Whey protein/gelatin edible compound film and preparation method thereof

A whey protein and composite film technology is applied in the field of food packaging materials to achieve the effects of good oil resistance, low price and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

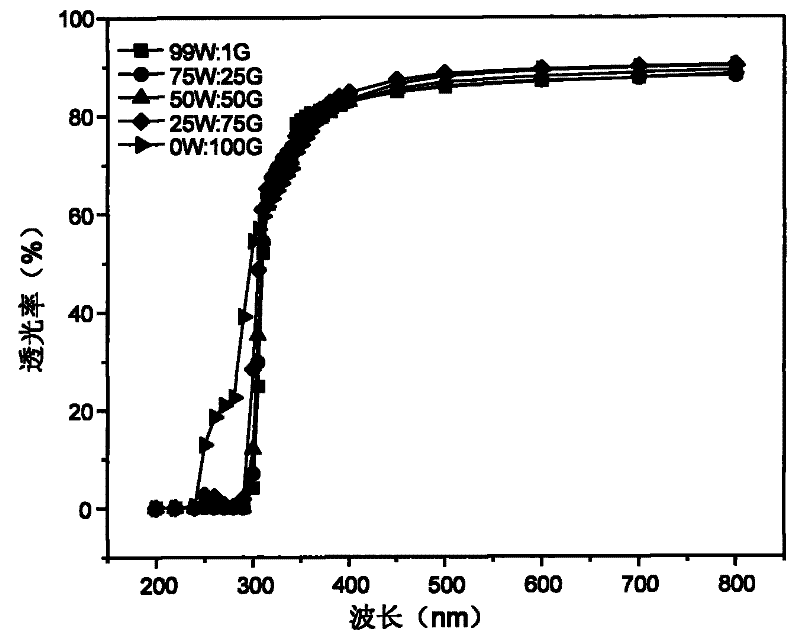

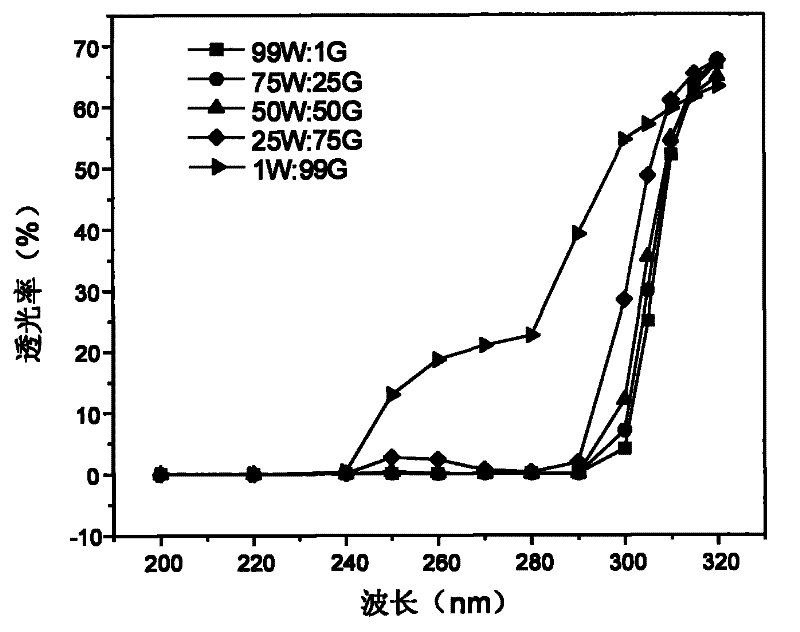

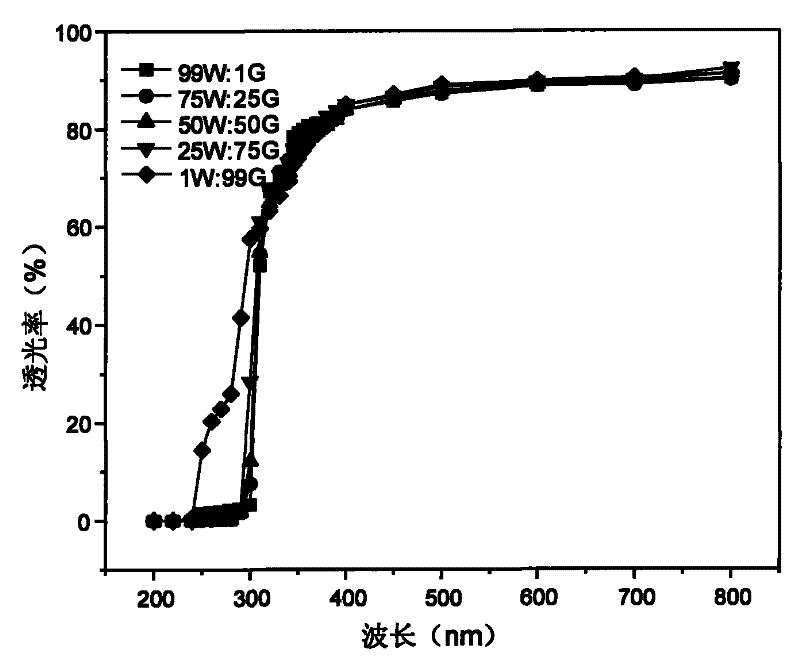

Image

Examples

Embodiment 1

[0045] (1) Preparation of whey protein isolate solution: Weigh whey protein powder, add deionized water, stir for 2 hours to fully dissolve, adjust pH to 8, heat in a water bath at 80°C for 30 minutes, and cool to Room temperature, wherein the mass percent concentration of the WPI solution is 10%.

[0046] (2) Preparation of gelatin solution: Weigh gelatin powder, add deionized water, swell at room temperature for 30 minutes, heat in a 55°C water bath for 15 minutes to fully dissolve, cool to room temperature, adjust the solution to pH8, and prepare the gelatin solution The mass percent concentration is 10%.

[0047] (3) The above two solutions are mixed, wherein the mass ratio of whey protein isolate to gelatin is shown in Table 1, and then glycerin is added, wherein the quality of glycerin is 0.4 in ratio to the sum of the mass of whey protein isolate and gelatin : 1, stirred at room temperature to make it fully mixed, ultrasonically degassed to obtain a film-forming liquid...

Embodiment 2

[0055] (1) Preparation of whey protein isolate solution: Weigh whey protein powder, add deionized water, stir for 2 hours to fully dissolve, adjust pH to 7, heat in a water bath at 90°C for 20 minutes, and cool to Room temperature, wherein the mass percent concentration of the WPI solution is 8%.

[0056] (2) Preparation of gelatin solution: Weigh gelatin powder, add deionized water, swell at room temperature for 30 minutes, heat in a 35°C water bath for 30 minutes to fully dissolve, cool to room temperature, adjust the solution to pH7, and prepare the gelatin solution The mass percent concentration is 8%.

[0057] (3) The above two solutions are mixed, wherein the mass ratio of whey protein isolate to gelatin is shown in Table 2, and then glycerin is added, wherein the ratio of the quality of glycerol to the sum of the mass of whey protein isolate and gelatin is 0.5 : 1, stirred at room temperature to make it fully mixed, ultrasonically degassed to obtain a film-forming liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com