluminum matrix and composite materials, applied in the field of explosive processing, can solve the problems of high preparation cost, multiple manpower, material and financial resources, etc., and achieve the effects of low cost, elimination of bending effects, and prevention of macroscopic cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

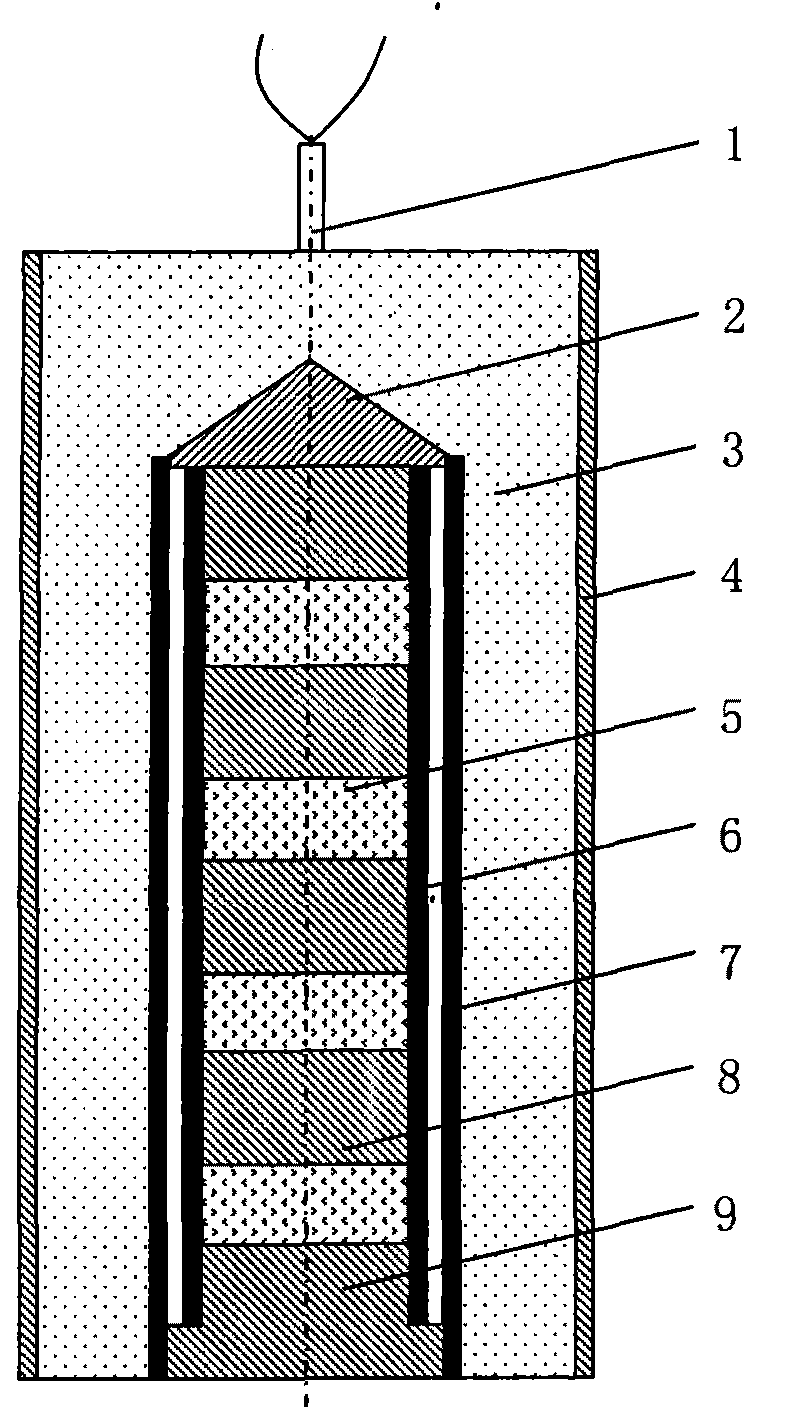

Embodiment 1

[0024] Fe-based amorphous powder (purity 99.5%, particle size 200 mesh) is used as the reinforcing phase, and its composition is: Fe63.3%, W15.36%, Mo10.95%, Ni5.43%, Cr3.56%, Si1. 28%. The amorphous powder is mixed with Al powder (99%, 325 mesh) at a mass fraction of 5%. Use an XQM-2L planetary ball mill to make it evenly mixed, and this process lasts for 4 hours with a rotating speed of 80rpm. Inner tube 6 has an inner diameter of 26mm and an outer diameter of 29mm, an outer tube 7 with an inner diameter of 33mm and an outer diameter of 37mm, and the distance between the inner and outer tubes is 2mm. After welding the inner tube 6, the outer tube 7 and the steel lower end plug 9, the powder is loaded and the mixed powder is loaded. 5 thickness 10mm, powder porosity 36.4%, 3 layers of steel pad 8, diameter 25.6mm, height 5mm, PVC upper end plug 2 is placed on the upper end of the device to adjust the waveform, the upper end plug cone angle is 120 degrees, explosive 3 thickne...

Embodiment 2

[0026] The mass fraction of amorphous powder is 30%, the inner diameter of the inner tube 6 is 26 mm, the outer diameter is 30 mm, the inner diameter of the outer tube 7 is 40 mm, the outer diameter is 45 mm, the distance between the inner and outer tubes is 5 mm, and two layers of steel pads 8 are set, with a diameter of 25.6 mm. The height is 10mm, the thickness of the explosive 3 is 48mm, and other conditions are the same as in Example 1 to obtain 3 samples with a diameter of 23.8mm and a height of 8.6mm.

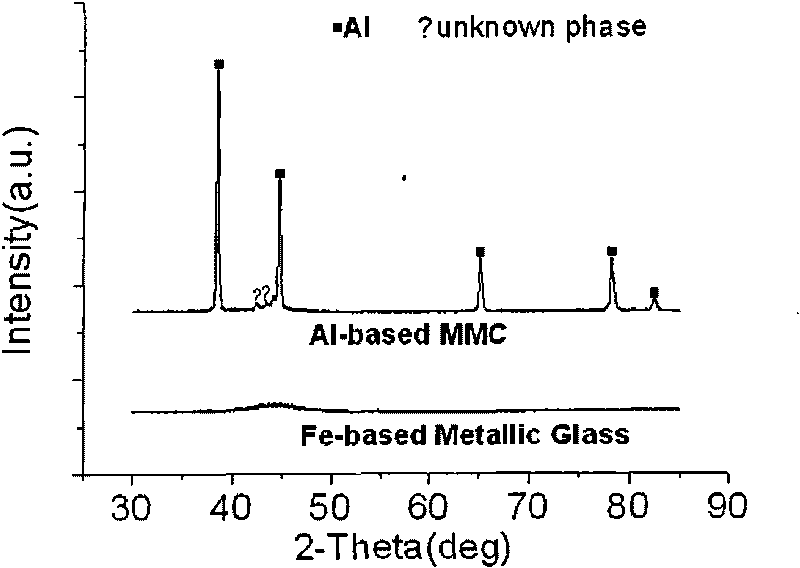

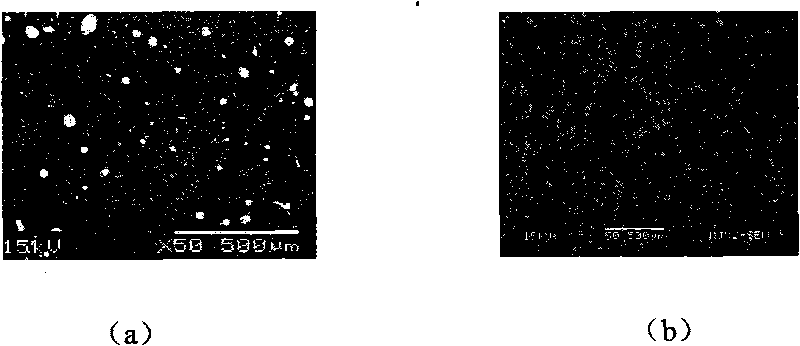

[0027] The X-ray diffraction (XRD) test results of the compacted parts showed that the amorphous reinforcement in the composite material did not crystallize during the explosive compaction (such as figure 2 shown); as image 3Shown are the scanning electron microscope (SEM) photographs of the amorphous particle-reinforced Al-based composite material with amorphous mass fractions of 5% and 30%, respectively. Observation shows that the amorphous reinforcement is uniformly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com